Innovating how industries manufacture everyday products

ASU researcher Xiangjia “Cindy” Li receives an NSF CAREER award for an electrically assisted multimaterial 3D printing approach

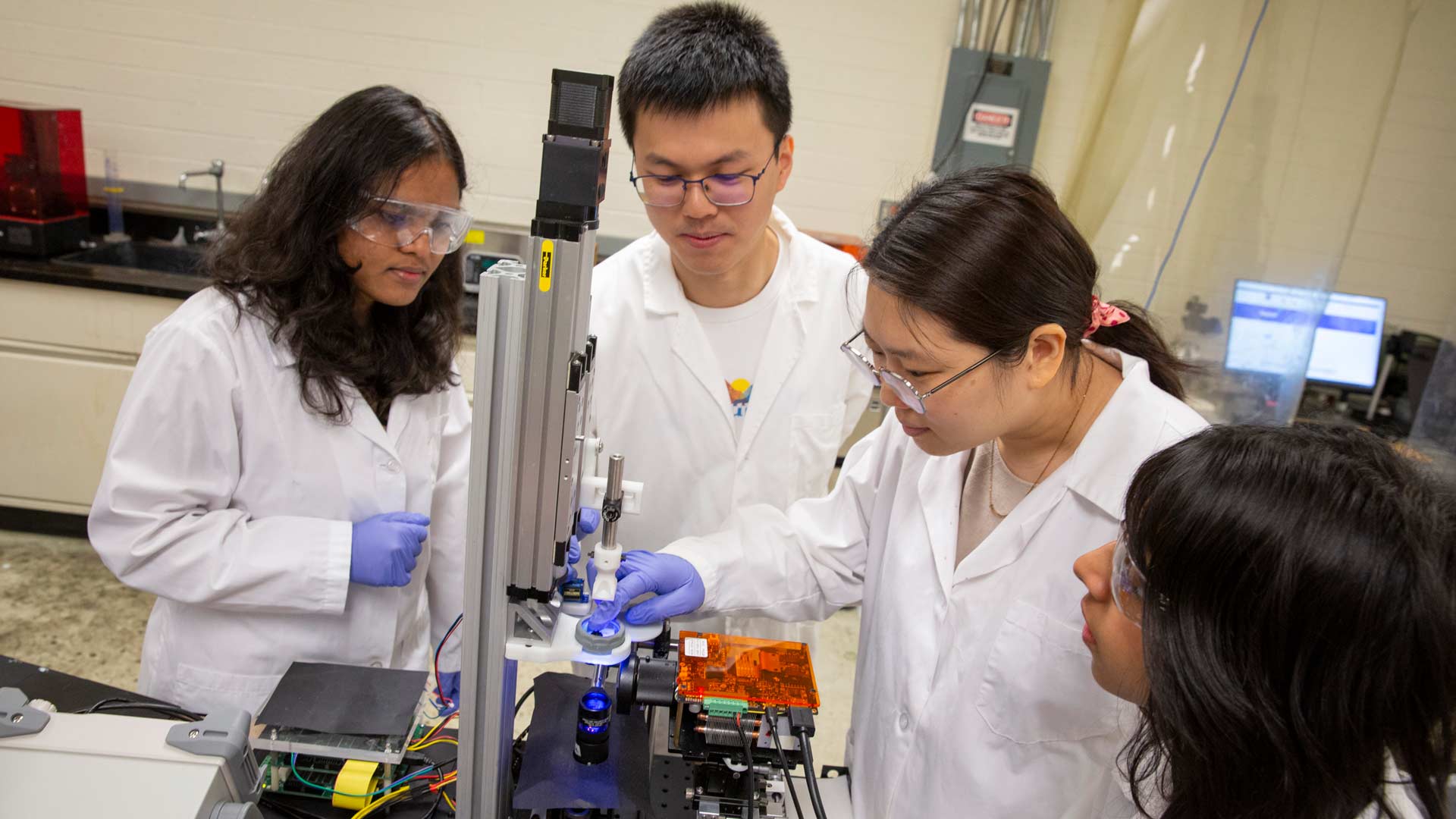

Xiangjia “Cindy” Li (second from right), an assistant professor of aerospace and mechanical engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, in her lab with three of her students. Li received a 2024 National Science Foundation Faculty Early Career Development Program (CAREER) Award for developing a novel approach to printing 3D products with complex designs using both metal and polymer materials. Photographer: Erika Gronek/ASU

Everyday products could be lighter, cheaper and last longer if the research Xiangjia “Cindy” Li is working on succeeds.

Li — an assistant professor of aerospace and mechanical engineering at the School for Engineering of Matter, Transport and Energy, part of the Ira A. Fulton Schools of Engineering at Arizona State University — earned a National Science Foundation Faculty Early Career Development Program (CAREER) Award for developing a novel approach to printing 3D objects with complex designs using both metal and polymer materials.

Her research has diverse applications, including the manufacturing of soft actuators, flexible sensors, biomedical devices and functional aerospace materials.

Li uses bioinspired design methodologies to address real-world manufacturing challenges. In other words, she draws her research inspirations from nature.

“Some living things have material structures that are multimaterial, multifunctional and hierarchical, which allows them to survive in very harsh conditions,” Li says. “The most interesting question to me is how we can replicate the functional material and hierarchical architectures that exist in nature and utilize them in the real world.”

Li applies this approach to develop complex material structures that would be very difficult to manufacture using traditional methods. For example, sea snails called limpets have the strongest teeth known to science.

“We examined a limpet tooth to figure out why it is the strongest material in nature, and we realized that it has nanofibers that are arranged parallel to the surface, which increases its mechanical performance,” Li says.

Inspired by this functional material system, she developed a magnetic field-assisted vat photopolymerization process and further designed painless microneedles for drug delivery, which was featured on the inside back cover of the Advanced Functional Materials research journal.

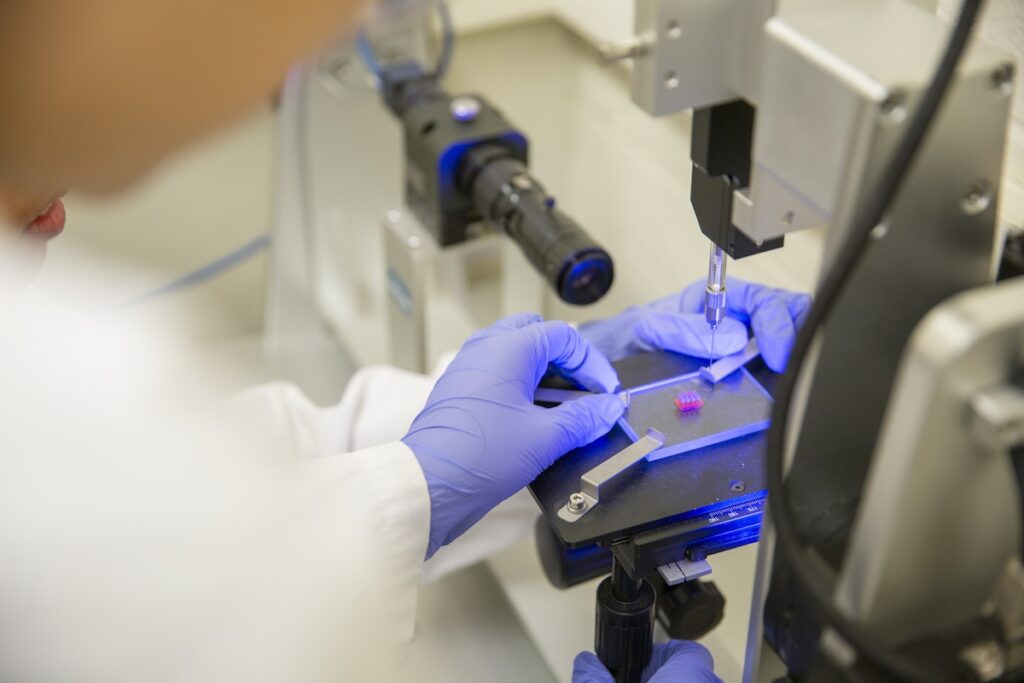

Li shows one of her students how to measure the surface energy of a 3D printed bioinspired hierarchical structure. Photographer: Erika Gronek/ASU

Li shows one of her students how to measure the surface energy of a 3D printed bioinspired hierarchical structure. Photographer: Erika Gronek/ASU

Another example, also published in the Advanced Functional Materials journal, involved developing a pioneering 4D printing technique inspired by how the Delosperma nakurense succulent’s seed covering unfolds from the compartment when exposed to rain.

These examples have laid a strong foundation for Li’s continued work in developing bioinspired manufacturing techniques, including her NSF CAREER award project to make lighter and cheaper electronic devices.

A novel multi-material printing approach

Today, engineers use microfabrication techniques such as lithography, deposition and etching to fabricate polymer objects with simple metallic structures, such as a lightweight antenna. However, these processes are high-cost, inefficient and present major constraints on design flexibility.

Li is developing an innovative, electrically assisted 3D multimaterial printing approach.

Instead of using a hybrid method where metal and polymer are fabricated separately and combined later, Li’s process will use a single process to manufacture patternable metallic structures within complex 3D polymer objects at standard room temperature.

Li was inspired by a scaly-foot snail’s unique shell structure to develop this printing approach.

Scaly-foot snails, otherwise known as scaly-foot gastropods, are commonly found more than a mile deep in the Indian Ocean. These snails live in a high-temperature, high-pressure environment.

Li asked, what about the shell’s material structure enables the scaly-foot snail to survive these harsh conditions? It turns out, the outer shell is made of metal while the inside is made of polymer. Replicating this material system and using it to manufacture everyday products was Li’s next hurdle.

“We know that polymer, metal and ceramic 3D printing exist already, but fabricating a 3D product with both metal and polymer using the same setup at room temperature is very challenging,” Li says. “We are trying to build a simple electrically assisted, multimaterial 3D printer that can print both metal and polymer using a simple process at room temperature.”

Li’s research group developed an electrical field-assisted heterogeneous material printing process called EF-HMP, which was awarded the first-place best paper award at the 2022 American Society of Mechanical Engineers Manufacturing Science and Engineering Conference.

Li’s process promises an opportunity to produce products with sophisticated designs efficiently, however, there are still challenges hindering her progress.

“We still have some fundamental science phenomena we don’t fully understand, and we want to utilize the following five years and the funds from this award to help us get a better understanding of our process,” Li says.

Li’s team can print a heterogeneous materials system with both metal and polymers, but there are a few design and material microstructuring issues left to resolve.

In the future, Li would like to expand and scale this technology so that it can be used by multiple industries, such as aerospace.

“I need to utilize other technologies in computer science such as machine learning and the digital twin to do fundamental simulations and predictions, which will allow me to have a better understanding of the process parameters to achieve smart manufacturing at a large scale,” she says.

At the end of the five-year research project, Li hopes to develop a low-cost, effective and efficient way to produce 3D devices with complex designs using both metal and polymer material architectures.

Li (first from left), receives the best paper award for developing EF-HMP. Photo courtesy of Xiangjia “Cindy” Li

Inspiring a new generation of women to pursue a career in engineering

Li has been an active member of several professional organizations working on increasing inclusivity in engineering, and she is particularly passionate about encouraging women to pursue careers in mechanical engineering.

Over the next five years, Li plans to roll out programs to educate women at ASU and beyond about her work. Li will host workshops to introduce high school students, especially girls, to the manufacturing field. She also plans to host a podcast on which she will invite renowned female engineers to provide career advice to engineering female students.

“I aim to leverage these programs to educate the public by utilizing the resources available in our lab and offering career guidance, with a particular emphasis on supporting female students, especially in engineering, hoping to help them succeed,” Li says.

“Inspiring female students to pursue an engineering career was a key factor in my decision to conduct my research at ASU,” she says. “I’ve observed a significant interest among students at ASU, particularly in the field of advanced manufacturing.”