Improving electrical efficiency

ASU researcher Wonmo Kang earned an NSF CAREER award to develop a manufacturing technique for materials with ultrahigh electrical conductivity properties

From power plants to homes and offices, devices using conductive materials form the foundation of modern society. Without materials that can conduct electricity, the world would have no lights illuminating the night, no refrigerators preserving food and no internet to communicate globally.

However, conductive materials, such as copper used in wiring, have inherent limitations that lead to an approximately 15% loss of energy during transmission.

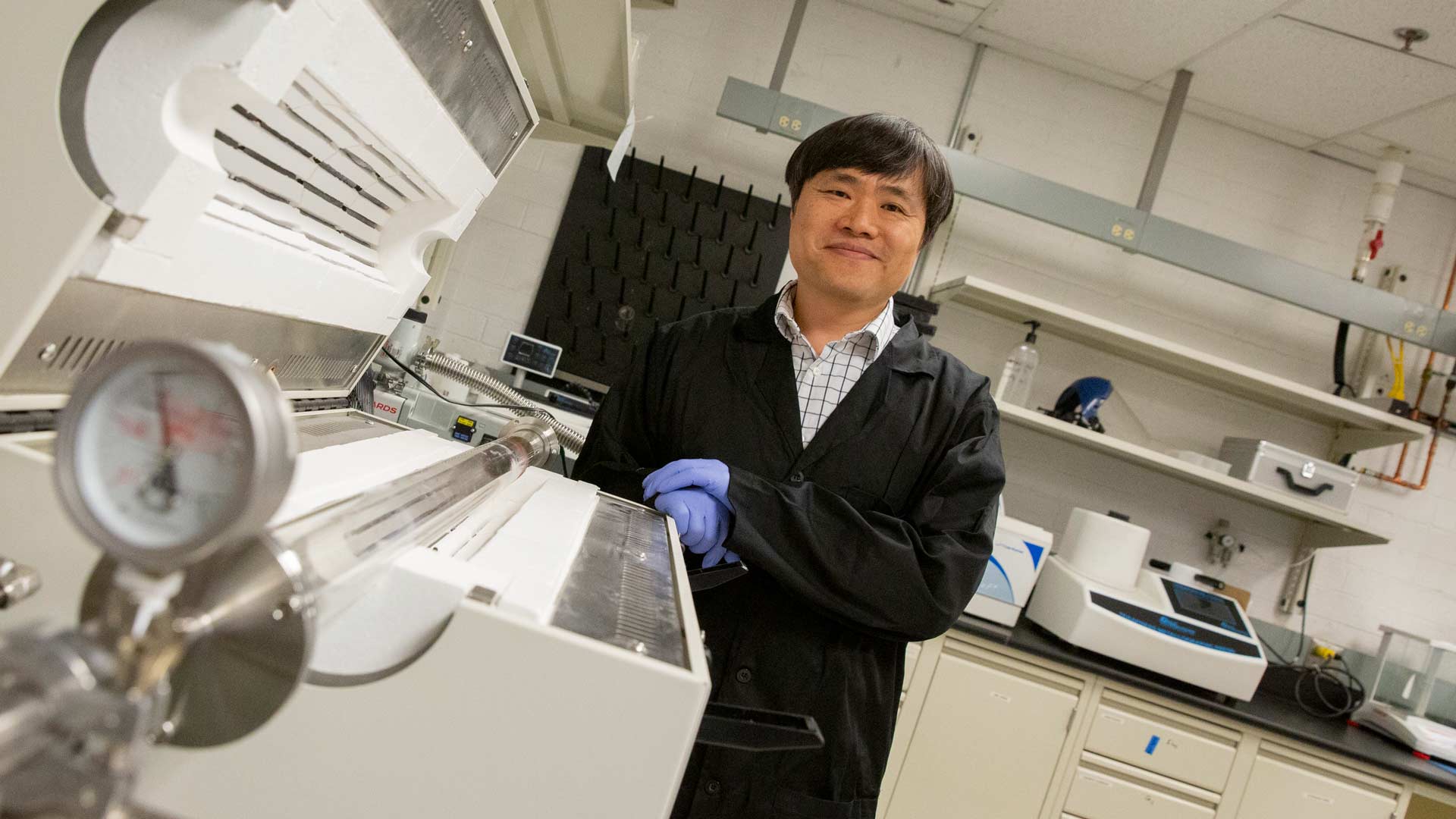

Wonmo Kang, an assistant professor of mechanical engineering at the School for Engineering of Matter, Transport and Energy, part of the Ira A. Fulton School of Engineering at Arizona State University, puts the amount of power lost into perspective.

“You might think a 15% loss isn’t much, but when you translate that to a national scale, we’re talking about 0.6 trillion kilowatts lost every year in the United States,” Kang says. “That’s significant. I’m interested in doing something about it.”

Kang earned a National Science Foundation Faculty Early Career Development Program (CAREER) Award to develop a novel manufacturing technique for materials with ultrahigh electrical conductivity properties. Ultrahigh conductor materials refer to materials with exceptionally high electrical conductivity, surpassing that of traditional conductors like pure copper. Kang aims to enhance the efficiency of electricity transmission, potentially transforming critical electricity infrastructure.

Creating a better foundation to power society

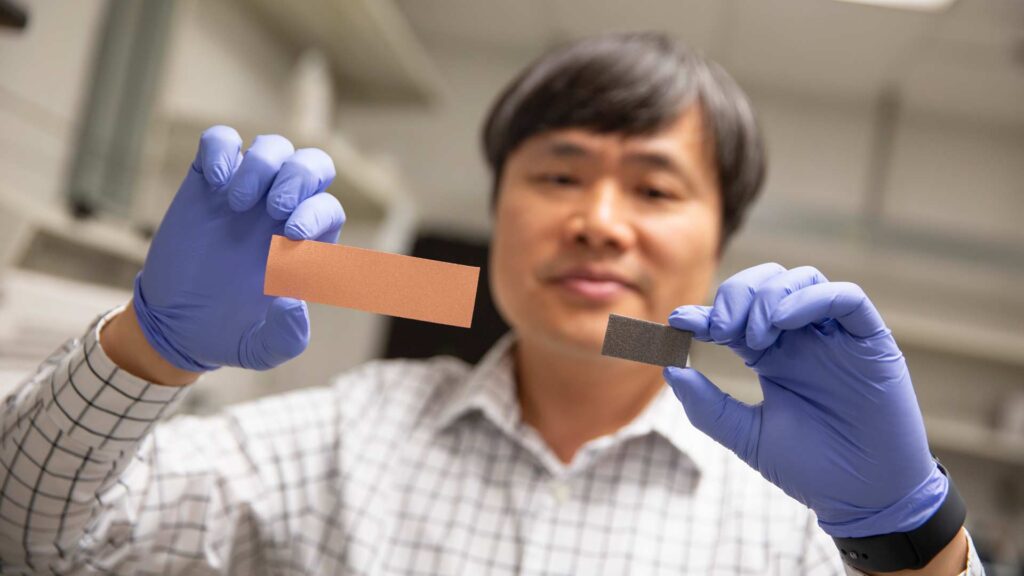

Wonmo Kang holding copper (on the left) and graphene (on the right). Photographer: Erika Gronek/ASU

Copper is the world’s most widely used conductor material, but its limited electrical conductivity causes a significant amount of energy loss through a process known as joule heating. When an electric current passes through copper, it generates heat as electrons move from one end to the other, resulting in energy dissipation.

To solve this problem, Kang set out to find alternative materials that could surpass copper’s conductivity without the prohibitive cost of options like silver. While silver conducts electricity better than copper, its high monetary value means it’s economically unfeasible for widespread electrical application use.

“Silver offers slightly better conductivity than copper, but at a high cost — nearly 100 times more expensive,” he says.

Kang’s research then pivoted to carbon composites, particularly a combination of copper and graphene.

Known as the material of the future, graphene is a two-dimensional carbon material that’s one atom thick. It stands out for its exceptional properties, including high levels of conductivity when integrated with copper, but only when the proper technique is used to combine the materials.

“Traditionally, the integration of graphene with metals has been done through aggressive mixing techniques,” Kang says. “This disrupts the continuous structure of graphene, fragmenting it into small flakes dispersed throughout the metal.”

This fragmentation impedes the flow of electrons between the metal and the scattered graphene particles when an electric current is introduced, leading to a reduction in the material’s overall electrical conductivity.

To minimize the reduction in conductivity, Kang employs a chemical vapor deposition process, which uses a series of gentle compression steps on copper and graphene. The method is designed to preserve the natural continuous structures of both materials.

“Our goal is to manufacture a composite where copper and graphene form unbroken pathways for the electrical current to flow freely, thereby optimizing electrical conductivity,” he says.

Failing forward

Kang’s innovative approach to enhancing material conductivity is a major advancement in the copper-graphene composite field.

“Our preliminary data suggests that the electrical conductivity of materials manufactured using our approach is about 41% higher than conventional methods,” he says. “This marks the highest electrical conductivity level ever recorded from a copper-graphene composite.”

Kang has successfully demonstrated the effectiveness of his approach with very small amounts of material, but he hasn’t yet figured out how to scale up the manufacturing process.

“This award will help us deepen our understanding of why this manufacturing approach outperforms others and explore how we can scale up our process to create larger ultrahigh conductor materials efficiently,” he says.

After five years, Kang aims to transition his invention from the laboratory to the marketplace with an overarching goal of improving electrical technology used by the public.

“I find this transition challenging, as my experience has been largely within academia, not industry,” he says. “I plan to seek guidance from experienced faculty to navigate this journey effectively.”

Road to clean air

Kang’s research could impact various industries, particularly the electric vehicle, or EV, sector. As the world moves towards sustainable energy solutions, the demand for EVs is skyrocketing, demonstrated by electric and hybrid vehicles accounting for more than 16% of total light-duty vehicle sales in 2023.

Kang’s work could significantly boost the efficiency and performance of electric motors, which are the heart of EVs, by enhancing the conductivity of wires connected to them. The improvement translates into real-world benefits such as extended range, reduced energy consumption and lower operational costs for EVs.

“In addition to the potential impacts on various industries, ultrahigh conductivity materials will reduce carbon emissions, contributing to substantial progress toward combating climate change,” he says.

Through the funding from the CAREER award, Kang will introduce his research to interested students through lab tours and by utilizing findings in different class activities. Lastly, Kang will support students with minority backgrounds, particularly a woman doctoral student and a Latino undergraduate student in his research group.