Taking batteries B-LO Zero

ASU researcher Nick Rolston is developing solid-state batteries for use in environments with extreme temperatures, such as space

While the coldest temperature recorded on Earth is minus 128.6 degrees Fahrenheit, temperatures in space reach far more drastic extremes: The coldest regions can reach minus 454.81 degrees Fahrenheit.

Given that there is no power grid to plug into, spacecraft such as satellites often use batteries for electrical power to store energy taken in from solar panels. Dominant battery designs use a liquid electrolyte, a key component inside batteries that transports and converts power between the battery’s terminals as it’s charged and discharged. However, this liquid can freeze or operate with much lower efficiency in space’s harsh temperatures.

While onboard battery heaters can prevent freezing, they’re a significant power drain on spacecraft’s limited levels of electricity.

To alleviate the problem, Nick Rolston, an assistant professor of electrical engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, set out to develop a battery capable of functioning at low temperatures with researchers from the Swiss Federal Laboratories for Materials Science and Technology, or Empa.

A cryogenic chamber that will be used in B-LO Zero battery material testing is shown. Photo courtesy of Nick Rolston/ASU

Solidifying batteries for space readiness

Rolston is working with a Swiss team led by Moritz H. Futscher, a scientist at Empa and co-founder and CEO of battery startup company BTRY, to develop solid-state batteries for use in space through a project called “Batteries for Low-temperature Operation < 0C,” or “B-LO Zero” for short. Solid-state batteries’ electrolytes are solids instead of liquids, so they circumvent the risk of freezing or dramatically dropping in performance, like batteries affected by recent winter weather in the United States.

“With all the cold fronts that have hit the U.S., there were some articles I saw about electric vehicles having big issues,” Rolston says. “The technology used is liquid-based electrolytes. If it’s freezing outside, the batteries may be a little bit warmer than that, but the performance drops dramatically to the point of barely being operable.”

B-LO Zero will receive about 350,000 Euros, or about $380,000, in funding from the North Atlantic Treaty Organization, or NATO, Science for Peace and Security Program to explore the properties of different potential electrolyte materials.

Futscher will focus on analyzing materials’ electrical properties, while Rolston will contribute his expertise in the mechanical properties of materials. Rolston plans to examine the effects of extreme cold using a cryogenic chamber and measure materials’ properties such as fracture energy, which measures how much force it takes to rip a substance apart.

The project will primarily focus on ceramic materials, such as those used to make dinnerware and home décor, combined with lithium.

“One of the challenges is making sure the materials are durable,” Rolston says. “They’re quite brittle. If you drop a ceramic, it’ll shatter.”

Futscher says exploring ceramics’ mechanical durability hasn’t been possible for his team alone.

“Nick’s expertise in measuring fracture energy and determining the cause of fractures in devices makes ASU a good collaborator for this research,” he says. “Determining the cause of failure is crucial, and I’m very curious to understand this better.”

In his investigation, Futscher will explore how well the materials serve as electrolytes when exposed to extreme cold. While some materials may perform well in moving ions between electrodes and their applications at normal temperatures, their properties can change unexpectedly with temperature fluctuations.

In addition to extreme cold, the battery materials will have to survive extreme heat. With no atmosphere to provide protection in space, direct sunlight can heat surfaces to more than 200 degrees Fahrenheit, which happens regularly on the International Space Station.

To simulate the rapid swings in temperature the batteries will encounter in space, the cryogenic chambers used for testing will switch quickly between heat and cold during the batteries’ charge and discharge cycles.

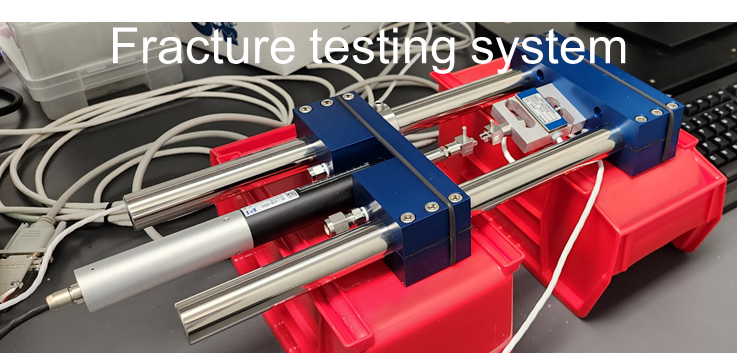

Fracture testing equipment that will be used in B-LO Zero battery material testing is shown. Photo courtesy of Nick Rolston/ASU

Industry-built spacecraft powered by solid-state batteries

The researchers have until the end of 2026 to use their three-year grant to find a battery solution that can endure extreme hot and cold temperature changes. About a year into B-LO Zero, Futscher anticipates hiring a successor to lead the Swiss side as he devotes more energy to BTRY, where he ultimately hopes to be an end user of B-LO Zero.

In addition to BTRY’s interest in the project’s results for industry implementation, other companies in the space sector have also signed on to adopt the technology once it’s ready. ASU NewSpace, which aims to bridge the gap between academic research and its applications in industry, has found two more interested businesses: OffWorld, which builds autonomous equipment for mining in extraterrestrial environments, and Astrobotic Technology, which builds equipment for space missions.

Rolston knew Scott Smas, NewSpace’s associate director, from previous networking in ASU’s space community. Smas believes that NewSpace’s assistance in finding end users during the proposal process and help with writing the proposal boosted the project to gain funding.

“Having interested industry supporting some of these early technology proposals validates that there is a need for the technology,” Smas says. “There’s basic research, and then there’s advancing commercialization. I think being commercialized is the holy grail of everything in tech development.”

Nick Rolston’s research group is looking for undergraduate students to get hands-on experience in next-generation battery and energy storage projects. Interested students can contact Rolston directly at [email protected].