Seeking the next steps forward in shape-recovery metal alloys

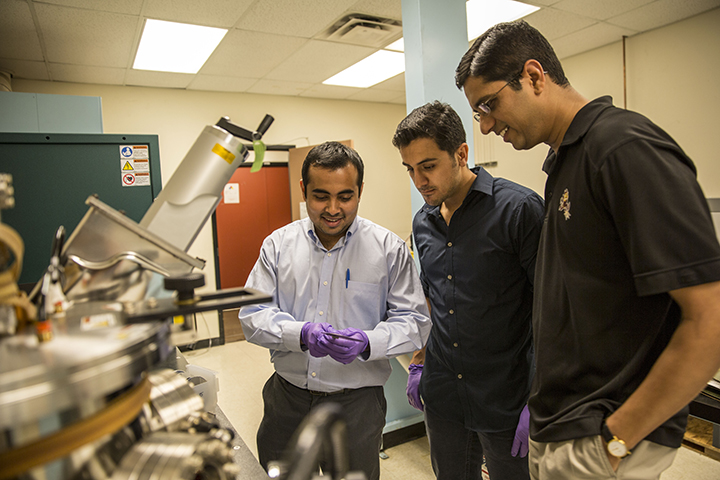

Assistant professor Jagannathan Rajagopalan (at right) is pictured in his Arizona State University laboratory with engineering graduate students Rohit Sarkar (at left) and Ehsan Izadi, who assist with research to better understand the relationship between the microstructure and mechanical behavior of metals and alloys. The National Science Foundation is helping to support Rajagopalan’s project to develop “shape-memory” metal alloys. Photographer: Jessica Hochreiter/ASU

Aerospace, robotic and medical technologies are among those that might be vastly improved if better and less costly “shape-memory” materials can be synthesized.

The term “shape-memory” refers to the ability of materials to essentially “remember” their original shape after being deformed and then being able to regain that shape when an external stimulus — typically heat — is applied.

Imagine, for instance, a scrunched-up metal ball that would spring back to its original shape the way a ball made of a foamy or spongy material can.

The key to producing better shape-memory materials is gaining a deeper understanding of the physics and mechanics that enables materials to achieve such recovery.

Along with that step, it’s necessary to find ways to engineer the microstructures of materials to fully enhance their shape-memory capabilities.

Microstructural alteration

Jagannathan Rajagopalan’s work on both of these steps has earned him a National Science Foundation (NSF) CAREER Award, which will provide close to $520,000 over five years to support his research.

CAREER Awards are given to young scientists and engineers who have the potential to become education and research leaders in their fields and are doing work considered important to national interests.

Rajagopalan is an assistant professor in the School for Engineering of Matter, Transport and Energy, one of the Ira A. Fulton Schools of Engineering at Arizona State University.

He teaches in the mechanical and aerospace engineering program, and also serves as an advisor to graduate students in the materials science and engineering program.

With his new NSF award, he will expand his studies to determine what microstructural characteristics of various metals and alloys give them shape-memory capabilities, and learn how to alter their microstructures to optimize that capability.

The research involves detailed investigations from the macroscopic to the microscopic level. Metallic structures are typically made up of millions of grains. The materials Rajagopalan will study for the project are composed of extremely tiny (nano scale) grains. Manipulating these small grains can have a big impact on the characteristics of the metals.

“The size, distribution, geometry and orientation of the grains determine the strength and toughness of the materials at the macro structural level,” he explained.

State-of-the-art research tools

It takes high-powered electron microscopes to characterize and understand the properties of microstructures composed of such tiny grains.

The facilities at ASU for such research may have been a factor in the NSF’s decision to support the project.

Rajagopalan has access to the electron microscopes at ASU’s LeRoy Eyring Center for Solid State Science and to labs designed for the fabrication of advanced micro-electro-mechanical (MEMS) systems and devices necessary for his work.

“The facilities provide state-of-the-art equipment with unique capabilities,” he said.

Using these tools should help him realize his project’s most ambitious goal: finding ways to make a material’s shape-memory capability permanent.

“The idea it to take things a step further – to know how to alter the microstructure so that metals can regain their shape not only once or a few times but over and over again,” Rajagopalan said.

That achievement could lead to improvements in cardiac stents – the metal tubes that hold coronary arteries open to allow blood to flow freely and prevent heart attacks.

Such shape recovery would also advance development of “smart materials” that would enable aircraft and other vehicles to self-repair structural damage, and to prevent damage to actuators used in robotic devices.

Learning, research opportunities for students

The NSF award also will enable Rajagopalan to do educational outreach. He will organize a program to give high school students opportunities to learn about research by visiting ASU labs, talking to faculty and performing basic experimentation.

He also will provide workshops to help high school teachers incorporate lessons about the research into their class instruction, and offer training in materials research for university undergraduate and graduate students.

An ASU engineering doctoral student will get an opportunity to work on the project with Rajagopalan, and two undergraduates will get research experience while also helping with outreach activities.

Rajagopalan earned bachelors and master’s degrees in mechanical engineering from the Indian Institute of Technology Madras and a doctoral degree in the field from the University of Illinois at Urbana-Champaign.

His research has been published in several prominent journals, including Science, Nature Communications, Biophysical Journal and Acta Materialia.

Media Contact

Joe Kullman, [email protected]

480-965-8122

Ira A. Fulton Schools of Engineering