Mirror, mirror: ASU researcher’s synthesis and analysis of 2D Janus materials lights the way to a quantum future

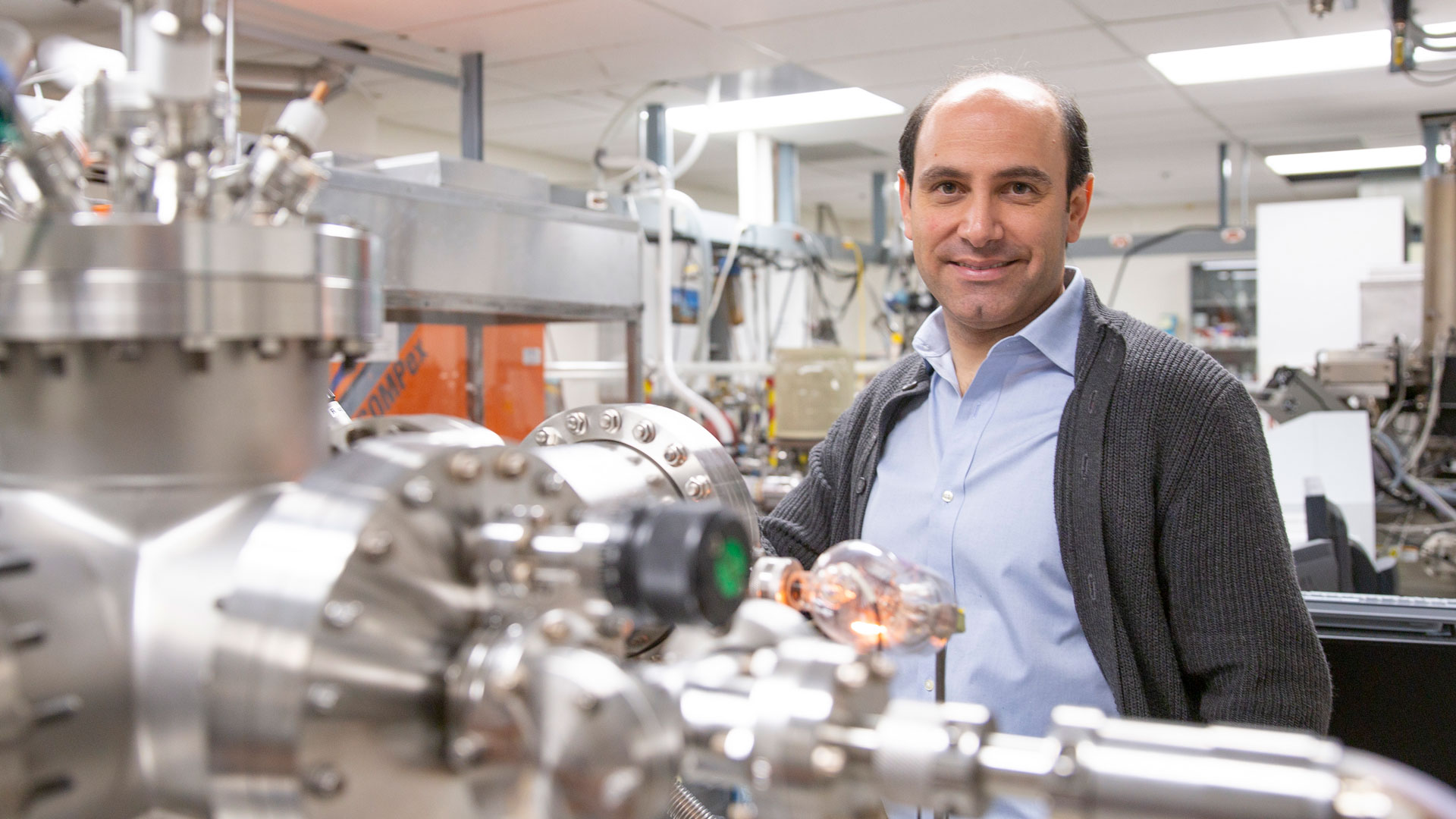

Above: Arizona State University Associate Professor Sefaattin Tongay is leading research to demonstrate consistent, high-quality fabrication techniques for 2D Janus materials and explore their potential for quantum technologies. This photo was taken before the current pandemic social distancing and face-covering requirements went into effect. Photographer: Erika Gronek/ASU

Compared to the first silicon-based transistors of the 1950s, the extraordinary capabilities of today’s consumer electronics seem like the stuff of science fiction. But new research at Arizona State University is developing the foundation of quantum-based technologies that could transform our reality beyond what we’ve imagined.

Sefaattin Tongay, an associate professor of materials science and engineering in the Ira A. Fulton Schools of Engineering at ASU, is leading one of the first research teams to demonstrate new, high-quality manufacturing techniques for a unique type of 2D substance called Janus materials.

“We are coming up with an entirely new chemistry of Janus materials that has never been reported before. And with the manufacturing technique [we are developing], we are able to get high-quality Janus layers for completely new types of light-emitting materials and entirely new quantum domains that have never been explored before,” says Tongay, who is also the materials science and engineering undergraduate program chair in the School for Engineering of Matter, Transport and Energy, one of the six Fulton Schools.

“No one has stepped into this unknown territory,” he says.

Tongay’s research will set the foundation for new information technologies, efficient energy generation and energy storage based on hydrogen and other applications.

Tiny materials for big advances

Conventional 2D materials, which Tongay also researches, often use a few layers of atoms that are less than 1 nanometer thick. These extremely thin materials are able to generate properties that 3D materials cannot. Janus materials, a subcategory of 2D materials, have exciting potential for future advances in quantum computing.

Unlike conventional 2D materials, 2D Janus materials have two faces that can be made of different substances. Their name comes from the Roman god Janus, who represents transitions with his two faces that look to the past and future.

A key component in harnessing the capabilities of 2D Janus materials is the introduction of mirrors. Tongay’s team is creating a two-faced Janus material that has different atoms on each side, such as selenium on one face and sulfur on the other face. That very thin material is then covered on each side by two nanoscale layers of a mirror-like material called a Bragg reflector. Light is introduced between the mirrors and cannot escape. As the light particles, called photons, bounce between these layers of mirrors, they become more concentrated.

“When the photon density is so high, the materials start to behave differently,” Tongay says. “In this project, we aim to understand how these materials behave at this state and transition to a new generation in quantum technology.”

At this high photon density, the material becomes a “quantum emitter,” shooting a very strong beam of light at a particular wavelength on the color spectrum. These beams are called bosonic lasers and they are “super tiny, super sharp and very efficient,” Tongay says.

Bosonic lasers can be used to make quantum information devices that use light to transmit information. The resulting material can also be used for very efficient solar cells or to create spintronic devices, which use the magnetic spin of electrons to drive electronics.

New fabrication method propels progress

Over the past four years, Tongay and his research team have transitioned this field of study from theoretical to practical by fabricating these experimental materials.

“We have innovated new ways to make these materials in good quality on a large scale in a controllable way,” Tongay says. “I’m proud to say that my team is one of the leaders in the Janus field.”

Ying Qin, who recently graduated from ASU with her doctorate in materials science and engineering and continues to work in the Tongay Lab as a postdoctoral scholar, has played an important role in the research team’s efforts to synthesize Janus materials.

The class of base material used to generate the 2D Janus material — called transition metal dichalcogenide monolayers, of which molybdenum diselenide is an example — have previously been synthesized relatively easily. Creating alloys of different chalcogens — a group of elements including oxygen, sulfur, selenium and tellurium — randomly distributed in the material matrix has been well established by other researchers.

The novel approach Tongay, Qin and their international team of collaborators have developed involves the much more difficult task of controlling this process to edit the base structure to show two distinct layers that each contains a single type of chalcogen atom.

“We developed a room temperature method with a reactive hydrogen plasma. We pass hydrogen gas through a tube in which we have our monolayer [of molybdenum diselenide], and pass an electric field to ignite the hydrogen into plasma form,” Qin says.

In just eight minutes, a series of reactions occurs on the materials in the tube. These reactions allow selective etching of the top layer of selenium in the structure. The material then reacts with sulfur and transforms into a Janus structure with sulfur on the top and selenium at the bottom of the molybdenum layer.

“It is very exciting,” Qin says. “The Janus structure has been predicted to have a lot of interesting properties, but the difficulty of fabricating it made it hard to confirm whether they’re detectable.”

This underlying fabrication process is now being combined with the addition of Bragg reflector mirror layers to explore this 2D Janus material’s quantum properties.

Innovation draws recognition

Tongay’s work to synthesize, understand and find quantum applications using these 2D Janus materials has been funded by a number of government agencies.

“The novelty is quite apparent, the merit is high and the program managers and federal agencies recognize our abilities and world leadership in this particular field,” Tongay says.

A U.S. Department of Energy grant supports the work dedicated to the synthesis and discovery of 2D Janus layers and understanding their fundamental optical properties.

One grant from the National Science Foundation, or NSF, is funding the development of instrumentation to enable the synthesis of those layers. Earlier this year, another NSF project began to create completely new and high-performance transistors and spintronic devices that use the natural spin of electrons enabled by 2D Janus layers.

Starting in June, a project funded by a $557,000 grant from the NSF’s Division of Materials will explore Bose-Einstein condensation — a state of matter that occurs at very low temperatures — in Janus layers.

“With these projects, we are going to be able to fill the knowledge gap in how to make these materials, how to improve the quality of the materials and understand the optical and excitonic properties of the materials,” he says. “With this knowledge, we will mark unique applications in quantum information, spintronics, spin-transistors and Bose lasers. While doing so, we will step into this unknown quantum territory, which is quite fascinating.”

Making materials science matter to young minds

Material is a vague word. It could refer to fabric or the background notes used to prepare a report. One could even make a connection to the negative connotation of materialism or recall the lyrics of Madonna’s famous song “Material Girl.”

Most people, however, do not think of materials science and engineering — an important field of study that affects nearly everything people come into contact with each day.

Arizona State University Associate Professor Sefaattin Tongay is trying to bring the wide world of materials science and engineering to students’ minds with a new outreach program, called Living in a Materials World.

Through monthly and quarterly events, held virtually and in-person when it’s safe to do so, Tongay wants to make the subject exciting for the next generation of materials scientists and engineers.

Tongay will hold events with local high school and middle school students to demonstrate highly advanced microscopy techniques and other materials science and engineering activities happening at ASU and in the wider materials community.

In other activities, he will take common items associated with different seasons of the year — such as 4th of July fireworks in summer or holiday lights in winter — and examine the materials that make them work.

“As we look at these devices from the macro to micro to sub-micro levels, I want to show students what those materials are, the necessity of materials development and how other engineering disciplines heavily rely on materials science,” Tongay says.

Ying Qin, a recent doctoral graduate from ASU now working in Tongay’s lab as a postdoctoral scholar, says all the properties of things engineers work with are determined by the materials that make them.

“Materials science gives you an advantage of understanding why everything is happening the way it is,” Qin says.

It is this wide-reaching influence that makes materials science and engineering so important.

“I want to show how the little innovations you make have enormous impacts on the whole field,” Tongay says. “If you want to make an impact, this is the place to be.”