The circle of solar panel life

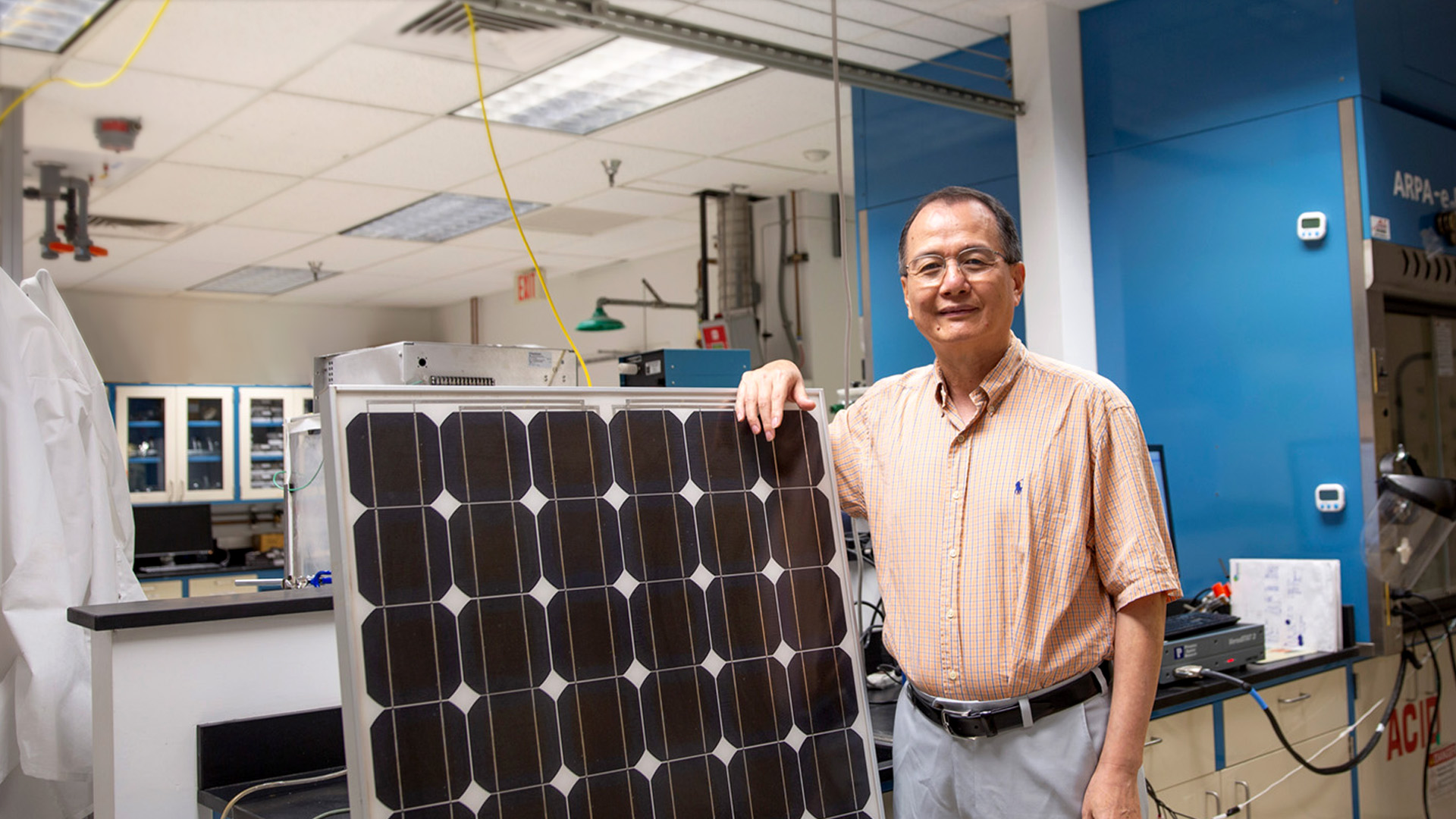

ASU researcher Meng Tao and his collaborators aim to improve solar panel design to increase material recovery during recycling

With climate change becoming an increasingly dire problem, solar, or photovoltaic, power generation can help to remedy the problem as a zero-emission source of electricity. Despite providing green energy, solar panels aren’t without their environmental drawbacks: They’re difficult and expensive to recycle.

“For the last 40 years, the focus has been on solar panel efficiency, cost and reliability,” says Meng Tao, a professor of electrical engineering in the Ira A. Fulton Schools of Engineering at Arizona State University. “I was one of the pioneers who said, ‘We need recycling technologies.’”

After a panel’s life expectancy, which ranges from about 25 to 30 years, is reached and the panel is no longer useful, it’s typically added to the large amounts of trash that go into landfills and incinerators every year. As solar technology use continues to increase, the International Renewable Energy Agency estimates that by the 2050s, end-of-life solar panels will result in 5.5 to 6 million metric tons of waste per year.

Tao, a faculty member in the School of Electrical, Computer and Energy Engineering, part of the Fulton Schools, set out to enhance economical circularity — the reusability of products and their base materials — by recycling them. While his efforts thus far have focused on recycling methods for existing panel designs, he found limitations to how much of the material recycled from existing solar panels can be.

Tao then decided to increase panel circularity by collaborating with experts in a variety of areas. The result was five recommended changes to panel designs that will make them easier and more cost-efficient to recycle that are detailed in a paper in the One Earth scientific journal.

A circular economy that manufactures sustainability

Among the recommendations Tao suggests is to eliminate lead from solar panels. The toxic metal is part of an alloy, or combination of metals, used with tin in the solder that connects solar panels’ conductive pieces together.

Current recycling techniques are uneconomical for lead recovery, costing about 100 times the value of the salvaged metal. Tao and his collaborators recommend replacing the solder with a lead-free alternative.

Along with lead, he sets his sights on replacing a more valuable metal found in solar panels: silver. Over time, solar panel producers have reduced their panels’ silver content to save on manufacturing costs. The silver in a panel is now low enough that recovery costs more than the material is worth.

So instead of using silver, Tao and his colleagues recommend using copper, which is already incorporated in solar panel parts, to reduce manufacturing costs and eliminate the need for silver recycling.

While there are technical challenges to overcome due to chemical reactions such as oxidation and interactions between copper and solar panels’ silicon cells, Tao consulted collaborator Thad Druffel, a researcher and expert in solar technology at the University of Louisville, to confirm the idea as worthy of exploration.

Replacing current materials for successful solar recycling

Adding to the difficulty of solar panel recycling is encapsulant, a compound used as a glue to stick solar panels’ glass casing to the silicon cells that convert light into electricity.

“You’ll want encapsulant to be stable under UV radiation, hot and cold temperatures, day and night, in moisture and all kinds of weather conditions,” he says. “But when it comes to end of life, you want an encapsulant that is very easy to degrade or destroy. It’s two opposite requirements.”

Tao recommends the use of a new encapsulant that can firmly hold panels together but detach easily when exposed to certain conditions, such as chemicals or heat, during the recycling process.

For accuracy and expertise in recommendations for new encapsulant materials, he consulted Kim McLoughlin, a principal engineer with chemical company Braskem.

A related problem to encapsulants is modern dual-glass panel designs. Dual-glass solar panels use glass to cover the front and back of a panel and are more rigid than older designs, which use a softer material known as a fluoropolymer, to cover the back.

While dual-glass panels are more durable and have higher power output than a traditional module, current technology can’t separate the glass from both sides of the panels. The result is that no metals in the cells can be recovered, and the glass will have to be recycled into lower quality raw material such as concrete aggregate or sandblasting.

Tao worked with Paul W. Leu, a University of Pittsburgh industrial engineering professor and B.P. Faculty Fellow, to develop ideas to make delamination between silicon and glass easier, such as a new encapsulant material.

Tao and his colleagues see even better sustainability potential for dual-glass modules if a recycling method can be developed for them: Fluoropolymers aren’t recyclable, meaning less material would need to be trashed for good when recycling dual-glass panels.

New ID system gives solar panels new life

Last on the list of recommendations is creating a system that can trace and identify solar panels for up to 25 years. Because different kinds of solar panels use distinct materials and designs, recycling methods that work well for one kind of panel may not perform as well for another.

After a solar panel’s life is spent being exposed to the elements, labels showing model numbers and specifications are often faded enough to be unidentifiable. The information on the labels is also limited and not provided in a consistent format. Recyclers can make only educated guesses as to the best ways to break the panels down into their components, resulting in wasted material if the wrong method is chosen based on appearance alone.

The current ID and label system can also present a problem when attempting to extend the life of an individual panel. When an older solar power generation system is replaced, some panels may still work for other systems. However, without being able to determine if a functional used panel has the proper specifications, it’s useless.

Tao and his colleagues suggest a new traceability system, featuring durable Smart Tags, which would consist of technology such as barcodes, QR codes and radio frequency identification tags, with industry standard unique IDs mapped to data to reveal make, model, constituent materials and electrical properties such as wattage. The system would work similarly to how digits in vehicle identification numbers on cars and trucks correspond to mechanical and cosmetic specifications.

Tao turned to Alicia Farag, co-founder and president at Locusview, a company that makes construction management and asset traceability software to create a digital thread from manufacturer to end user. Farag has expertise in standardized IDs for industries and consulted on the One Earth paper.

Additionally, Farag is working with Tao and Dwarak Ravikumar, a Fulton Schools assistant professor of civil, environmental and sustainable engineering and an expert in the circular economy and sustainability of photovoltaic systems, to develop such a solar panel ID system.

“Professor Meng Tao is a true expert, and it has been very insightful to combine his deep knowledge of solar panel design with our knowledge of asset tracking and traceability to provide a novel and innovative solution to solar panel traceability for reuse and recycling,” Farag says.

Tao and Ravikumar, a faculty member in the School of Sustainable Engineering and the Built Environment, part of the Fulton Schools, have a history of collaboration. Tao was on the committee for Ravikumar’s doctoral dissertation on improving solar panel circularity, and they have co-authored and published scientific studies on improving the sustainability of photovoltaic systems.

“The solar panel itself is good for the environment,” Ravikumar says. “But we have to understand that it still requires a lot of raw materials and energy to manufacture solar panels.”

He says much of solar panel manufacturing happens in regions heavy on fossil fuel use such as China, making it essential to use the panels for as long as possible and recover a maximum amount of material from end-of-life panels.

With so many recommendations for solar panel design and recycling to explore, Tao encourages students to assist in his research in the field. Students of all levels — from those studying for undergraduate to doctoral degrees — who are passionate about sustainability and the environment are eligible to apply. Interested students majoring in electrical engineering, chemistry, chemical engineering or materials science can contact Tao at [email protected].