Eileen Seo to tackle materials’ sustainability with DOE’s Early Career Research Award

If you’ve ever slightly cut yourself, you know that your skin can often repair itself fairly quickly. But that’s not the case with commonly used products made of polymer materials, like plastics. Wouldn’t it be helpful if your next plastic product could also repair itself when damaged?

One million plastic bottles are purchased every minute, and up to five trillion plastic bags are used worldwide every year according to the United Nations Environment Programme. Yet, the durability and resistance to degradation that make polymers extremely useful are the same that make them one of the biggest threats to humanity. Shockingly, half of all plastic produced is designed to be used just once and then thrown away, leading to some of the catastrophic environmental, health and economic problems we face today.

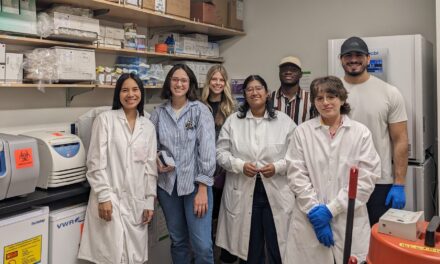

The U.S. Department of Energy has selected S. Eileen Seo, a joint assistant professor of chemical engineering in the School for Engineering of Matter, Transport and Energy and Biodesign Center for Sustainable Macromolecular Materials and Manufacturing, part of the Ira A. Fulton Schools of Engineering at Arizona State University, for the prestigious 2024 Early Career Research Program Award. Seo is one of 91 awardees from 50 universities and 12 national laboratories to receive the award this year.

Her research is aimed at creating a novel approach to manufacturing mechanically robust, self-repairing polymeric materials using nanotechnology. Seo’s approach requires comprehending how self-repair works at the nanoscale in a polymer network. Self-repairing in living things occurs through dynamic interactions; the bonds must be weak enough to connect on and off. The reason why mechanically robust polymer products don’t self-repair is that they form via strong irreversible covalent bonds — once the bonds are formed, they stay that way.

“Our goal is to use dynamic bonds, like physical bonds, to engineer the ability to reversibly bond with each other,” Seo says. “The issue is that while dynamic, physical crosslinks are often very weak bonds, limiting self-repairing properties to relatively soft materials.”

Seo is making significant progress toward tackling the challenge of engineering self-repairing properties in more mechanically robust material systems. She proposes to design multivalent nanoparticle-based bonds functionalized with small molecules that form complementary physical bonds with polymers, thus enabling self-repairing in polymer networks.

“Even though the individual ligand-polymer bonds are weak, they become a lot stronger when combined,” Seo says.

Making great strides towards a sustainable future

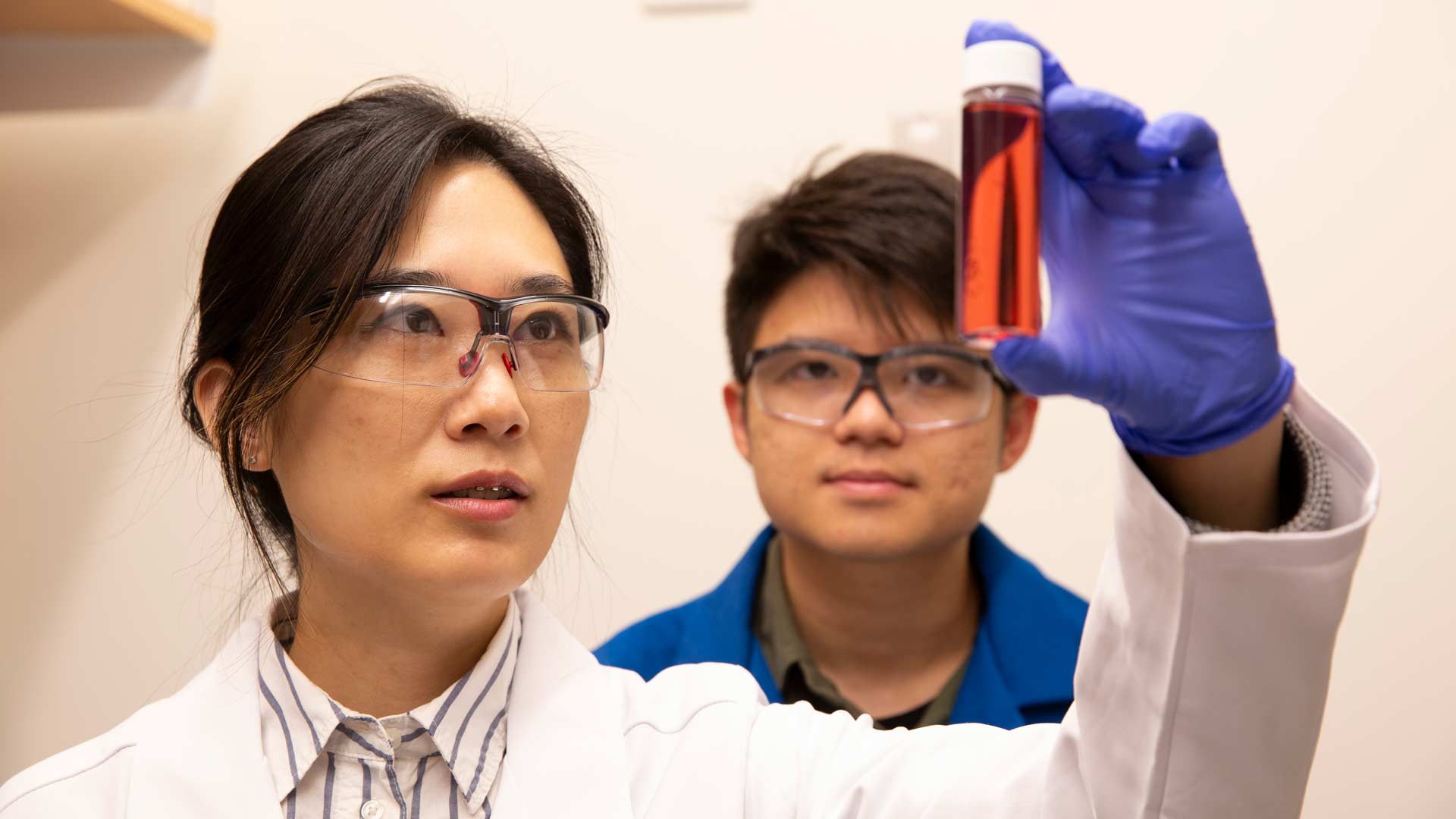

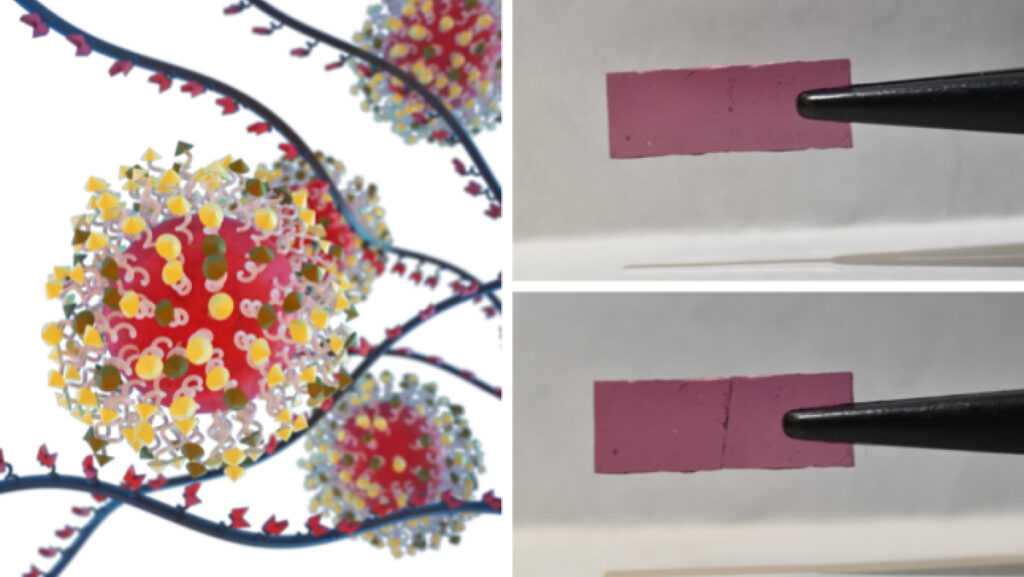

Left, top to bottom: an illustration of self-repairing polymers facilitated by nanoparticle-based bonds, art courtesy of Jason Drees/ASU and a material’s self-repairing process from before fracture to after self-repairing. The material contains polymer and surface-modified gold nanoparticles to accelerate the self-repairing of polymer nanocomposite through complementary hydrogen bonds at the interface. Seo says these materials exhibit a high stiffness and recover more than 95% of bulk properties after self-repairing. Photos courtesy of S. Eileen Seo

Seo says there is a limited understanding of what happens at the interface between polymers and nanoparticles and its effect on bulk properties — specifically, the bonding mediated by the molecular layer between polymers and nanoparticles.

With DOE’s support, she plans to delve deeper into the molecular interfacial interactions’ impact on the overall properties of the polymer composites, including properties that would enable self-repairing capabilities.

“We published a paper recently in the Macromolecules Journal showing that controlling the number of small molecules that can bind to polymers has a huge impact on the collective mechanical behavior of a polymer network,” says Seo.

A key element of her proposed system is light. As part of her research, Seo plans to introduce stimuli-responsiveness at the polymer-ligand interface to see how they change the network’s structure and material properties.

“Self-repairing and high mechanical properties are difficult to simultaneously engineer in a material, as these properties are often in tension with each other,” she says. “What I’m proposing is to introduce multivalency in polymer products using nanoparticle systems such that we have higher mechanical properties. Then, shine a light to decouple some of the bonding between polymer and ligands, to lower the multivalency and allow for self-repairing.”

Seo emphasizes the novelty of her research saying, “enabling dynamic interactions at the molecular level where the material can respond to environmental stimuli and autonomously heal itself is an important step in moving beyond traditional polymer nanocomposite systems.”

Impact at a large scale

The Early Career Research Program Award is part of DOE’s strategy to develop the next generation of engineering and scientific researchers and affirm America’s role as a driver of science and innovation around the world. The award will provide approximately $1 million over five years in funding to accelerate Seo’s research and help her assemble a group of students to support the endeavor.

“I hope to convince people that there is a different way of engineering polymer networks,” says Seo, detailing what she looks forward to in the next five years. “Just like the way protein runs the functions of our body, I hope to understand better how nanoparticles can control bonding interactions for nonliving things, like polymer materials.”

This approach not only enhances the longevity and performance of polymer products but also opens up new avenues for creating more sustainable, adaptable materials in a wide range of applications, from coatings to biomedical devices.

“People wouldn’t have to throw polymer products away when broken; they would have a mechanism to put them back together until they decide to throw them away and recycle through disassembly,” Seo says. “We would prolong their lifetime and improve their recyclability.”