Kitchen cooks up automated design leading to faster, lighter electronics

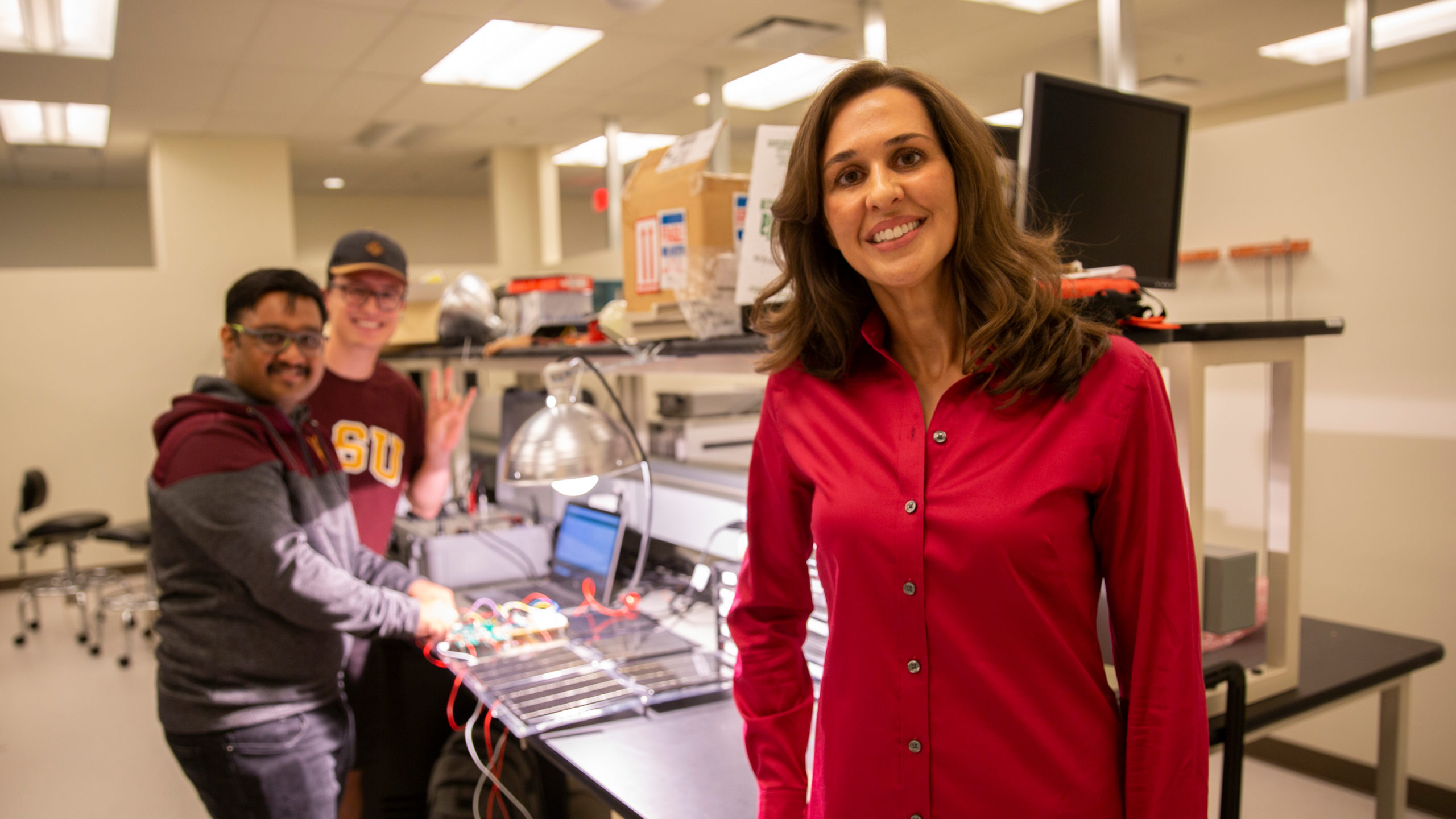

Above: Jennifer Kitchen is working to automate the design process of power electronics, systems of circuits that regulate the flow of power through an electronic system which are found in many types of electronic devices. Photographer: Erika Gronek/ASU

Twelve faculty members in the Ira A. Fulton Schools of Engineering at Arizona State University received NSF CAREER Awards between November 2019 and April 2020.

Ever wonder why the battery in your phone drains so quickly? While screen time is a major factor in battery depletion, behind the scenes, some of your battery’s energy is also being siphoned off by your phone’s power converter.

Jennifer Kitchen, an assistant professor of electrical engineering in the Ira A. Fulton Schools of Engineering, has received a 2020 National Science Foundation Faculty Early Career Development Program (CAREER) Award to work on the design automation of power electronics. This recognition is reserved for researchers who show the potential to be academic role models and to advance the missions of their organizations. CAREER awards provide approximately half a million dollars over five years to further each recipient’s research.

Kitchen’s work is intended to open doors to a future of low-cost, energy-efficient and high-performing power electronics in all types of electronic devices.

Power electronics are systems of circuits that regulate the flow of power through an electronic system. They are found in a multitude of devices from mobile phones to spaceships. These devices have undergone rapid development in recent years to constantly produce new and better products, but the process of producing these improved power electronic systems takes much longer.

“A lot of consumer-based devices like ‘internet-of-things’ devices, smartphones and tablets have very rapid development cycles,” says Kitchen. “Unfortunately, the power electronics industry can’t yet support that rapid development cycle. The design cycle for integrated electronics takes over a year, and it needs to be within months. To help do this, I proposed to automate the design process.”

While current methods for automating design processes are optimized for digital systems, power electronics have both digital and analog components.

“The reason that people haven’t automated power electronics is there wasn’t a need until recently,” says Kitchen. “But also, it’s very challenging because power electronics are not just one type of circuit; they are a system. This [automation] is something that is usually done by computer systems, but we are going about it from a hardware perspective. It’s not really something that’s been done before.”

Over the next five years, Kitchen, who is also an ASU alumna, plans to apply various programming methods of design automation at different levels of the system, optimizing the design to a few different parameters, including energy efficiency, size and weight.

“For instance, we might use analytical models to select the best architecture for the system, but we might use geometric programming with statistical models to select the best circuits,” says Kitchen. “It’s going to be a combination, most likely, of different programming methods.”

Kitchen expects that automating the design process for power electronics will not only speed up the development cycle, but will also result in lower-cost, higher-performing systems.

Typically, artificial intelligence will select the most optimized design, and there’s a good chance that it will be a better solution than the designer may have thought of, she says.

“We always talk about cell phone battery drain,” says Kitchen. “The electronics drain the battery, but the power electronics also drain the battery. The power electronics system for converting the battery voltage to a voltage that all of your electronics can use has limited efficiency. If you can improve the efficiency of the power electronics system, decrease their size and decrease their power consumption, overall you improve the energy efficiency of electronics.”

A design that is optimized to be smaller and lighter will also cost less. Internet of things devices such as smartphones, tablets and laptops would not only be faster, but also cheaper and more manageable.

Eventually, Kitchen hopes to apply these design automation methods to other complex electronic systems, such as those used in frequency synthesis and cellular applications, and in future industrial applications.

“I am excited to train students in both hardware circuit design as well as the automation aspect,” says Kitchen. “Those that graduate in the courses that we teach on this are going to know how to design for automation and how to automate design. They’ll have programming knowledge as well as circuit design knowledge. I feel that that’s the future of hardware.”