Fulton Schools students build a car and skills with chemistry

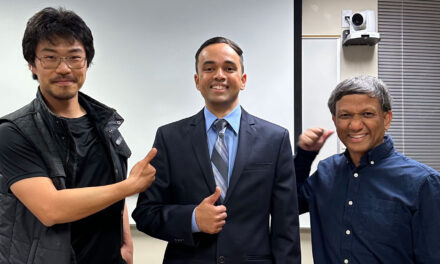

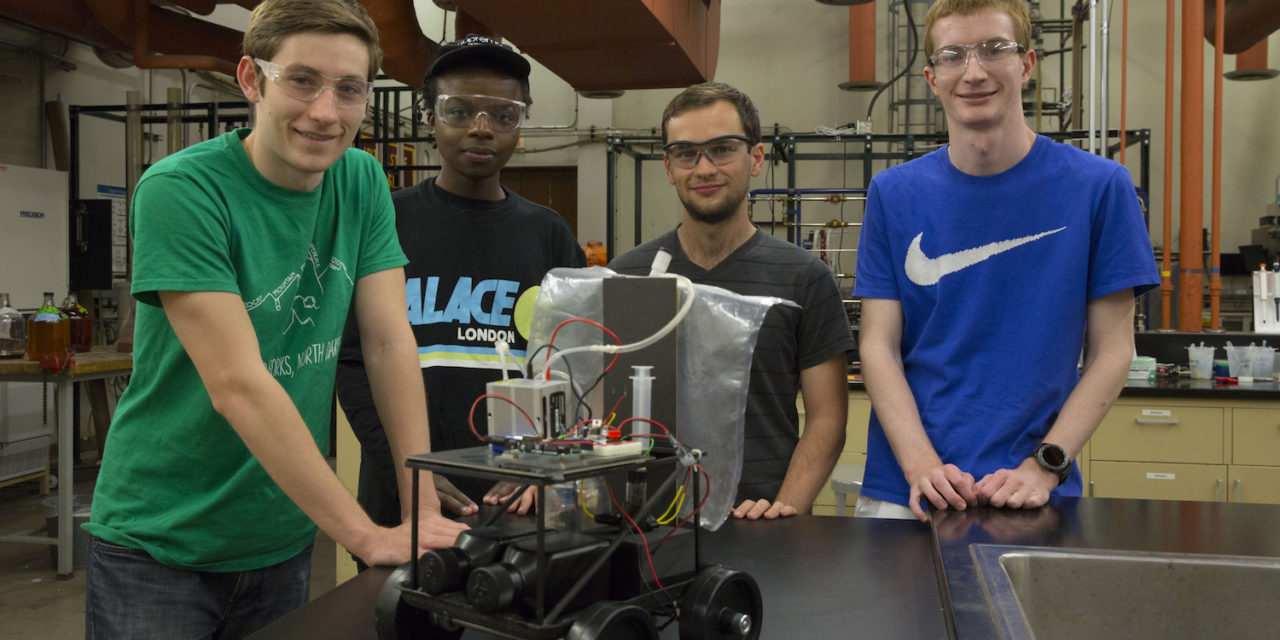

Above: Jayse Langdon, Jon Simiyu, Andrew Dopilka and Alex Cook work on their fuel-cell-powered car in preparation for the national American Institute of Chemical Engineers’ Chem-E-Car competition this November. Photographer: Pete Zrioka/ASU

Fred is teaching five engineering students out-of-the-box thinking that applies their technical and project management skills. Fred just happens to be a shoebox-sized, fuel-cell-powered car.

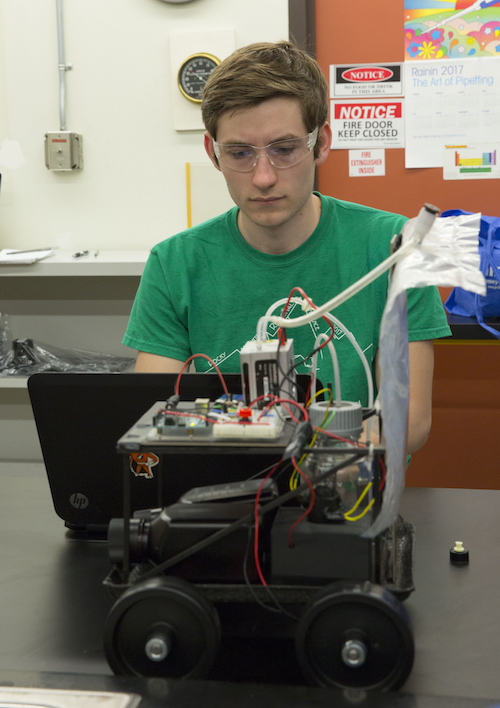

Team president and recent chemical engineering graduate Jayse Langdon hopes more students will take on the challenge as current team members begin graduate studies in the fall. The team’s innovative design ideas earned them second place in the 2017 AIChE Rocky Mountain Regional Conference competition in March and they’re looking for fresh talent to keep the team competitive. Photographer: Pete Zrioka/ASU

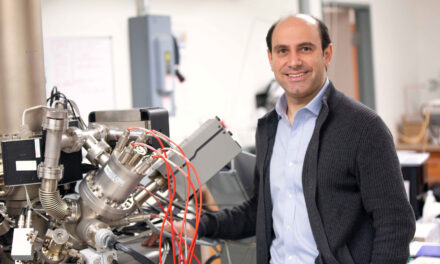

This project is a creation of Arizona State University’s Chem-E-Car competition team, comprised of chemical engineering recent graduates Jayse Langdon and Andrew Dopilka, chemical engineering undergraduate students Alex Cook and Jon Simiyu, electrical engineering undergraduate student Nathan Rodkey and mentored by Ira A. Fulton Schools of Engineering chemical engineering Assistant Professor César Torres.

The Chem-E-Car competition, led by the American Institute of Chemical Engineers, challenges college students to design and build a model car powered by a chemical energy source.

The ASU Chem-E-Car team’s car is powered with a fuel cell that runs on hydrogen gas and oxygen to create water and a current for a consistent chemical reaction to drive the car forward.

The team placed second in the 2017 AIChE Rocky Mountain Regional Conference competition in March, securing them a spot at the national tournament in Minnesota this November.

Driving Fred forward with unique solutions

Dopilka and Langdon competed in the 2016 Chem-E-Car competition with a fuel cell car based on the successful 2012 ASU Chem-E-Car team’s design. Though they didn’t place in 2016, they have used that experience to revitalize Fred in 2017 to successfully complete the competition’s difficult challenge.

An hour before the competition, student teams are given a specified weight the car must carry safely over a specified distance, and they must stop as close as they can to the finish line. They have two rounds to get their best score.

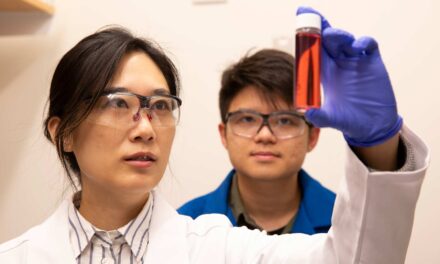

The team put their engineering skills to use to design a successful system. A highly accurate iodine clock, which they consider the best part of their car so far, determines the amount of time the car moves based on the amount of chemical supplied.

“We combine two solutions onboard the car, and when one chemical runs out it turns from clear to dark. A photoresistor sensor detects the change in color and it cuts the power circuit,” Langdon says.

For even more accurate results, the team designed a custom stir plate to ensure the solution is well mixed, which Langdon thinks helped make theirs the best stopping mechanism demonstrated at regionals.

They also follow the “measure twice, cut once” philosophy — taking measurements at ASU and in the competition preparation time to ensure accuracy, something they didn’t see other teams doing.

Torres sees a lot of potential in this team as they’ve refined Fred over the last two years, though he knows national competitions are tough and require a lot of practice.

“Having seen a few national competitions, I know the top places are decided by inches from the finish and this requires extensive testing of the car,” Torres says. “Their success is highly dependent on how much time they can put into testing.”

Success is more than just chemical engineering

Until 2016, the Chem-E-Car team was part of the Controlled Propulsion special topics course that Torres has been running since 2011, but was far from a typical class experience.

Torres designed the course to be an independent learning experience — from designing the chemical reaction to setting up team meetings, assigning tasks and buying supplies. This challenges team members to use much more than technical skills to succeed.

“There’s a structure in labs, but here we’re just making it up as we go,” Dopilka says. “No one is telling us what to do or what to look for.”

The Chem-E-Car team is now part of the AIChE club where it continues to challenge Fulton Schools students.

It’s a rewarding experience when they get it right after all their hard work, and a great way to show how they’ve applied their classroom skills.

“You don’t get this learning experience in the classroom or labs,” Langdon says. “You’re forced to use things you’ve learned in an actual applied setting.”

Torres says it’s a great opportunity to show applied knowledge and more.

“It is an opportunity to put all their knowledge together into a specific design problem,” Torres says. “It also helps them develop their leadership skills and their ability to work in teams that coalesce into a successful design.”

Preparing a formula for nationals and beyond

They’ll be further optimizing the design of the various components of the car and trying out alternative designs using batteries over the summer.

No matter how they place, the team is looking forward to meeting other chemical engineering students from across the country and even around the world, one of their favorite parts of the regional tournament.

They also hope to have more Fulton Schools students join their small team, especially with Langdon and Dopilka beginning graduate studies at ASU in the fall.

Torres is confident that students will seek out this opportunity out of an interest in accomplishing the Chem-E-Car challenge.

Langdon says it’s a fun experience to use skills learned in the classroom on something other than homework, and emphasizes that the technical and project management skills gained are valuable to employers.

“We hope that our success inspires more students to join and make a tradition of success here at ASU,” Langdon says. “We’ve got a big program with a lot of smart people, and we hope the younger classes set out to prove that.”