Modernizing military preparedness

Fulton Schools faculty collaborate on multi-university project to help provide highly trained tech workforce for U.S. defense industries

Strong national defense increasingly demands staying at the forefront of technological innovation. Meeting the challenge requires cultivating the ingenuity to envision and achieve advances in myriad areas of science and engineering.

That step, however, is only the foundation for equipping today’s military forces with the tools to overcome threats posed by adversaries that may be deploying similarly advanced technologies.

The key to maintaining an advantage is having the resources and infrastructure to develop, manufacture and sustain the complex high-tech systems required to ensure effective protection against formidable opponents.

“What we need at the ground level is a robust ecosystem geared toward inspiring and equipping individuals with the knowledge and skills required to efficiently manufacture the hardware necessary to modernize our military,” says Ehsan Dehghan-Niri, an associate professor of manufacturing engineering in the School of Manufacturing Systems and Networks, part of the Ira A. Fulton Schools of Engineering at Arizona State University.

Opening career paths for future STEM experts

Dehghan-Niri and several colleagues are beginning work with several colleagues to overcome manufacturing workforce inadequacies. He was recently awarded a $3.5 million U.S. Department of Defense grant to lead efforts to construct a manufacturing workforce development pipeline.

That pipeline will be designed to provide a flexible and sustainable supply of workers trained for roles to help the country’s military forces prepared to engage in future international conflict scenarios.

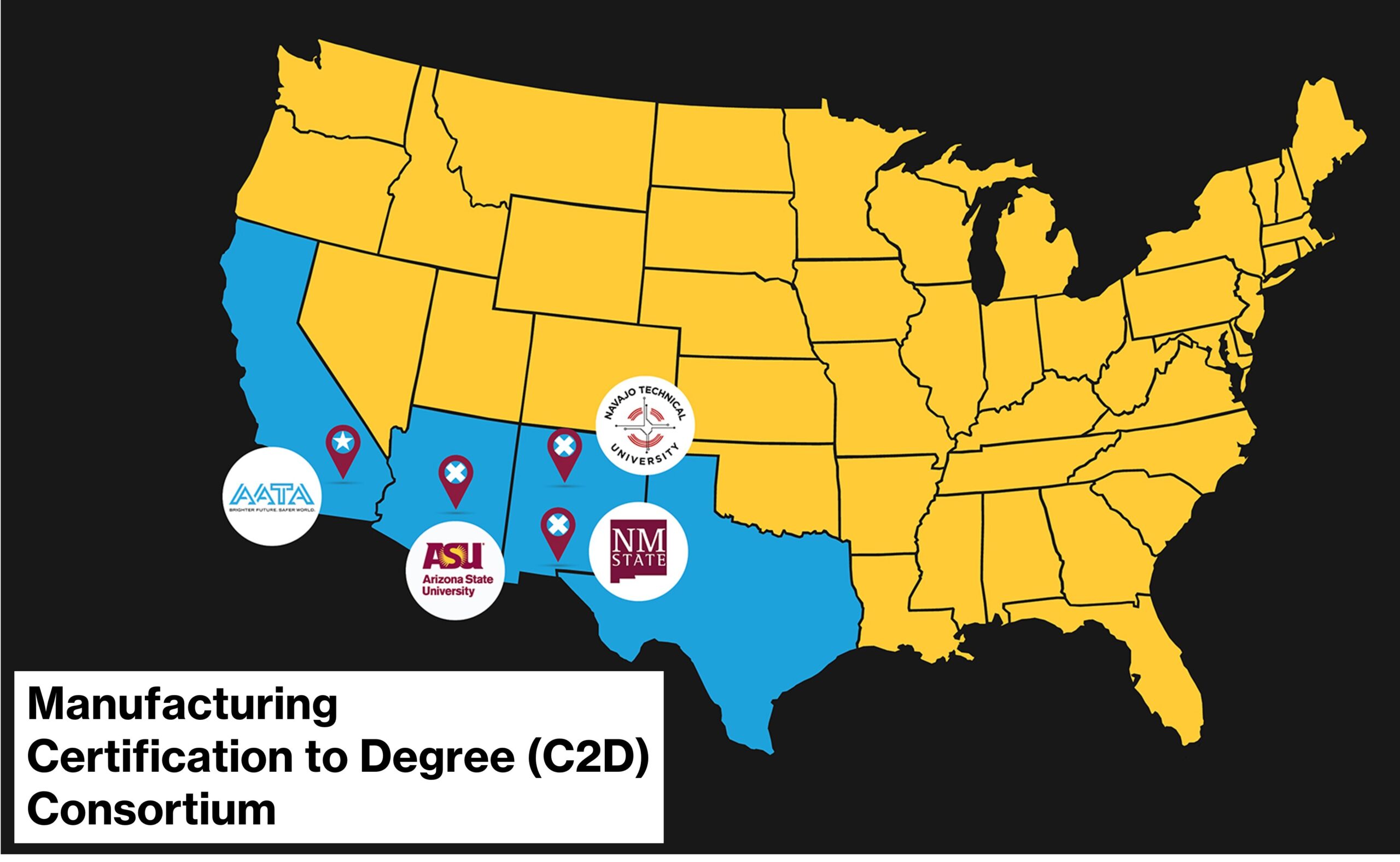

ASU faculty members will join collaborators at New Mexico State University, Navajo Technical University and the American Aerospace Technical Academy on the project, with Dehghan-Niri directing work to create a manufacturing-focused Certification to Degree, or C2D, Consortium designed to equip students with skills through hybrid certification programs that will open paths for them to earn science, technology, engineering and math, or STEM, certifications or degrees with a focus on manufacturing.

Dehghan-Niri says his industrial background at General Electric, combined with six years of academic and workforce development experience, has led him to the conviction that many STEM programs in the U.S. operate in reverse order of ideal career development. He says students enroll in these programs without acquiring a thorough understanding of potential future employment opportunities.

Frequently, these students change majors after studying for several years or graduate with no interest in their chosen field. Upon joining the workforce, the new graduates’ employers commonly require them to undergo training or certification during the early years of their employment, adding supplementary educational costs for employers.

“The C2D’s innovative approach endeavors to invert this process. Early integration of hands-on, skill-oriented methodologies, coupled with industry collaboration, is crucial to STEM programs, particularly in the manufacturing domain, to foster deeper engagement among students and introduce them to potential manufacturing career pathways,” Dehgan-Niri says.

The new Certification to Degree Consortium program, or C2D, team is led by a diverse and experienced team of researchers, educators, business leaders, laboratory directors, academic leaders and manufacturing systems experts. They will collaborate on multiple long-term efforts to develop and train the future workforce to support U.S. defense industries. Photo composite courtesy of Ehsan Dehghan-Niri/ASU

Building skills to advance national security efforts

“To better position the current and next-generation manufacturing workforce to produce military systems and components, the two main gaps in the manufacturing workforce and the gap in certain skills must be addressed efficiently and simultaneously,” says Dehghan-Biri.

The project team will develop two hybrid certification programs to teach advanced manufacturing and nondestructive testing — a set of inspection techniques and methods used in many industries to evaluate the integrity, quality, and properties of materials, components or structures without causing any damage or altering their physical properties, which is one of Dehghan-Niri’s areas of expertise. In addition, the team will design and develop customized cyber-learning tools to use in efficiently teaching students.

Both certification programs’ cyber-learning components will include online learning and the use of a shared C2D digital laboratory using virtual reality, or VR, modules for early exposure to simulation training. The digital laboratory offers students safe and efficient simulated hands-on experience, enabling them to gain familiarity with expensive and potentially hazardous manufacturing equipment virtually before undergoing practical training.

“The modular aspects of our digital laboratory will enable us to create a digital factory or digital twin in the future to serve different industries and manufacturing processes,” Dehghan-Niri’s says. “The certification programs will not replace necessary physical hands-on training, but rather enhance it by providing a cost-effective and efficient way to prepare students for training on real equipment in a shorter period.”

He says retention rates in STEM academic programs is relatively low compared to programs in other academic areas, and he is confident that the C2D concept could help increase student retention.

Career opportunities for military veterans and underserved communities

The project aims to help two groups increase their potential to supply defense industry with an expanding source of trained workers — military veterans and students from underrepresented communities.

Demographics show both of these groups are untapped populations that, with support, could help the manufacturing industry build a larger and better trained workforce for the future.

“Our service members have served our nation bravely on the battlefield and in challenging military conditions,” Dehghan-Niri says. “Now with their discipline, dedication and organization skills, coupled with trust, they are ready to continue their service to the country in the manufacturing sector, where their commitment and abilities will once again play a vital role in safeguarding our nation.”

The consortium will be unique in its regional impact on minority students as it integrates two Hispanic Serving Institutions, ASU and NMSU, as well as tribal colleges and universities like NTU, in a cross-disciplinary partnership. In addition to these three academic partners, the AATA, a well-established nonprofit training institute with experience in supporting veterans in the fields of nondestructive testing and manufacturing training and certification, will help to establish the consortium.

Deghgan-Niri says there’s a critical need for fast-track workforce development programs to support U.S. national defense interests around the world.

“We won’t be able to obtain the components and systems needed to manufacture new ships, aircraft and tanks unless we have a stream of technicians and students well-versed in emerging technologies transitioning quickly from the classroom to the workforce,” he says.

Binil Starly, professor of manufacturing engineering and director of the School of Manufacturing Systems and Networks, says growing a larger source of skilled job candidates for companies that are supplying the U.S. government with advanced technology is nothing less than essential to the nation’s future. says

“I see this project eventually helping to strengthen the foundations of the country’s freedom and prosperity,” says Starly, whose expertise includes advanced manufacturing processes, cybermanufacturing, digital factories, robotics and industrial automation.

Starly says the program will present an opportunity for diverse segments of the population to come together in educational and career pursuits for a common purpose, which can set the stage for fostering social cohesion across communities that still remain somewhat disparate.

Dehghan-Niri and Starly also aim for the project to pinpoint solutions to some of the prevalent shortcomings of technology education and industry workforce development practices.

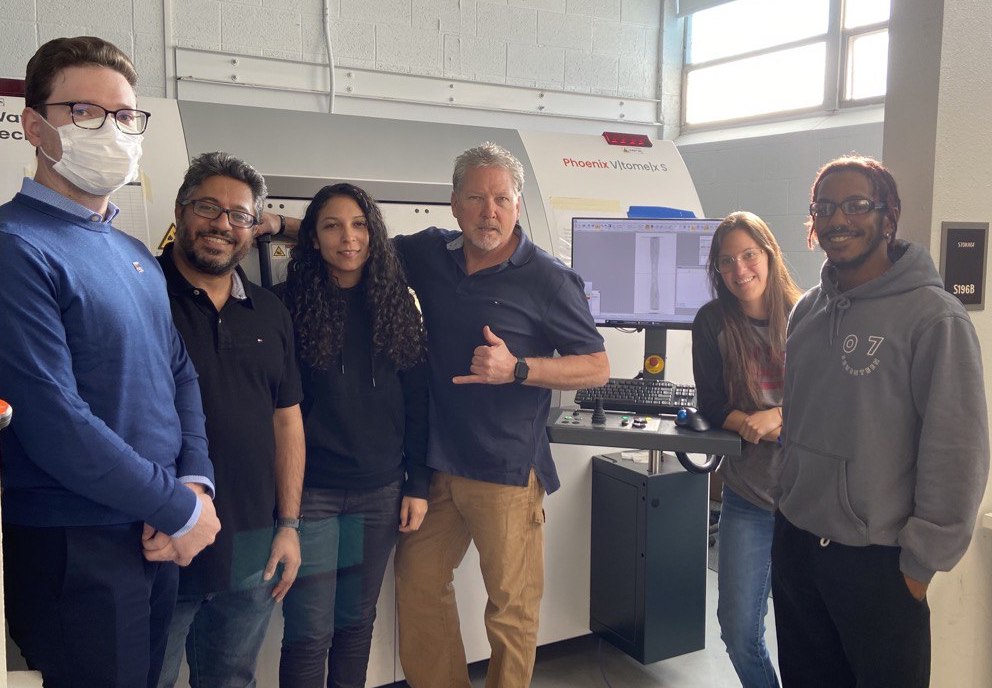

Fulton Schools Associate Professor Ehsan Dehghan-Niri, second from left, poses in the Intelligent Structreus and Nondestructive Evaluation Laboratory at New Mexico State University, where he provided hands-on training to students and tech industry workers on how to use of the lab’s advanced manufacturing-related technology — including a computed tomography, or CT, scanner supplied by the U.S. Department of Defense. Pictured are is NMSU Associate Professor Borys Drach (to Dehghan-Niri’s left) tech industry workers Patty Castillo and Brad Stewart, a U.S. military veteran, and NMSU graduate students Veronica Gurrola and Darin McFadden. Photo courtesy of Ehsan Dehghan-Niri/ASU

Tailoring manufacturing education for adaption

The formal outline and description of the manufacturing C2D Consortium and its main objectives details some of the obstacles the collaborative endeavor seeks to overcome.

One major problem the description notes is that many conventional STEM academic programs lack a clear and concise focus and are not easily adaptable to changing and evolving skill sets required by industry.

Another problem noted is that many many STEM degree programs don’t adequately address the major challenges faced by the manufacturing industry. In addition, students who enroll in these programs lack an adequate understanding of potential future employment opportunities.

To help remedy such problems, in addition to the program’s emphasis on accessible cyberlearning and hands-on experience, students will also have opportunities to develop skills through industry collaborations and an introduction to standard practices and innovation in areas such nondestructive testing, robotics, automation and additive manufacturing. They will also receive information about the array of varied career pathways that are expanding with the manufacturing world.

Giving workers valuable roles in defending the nation

Collaborators at the project’s partner institutions are optimistic about the value and potential impacts of the program.

“The C2D program will provide veterans opportunities to utilize skills they obtained while serving their country,” says retired Brigadier General Eric Sanchez and director of the Physical Science Laboratory at NMSU. “The additional skill training they will receive increases their marketability in a field with a high demand both in the defense industry and civilian industries. I believe this is a win-win situation for the veterans as well as future employers.”

Borys Drach, an associate professor of mechanical engineering at NMSU, says C2D will porvide a boost toregional workforce development efforts.

“The new certification programs will significantly enhance workforce development in the Southwest region,” Drach says. “Focusing on the vital and rapidly developing sectors of additive manufacturing and quality control, they will offer a powerful opportunity for our local students and veterans, many of whom come from underserved backgrounds.”

He says the educational programs will be designed with input from leading industry experts to make students highly competitive in today’s job market, setting them on a path to rewarding and well-compensated careers.

“I am excited about the new opportunities that the C2D Consortium will unlock for our regional community,” Drach says.

The program’s virtual reality training initiative is a potentially transformative approach to enhancing the training of non-destructive testing technicians, says John Stewart, a military veteran and the founder and director of the AATA.

“This initiative aims to investigate the effectiveness of virtual reality training compared to traditional classroom training and its impact on the on-the-job training phase, with the ultimate goal of potentially recognizing virtual reality hours as valid on-the-job hours,” Stewart says.

“The training initiative represents an innovative approach to NDT technician training. By comparing the outcomes of VR-enhanced training with traditional methods and involving employers in the evaluation process, there’s strong potential for significant benefits in terms of cost savings and more skilled technicians, should the VR training prove successful,” Stewart says.

Scott Halliday, director of the Center for Advanced Manufacturing at NTU says he believes the integrtion of VR will enable remote studennts to engage productively with their training and better understand the equipment they equipment they will use on the job better than traditional simulations programs.

“The combination of being able to not only view the equipment and integrate the steps involved with setting up and operating it will be especially helpful,” Halliday says. “We expect that this will shorten the time for the trainees to be effective users of the equipment, speeding up the time to transition from training to employment.”

Dehghan-Niri says the consortium’s support from a wide array of stakeholders, including 12 companies — among them General Electric, Honeywell and Northrop Grumman — along with nine being major defense manufacturers and contractors, demonstrates the potential nationwide impact of the C2D concept.

Demonstrating the potential nationwide impact of the C2D concept, Dehghan-Niri says, it’s noteworthy that the consorium has support from a wide array of stakeholders, including 12 companies — among them General Electric, Honeywell and Northrop Grumman —along with nine major defense manufacturers and contractors demonstrates the potential national impact of the C2D concept.

He notes additional support is coming from the U.S. Department of Energy’s National Nuclear Security Administration and Sandia National Laboratories, as well as four U.S. Congress members.

“This project is about creating what I call a field of hope,” Dehghan-Niri says. “We have established certification programs that enable people to move up from level one to level two and level three certifications, which will then also enable them to get good jobs without going through the full spectrum of higher education in STEM fields. Plus, they will be contributing to something that will help protect their country.”