Meet student researchers advancing batteries, semiconductors and additive manufacturing

This article is the first in a two-part series highlighting student researchers and faculty mentors presenting at the Fall 2023 Fulton Forge Student Research Expo on Friday, Nov. 17. Read part two. Learn more about the expo.

Improving microelectronics performance and longevity, simulating semiconductor materials at the nanoscale, charging batteries with movement and using vibrations to improve metal 3D printing are several of the ways Arizona State University students are addressing real-world challenges through hands-on research.

Undergraduate and graduate students in the Ira A. Fulton Schools of Engineering at ASU have several opportunities to apply their knowledge outside of the classroom through research. By working on use-inspired investigations with Fulton Schools faculty mentors, students practice bold thinking to solve problems in the areas of data science, education, energy, health, security, semiconductor manufacturing and sustainability.

The Fulton Undergraduate Research Initiative, or FURI, and the Master’s Opportunity for Research in Engineering, or MORE, programs give participants valuable experiences in which they conceptualize ideas, develop plans and investigate their research questions over a semester.

Students participating in the Grand Challenges Scholars Program, or GCSP, can apply for additional funding to conduct research through the GCSP research stipend program. Conducting research is part of a GCSP student’s rigorous competency requirements designed to prepare them to solve complex global societal challenges.

These programs enhance students’ independent thinking and problem-solving skills and prepare them to solve problems in their communities in innovative ways. The technical skills they gain beyond what they learn in their degree programs better prepare them for industry careers and pursuing advanced degrees.

Each semester, students who participate in FURI, MORE and the GCSP research stipend program are invited to present their findings at a poster session. Formerly known as the FURI Symposium, the Fulton Forge Student Research Expo is the culmination of the students’ hard work to forge meaningful research paths and connections to make an impact. Learn about four students who are participating in the Fall 2023 Fulton Forge Student Research Expo. Meet them and more than 70 other student investigators at the event, which is open to the public, on Friday, Nov. 17, from 1 to 3 p.m. at the Student Pavilion on the ASU Tempe campus.

Photographer: Erika Gronek/ASU

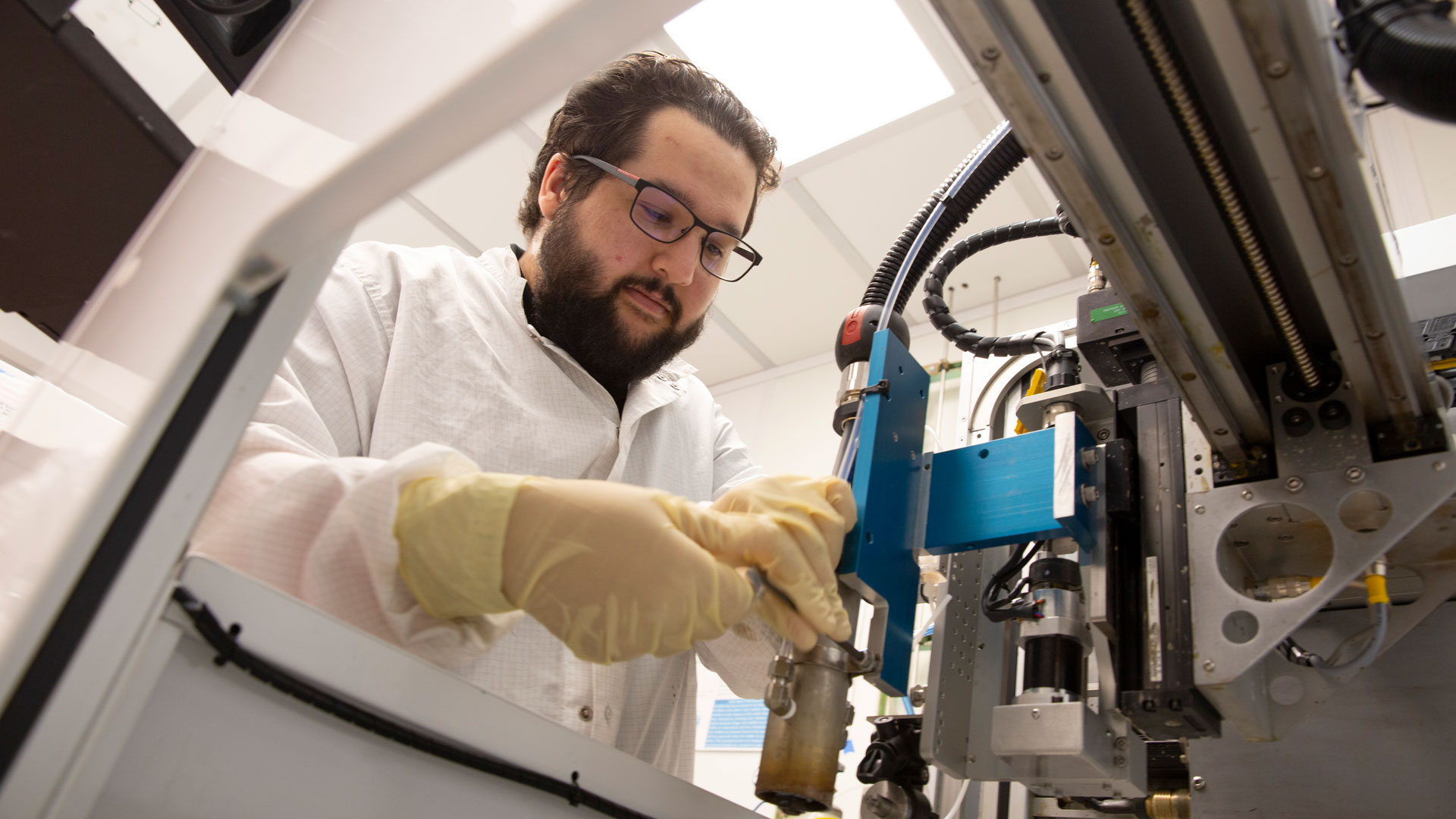

Jacob Burrows

Electrical engineering senior Jacob Burrows is investigating how open-air plasma technology can reduce metal oxidation, which negatively affects performance and longevity when it is present on semiconductor devices’ printed circuit boards. He has been working on this FURI research project under the mentorship of Nick Rolston, an assistant professor of electrical engineering, in the summer and fall of 2023 and was sponsored by the semiconductor foundry TSMC. Sponsorship provides additional funding for undergraduate students to conduct exceptional semiconductor-related research.

Photographer: Erika Gronek/ASU

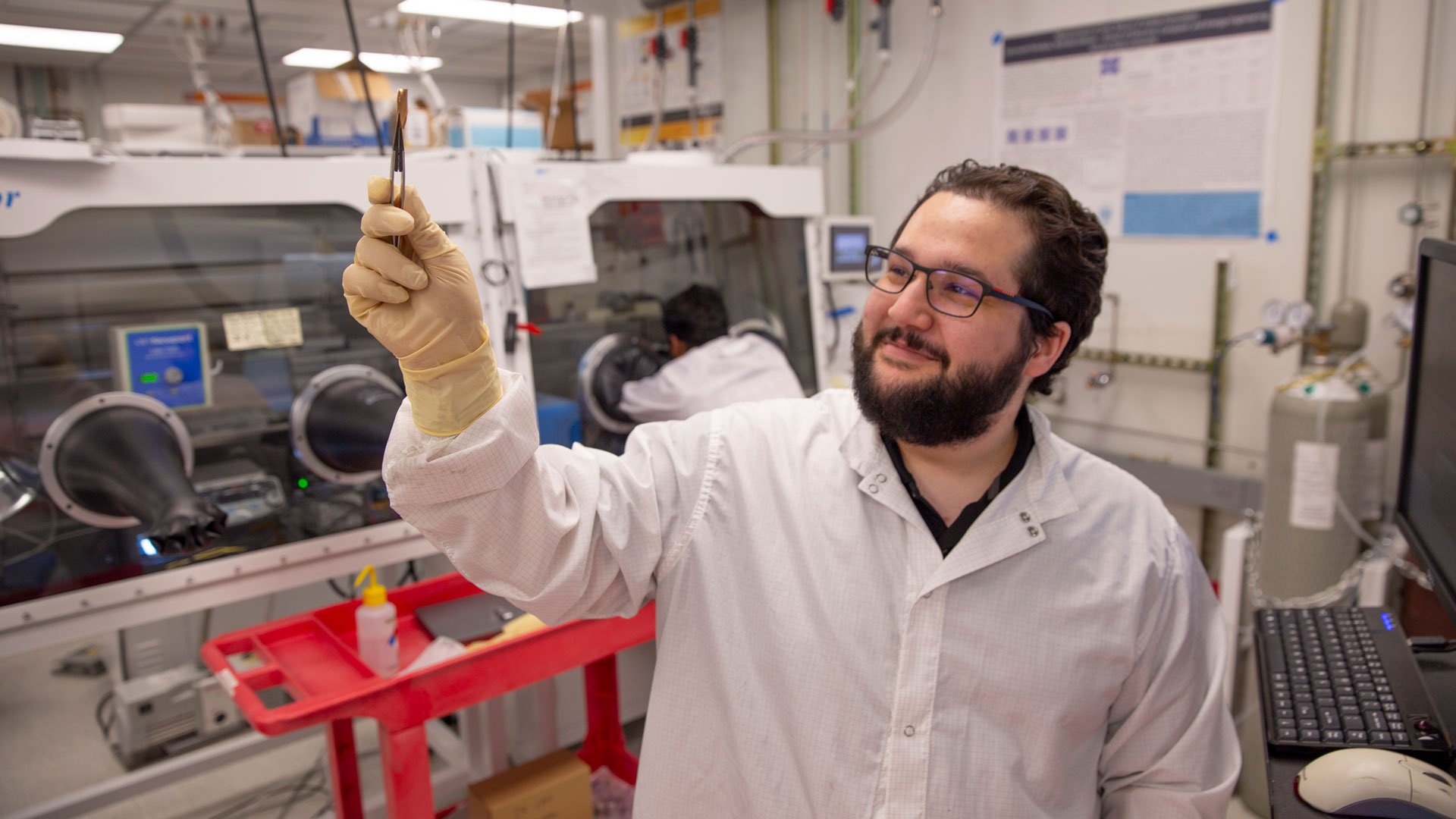

Tyler Norkus

Mechanical engineering senior Tyler Norkus is advancing microelectronics knowledge by simulating what happens to different materials during the manufacturing of semiconductor devices at very small scales — particularly at the nanoscale, which deals with objects tens of thousands of times smaller than the thickness of a sheet of paper. This information can help researchers create better tools to support semiconductor manufacturing. Norkus has been working on this area of research for a year. His work under the mentorship of Masoud Yekani Fard, an assistant teaching professor specializing in mechanical and aerospace engineering, earned Norkus the opportunity to present his research at the American Society of Mechanical Engineers International Mechanical Engineering Congress & Exposition in early November.

Photographer: Erika Gronek/ASU

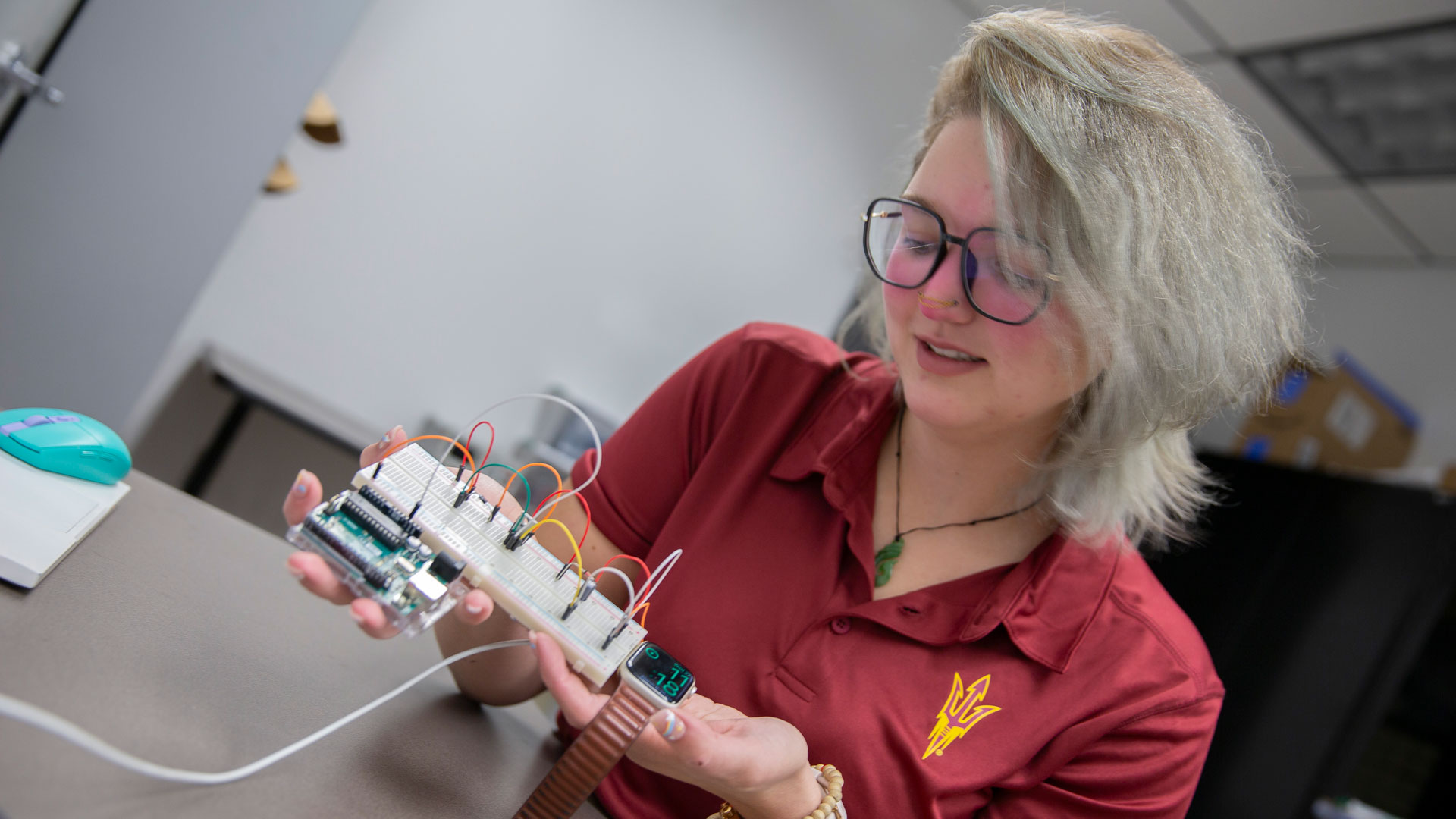

Gwen Eging

Gwen Eging, a sophomore transfer student majoring in engineering with a concentration in robotics, is participating in FURI under the mentorship of Ayan Mallik, an assistant professor of engineering. In her research, Eging is exploring the development and optimization of kinetically charged batteries, which use movement to gain an electrical charge, for use in a wide range of applications from prosthetic devices to smartphones.

Photographer: Erika Gronek/ASU

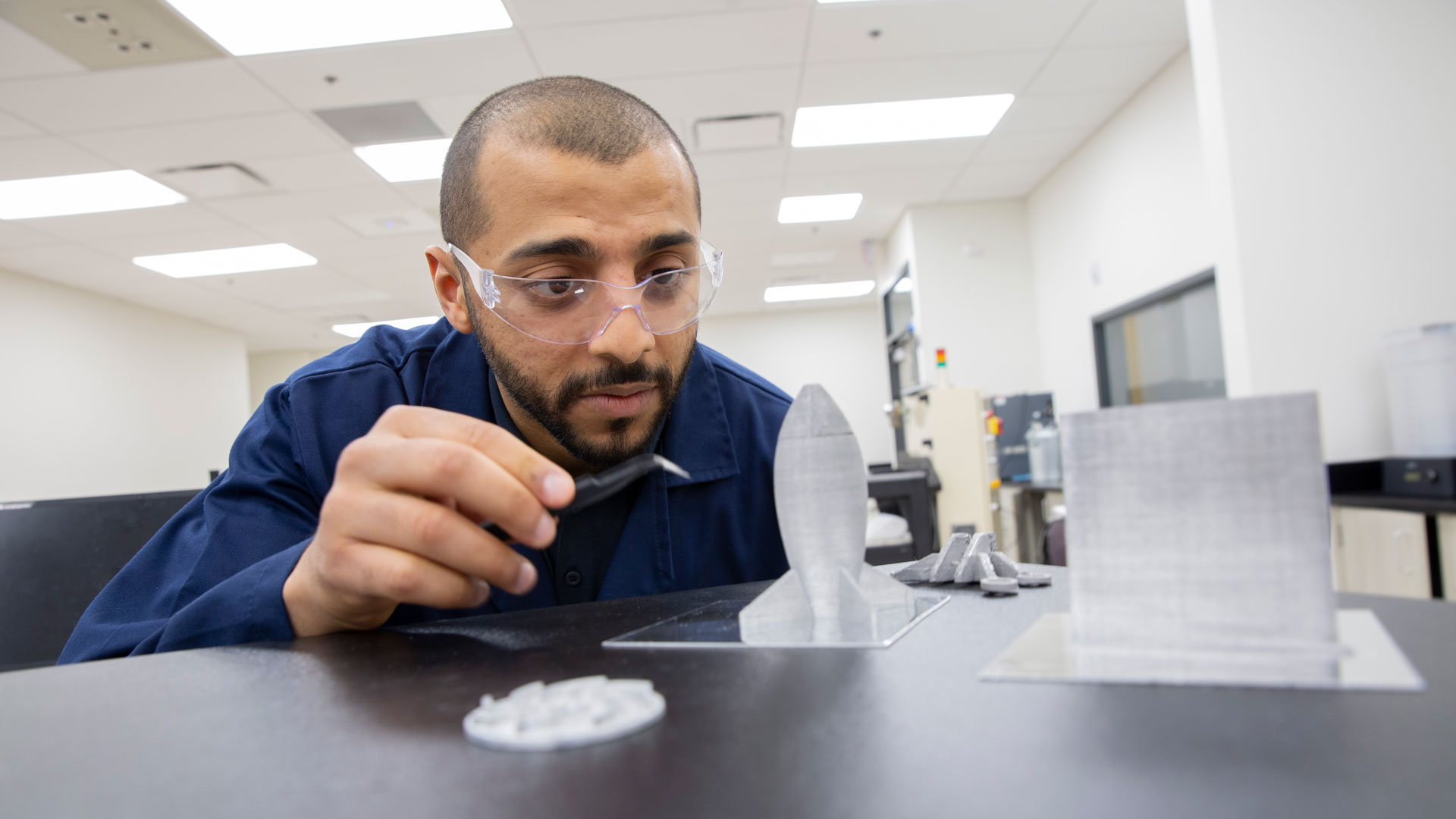

Mohammed Bawareth

Mohammed Bawareth is a manufacturing engineering graduate student participating in the MORE program. Working with Keng Hsu, an associate professor of manufacturing engineering, Bawareth is advancing the understanding of how an additive manufacturing technology that uses vibrations at frequencies higher than the human ability to hear can improve the energy efficiency of metal 3D printing. He was highly involved in research during his mechanical engineering undergraduate studies at ASU through the FURI and Summer Research Initiative programs and has used his work through MORE to support his master’s degree thesis.