Mapping a new field

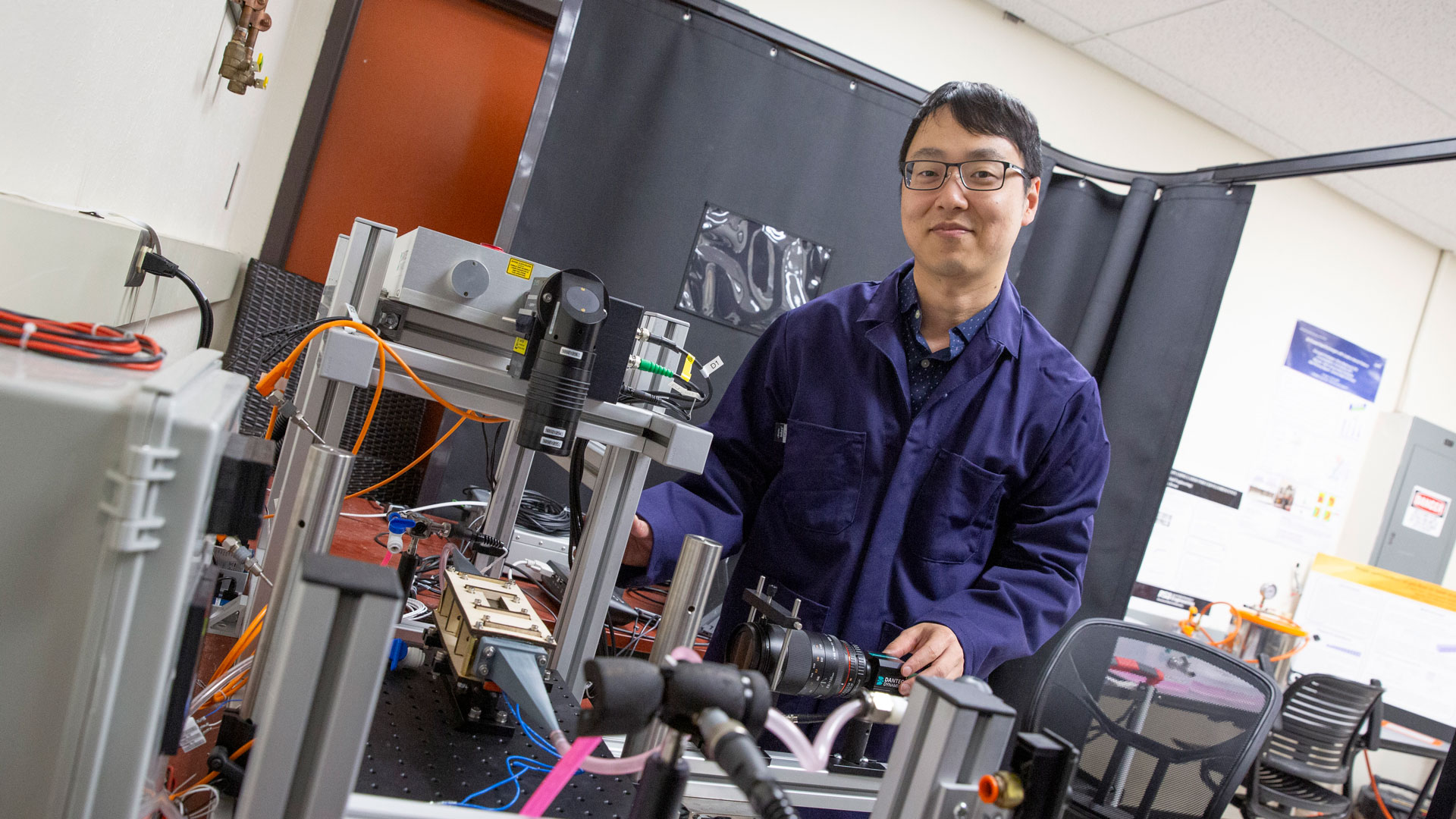

Assistant Professor Beomjin Kwon earns NSF CAREER Award for visualizing heat transfer

Many people have felt the concept of heat transfer long before they begin to understand it. When a child reaches for a cookie on the hot tray, despite their parent’s warning, they experience the sensation of a burn.

That “burn” is a result of a pressure gradient caused by the sudden and intense transfer of energy moving across the hand’s particles, known as a velocity field, that changes the structure of the fluid in contact with heat.

While much is known about heat transfer, scientists have struggled to establish methods of tracking and quantifying the geometric properties of boiling heat transfer, such as flow patterns, temperature distributions, bubble sizes and trajectories.

Beomjin Kwon, an assistant professor of mechanical and aerospace engineering for the School for Engineering of Matter, Transport and Energy, part of the Ira A. Fulton Schools of Engineering at Arizona State University, is receiving a National Science Foundation Faculty Early Career Development Program, or CAREER Award, including $540,000 over five years to develop technology that will visualize how heat transfers in boiling fluid.

“Understanding temperature distributions and driving processes is crucial for developing next-generation thermal management systems,” Kwon says.

Filling in for unknown variables

Current methods in heat mapping can determine heat transfer at specific points and gauge temperature, but cannot produce accurate, larger-scale maps due to high amounts of corrupted and distorted data, known as noise.

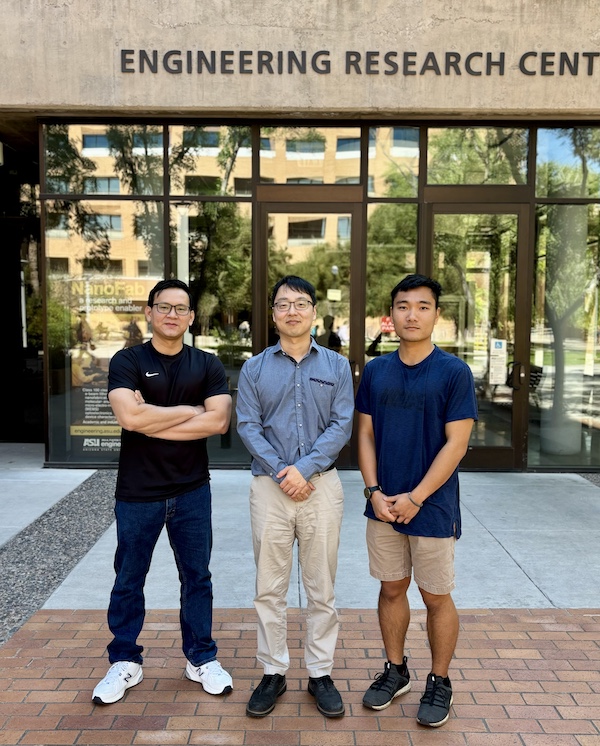

Mechanical engineering doctoral candidates Nam Nguyen (left) and Nagahiro Ohashi (right) stand outside their laboratory with their principal investigator, Fulton Schools Assistant Professor Beomjin Kwon (center). Photo courtesy of Beomjin Kwon

To combat this, Kwon is developing a technology with help from artificial intelligence, or AI, to map a temperature field and track the transfer of heat across a system with a level of precision previously thought impossible.

“There are no computational methods to deal with data noise when mapping temperature fields in dynamic fluid, making the information we can obtain from experiments incomplete,” Kwon says. “But now, we have advancements in AI.”

To infer data from that noise, the team is integrating AI and layers of machine learning networks, known as deep learning, to simulate complex decision-making power similar to that of a human brain.

Nagahiro Ohashi, an aerospace engineering doctoral student in Kwon’s lab, says that using AI to fill in the data gaps caused by noise will clear up a lot of uncertainties.

“Given the constraints on the amount of information you have, you need to be able to infer the rest of these fluid characteristics to analyze the entire system,” Ohashi says. “We are crafting a way to visualize the velocity fields given a limited amount of temperature information.”

Mapping the way

The ability to infer previously inaccessible data points has allowed Kwon to develop software that can generate a map depicting the flow of energy in a fluid.

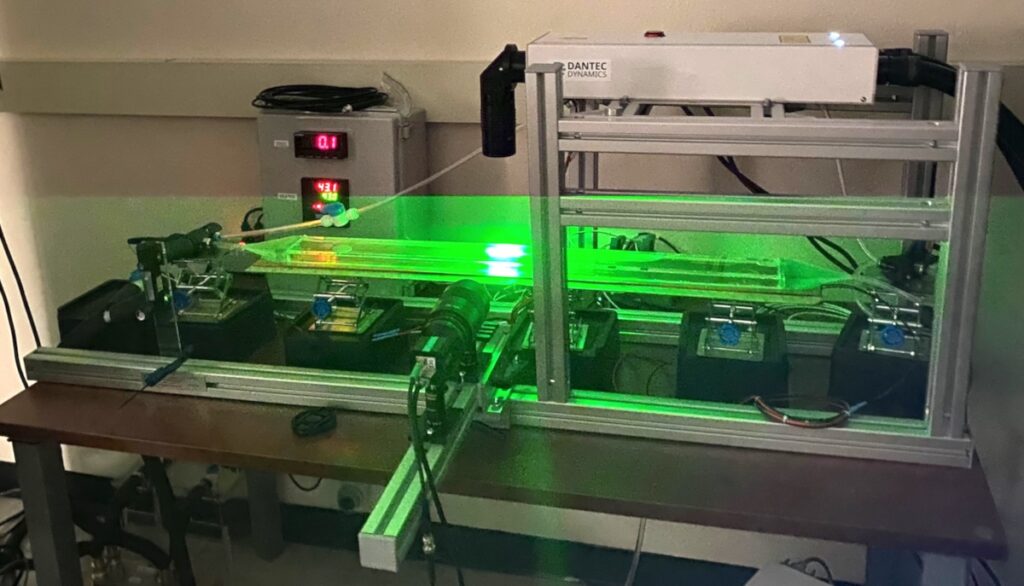

The apparatus involves the circulation of dyed fluid into a chamber containing heated protrusions on its floor, while data is captured by a high-frequency laser and camera.

Nam Nguyen, a mechanical engineering doctoral candidate in Kwon’s lab, incorporated additive manufacturing while designing the chamber’s floor to optimize the protrusions for observation.

“Our group is one of the first to use this technique to visualize the flow site like this,” Nguyen says, “and we’ve optimized it.”

The CAREER award funding equips Kwon with the resources he needs to sustain his team and generate new outreach opportunities. His lab is also starting a YouTube channel to promote accessible education and establish alternative resources for students.

“The younger generation has grown accustomed to watching videos online to solve questions and get information,” he says.

Kwon notes that the visual nature of the research lends to a visual medium and hopes the new platform can make learning the material more intuitive for general audiences.

The apparatus involves the circulation of dyed fluid into a chamber containing heated protrusions on its floor, while data is captured by a high-frequency laser and camera. Photo courtesy of Beomjin Kwon

Industry Implications

Mapping the driving processes of heat transfer has vast implications for sustainable industrial applications. From aviation to health care, a majority of daily appliances rely on heat transfer and fluid dynamics.

“To improve the design of the devices we use daily, we need to know how the temperature field is created,” Kwon says. “Having a visualization technique will help identify how we need to modify the design.”

Kwon says his method has the potential to support more sustainable and high-performing microchips, which use water for cooling and could inspire the development of novel fluids. He predicts that the future direction for cooling electronics will be submerging hot microchips within a cooling fluid that can potentially repurpose the generated heat.

“We hope to pave the path for more effective and cheaper visualization methods as well as cooling solutions,” Kwon says. “Looking forward, we want to make this technology affordable for both researchers and companies so they can take it even further.”