Ratcheting up research for more resilient concrete pavements

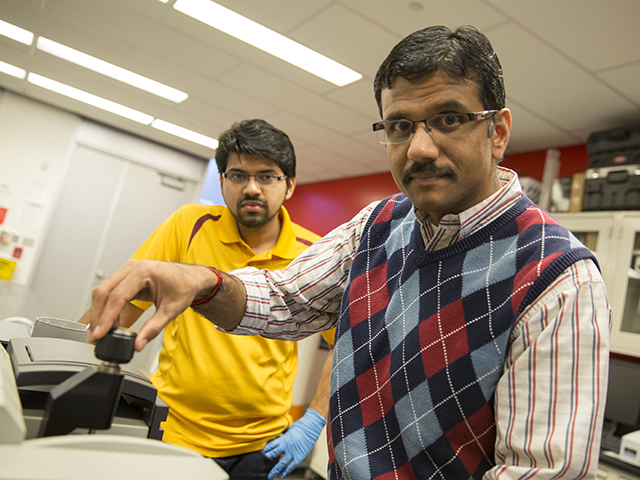

Arizona State University engineer Narayanan Neithalath (at right) will lead an international project to develop ways of making concrete pavements more durable. The work will give several ASU graduate students opportunities to gain research experience. Civil engineering doctoral student Akash Dakhane (at left) will assist Neithalath with tasks such as using infrared spectroscopy to identify the composition of phase-change materials that will be used to make pavements more sustainable. Photography: Nora Skrodenis/ASU

Aging roadways pose a growing threat to transportation infrastructure that’s critical to the health of economies throughout the world.

Beyond the daunting task of funding extensive restoration efforts, there’s an equally pressing challenge to find ways to rebuild major roads that are more sustainable.

The need is one of the main motivating factors behind a new international initiative called Infravation – a combination of infrastructure and innovation.

The European Commission – an offshoot of the European Union – initiated the effort, inviting engineers and scientists in Europe and the United States to propose research projects to develop technological solutions.

The commission considered around 100 proposals. Fewer than 10 have been selected, including two projects to be led by researchers in the United States – one of them by Arizona State University engineer Narayanan Neithalath.

High-performance concrete materials in demand

Neithalath has been experimenting with what are called phase-change materials to produce more resilient concrete surfaces for roads and bridges.

Working with colleagues at the University of California, Los Angeles (UCLA), he is finishing up a National Science Foundation-funded project that is exploring the use of a phase-change material solution for reducing or preventing temperature-related cracks in concrete pavement.

Through the new Infravation project, he and his UCLA partners will expand their work in collaboration with researchers at Delft University in the Netherlands, the Swiss Federal Institute for Materials Science (commonly known as EMPA) and the Tecnalia Research and Innovation organization in Spain.

Since cement concrete is a major component of transportation infrastructure, countries throughout the world are extremely interested in long-lasting and high-performing concrete materials, Neithalath said.

His Infravation group has been awarded $1.6 million to find out if concrete solutions containing a phase-change material can significantly enhance the durability of concrete pavements and bridge decks.

Helping pavements cope with stress

Phase-change materials are substances that respond to temperature variations by changing their state from solid to liquid or vice-versa, and can be sourced from petroleum (such as paraffin wax) or can be plant-based.

“We know how the materials perform under laboratory conditions. Now we have to see if it holds up when applied at larger scales and real-life loading and environmental conditions,” said Neithalath, an associate professor of civil, environmental and sustainable engineering in ASU’s Ira A. Fulton Schools of Engineering.

Like other phase-change materials, the substance his team is working with is especially effective at absorbing and releasing thermal energy. It means that over a wide range of temperature variations, it can store significantly more heat per unit of volume than water, rock or masonry.

That ability makes this phase-change material a good choice for mixing with concrete to boost its resistance to crack-inducing stresses. For instance, in hot weather the material can absorb much of the heat, thus protecting the concrete from a level of heat that can trigger fracturing.

“The important thing is to have a material that helps concrete pavements cope with different kinds of stresses put on it,” Neithalath explained. “You need materials that can melt or solidify in response to varying environmental conditions without weakening the structural integrity of the pavement.”

Goal is to optimize durability

Beyond how well the phase-change material performs in that particular fashion, his team needs to answer other big questions.

What changes in the road design and construction techniques are necessary to optimize the use of the crack-reducing phase-change materials?

What are the most effective ways to embed phase-change material into vast amounts of concrete?

Can the new system provide enough durability to justify additional costs?

How can this phase-change material be safely disposed of when the new road pavements are eventually replaced?

In addition, it will likely be necessary to devise strategies for use of the material on bridge decks that are different than how the material would be used in pavements for roadways built on solid ground.

Finding answers “will require us to more fully understand the properties of the material and how it will behave in a range of situations,” said Neithalath, who is also on the faculty of the graduate studies program in materials science and engineering.

Components for progress in place

Fellow ASU civil engineers on the project team, Subramaniam Rajan and Mikhail Chester, will apply their specific expertise to aid Neithalath in pursuit of answers and solutions.

Professor Rajan will provide computer modeling to validate results of extensive experiments with the material.

Assistant Professor Chester will perform cost-benefit analysis as well as life-cycle analysis of the new pavement material – a major step in predicting how it will measure up to sustainability expectations.

The project will also provide opportunities for a number of ASU post-doctoral lab assistants and engineering graduate students to get valuable research experience.

“We will have good research teams at each of the institutions in different countries that are partners in this project. We have experts for every component of what we need to accomplish our goal,” Neithalath said. “I think we can take concrete pavements to the next level.”

By Joe Kullman