Center adds new dimension to ASU’s material science research

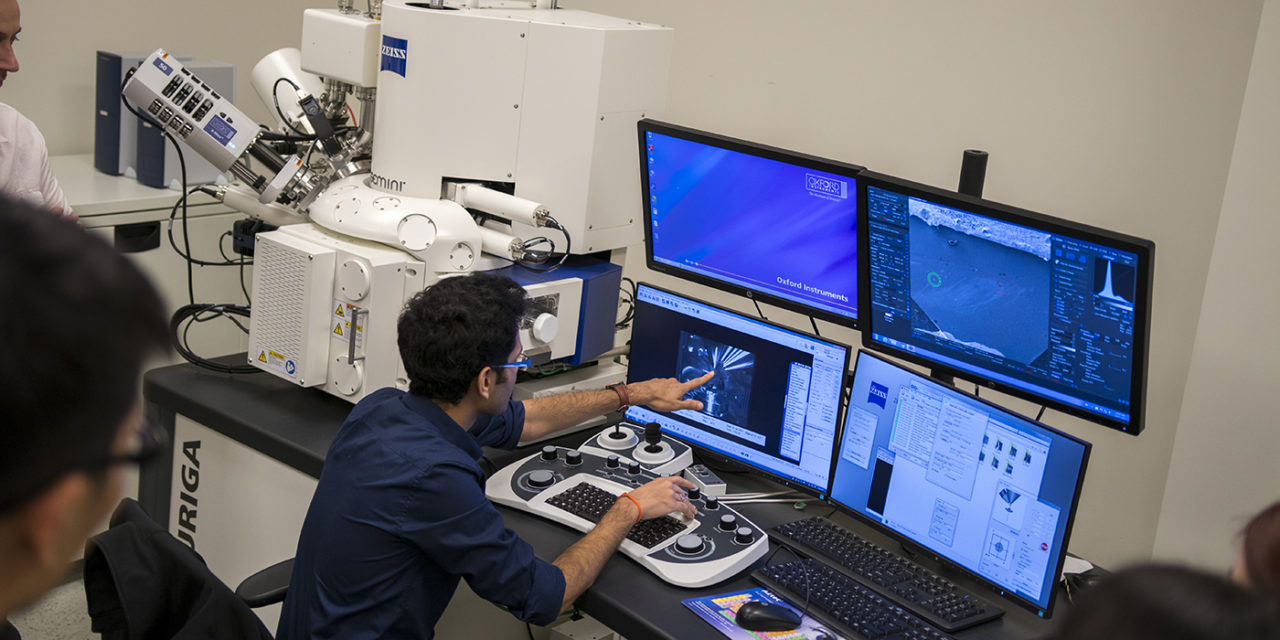

Above: Researchers, stakeholders and partners view a demonstration of new equipment in the Center for 4D Materials Science, or 4DMS, to gain an understanding of the center’s new capabilities for materials science research. Photographer: Marco-Alexis Chaira/ASU

A new research center, devoted to studying the structure of advanced, high-performance materials in three dimensions was established within the Ira A. Fulton Schools of Engineering earlier this month.

Headed by Nik Chawla, Fulton Professor of Materials Science and Engineering and funded by a collaboration between Arizona State University, Zeiss and the Office of Naval Research, the Center for 4D Materials Science, or 4DMS, provides a unique and ground-breaking dimension to materials research — time.

The foundation of materials science and engineering is the understanding a material’s structure and how that affects properties and performance. 4DMS will build on that foundation by granting researchers the ability to monitor and analyze materials in real-time.

“We typically think of sectioning a material and looking at its structure in two dimensions, which can often lead to limited or erroneous results and interpretations. With the new center, we are looking at a new paradigm in materials science — studying the structure of materials in three and four dimensions,” said Chawla at the outset of a two-day kickoff event for 4DMS.

4DMS Director Nik Chawla, Fulton Professor of Materials Science and Engineering, speaks at the outset of a two-day kickoff event that opened the new research center. Photographer: Marco-Alexis Chaira/ASU

4DMS will explore material science with multiscale modeling and characterization of materials under different stimuli, such as mechanical, thermal, electrical and more, over time. The Center has brand new, state-of-the art equipment and capabilities, including x-ray microtomography that boast resolution of less than one micrometer and focused ion beam microscopy with resolution at the nanometer scale. In addition, the Center will house a first of its kind lab-scale diffraction contrast tomography system to study the crystallography of materials in 3D and 4D.

The cutting-edge equipment enables researchers to witness and analyze the deformation of microelectronic packaging or the corrosion of or crack propagation in materials as it happens on a macro- or nanoscopic level. This capability will not only lead to a broader understanding of materials’ chemical and physical structures, their limitations and strengths, but will lead to the fabrication of the next generation of materials for a variety of applications.

Along with Chawla, additional faculty from the School for the Engineering of Matter, Transport and Energy will be working in the Center, contributing to research projects, including Associate Professors Yongming Liu and Kiran Solanki as well as Assistant Professors Yang Jiao, Konrad Rykaczewski and Jagan Rajagopalan. True to 4DMS’ interdisciplinary nature, Professor Narayanan Neithalath of the School of Sustainable Engineering and the Built Environment will bring his expertise in sustainable construction materials to the Center as well.

4DMS held a kickoff event on January 20 and 21, convening stakeholders and collaborators to discuss the new center and its research.

“This is about partnerships,” said Fulton Schools Dean Kyle Squires at University Club on January 19. “We can’t achieve big goals without partners who are really invested, and Nik’s center is a good example.”

Though a joint investment of $4 million from ASU, Zeiss and ONR got 4DMS started, additional sponsorship came from government agencies Los Alamos National Lab, the National Science Foundation, the Air Force Office of Scientific Research and industry partners Qualcomm, Toyota and Intel.

Squires also lauded the Fulton Schools faculty as integral to the future success of 4DMS and its research. “The scale and the depth of what they’re working on is impressive. It’s as good as any place else, and I think that was an attractor for Zeiss. Everyone here is working at the top of their field.”

Arno Merkle of the Materials Science Group at Zeiss, echoed Squires’ thoughts on the importance of partnership.

“We have a thousand ideas and we can only invest in a few to do them well,” said Merkle. “Part of our process of doing that is going out to Nik, who is one of the leaders in the community and seeing beyond the next five, ten years and really validate a certain modality will have utility for the science in the future.”

During the event, Chawla noted that Sethuraman “Panch” Panchanathan, Executive Vice President and Chief Research and Innovation Officer of Knowledge Enterprise Development, was instrumental in getting the center started and off the ground. He recalled walking into Panchanathan’s office years ago to pitch him the idea.

“Many people walk into my office,” said Panchanathan. “But it’s very easy to invest in initiatives when you know the idea is fantastic, when you know we have a fantastic leader with a fantastic team.”

Director of the Advanced Materials Initiative at ASU Bill Petuskey’s remarks centered around the university’s status as a leader in materials science.

“ASU has had a long history in developing new technologies and applying them in characterizing materials at very fine scales,” said Petuskey, pointing to the LeRoy Eyring Center For Solid State Science as a particular example of the university’s excellence in the field.

Researchers, partners and stakeholders in the Center for 4D Materials Science, or 4DMS, gather before Old Main on the Tempe Campus for a group photo during the center’s two-day kickoff event. Photographer: Marco-Alexis Chaira/ASU

Holding up his mobile phone, Petuskey said “We can think of this as a collection of many materials that are slapped together to create functionality, but in a sense, it’s one very complex material that consists of individual components, interfaces as well as the software that is embedded. Looking at making materials more complex gives us that functionality we need.”

Jim Sharp, President of Carl Zeiss Microscopy, LLC., spoke of the importance of keeping close ties with researchers working with his company’s equipment.

“Typically, the day we ship a new machine, we know more about it than anyone else in the world. About six months later, guess who knows more about that machine than we do? You do,” he said to the room of researchers. “Because you’re doing things with it we couldn’t possibly do. And if we don’t stay collaborative with you, we’ll go out of business.”

The second day of the event consisted of interactive sessions hosted by representatives from both Zeiss and ASU in the 4DMS facilities housed within Interdisciplinary Science and Technology Building 4.

“This truly reflects what ASU stands for, which is bringing together transdisciplinary group of people to work,” said Panchanathan, pointing to the array of disciplines involved in 4DMS, from materials science, mechanical and civil engineering to chemistry, physics and computer science. “Problems are not one-dimensional. It requires inspiration from multiple disciplines to bring real solutions to problems, and that what ASU prides itself on.”