Sub-zero sustainability

An ASU research team’s energy-saving solution for frozen food storage could mean big costs savings

Above: An Arizona State University engineering team is working with the Salt River Project utility, the Viking Cold Solutions company and the Bashas’ Family of Stores grocery chain on a thermal energy system to reduce the costs and the amount of electrical power needed to keep large food storage facilities refrigerated at sub-zero temperatures. Pictured (left to right) holding frozen ice cream are Associate Professor Robert Wang, doctoral students Prathamesh Vartak and Neda Askari and Associate Professor Kristen Parrish. Photographer: Marco-Alexis Chaira/ASU

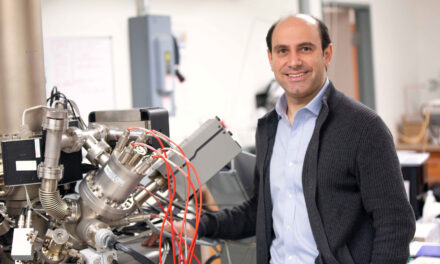

Kristen Parrish’s work focuses on integrating energy efficiency methods into the design, construction and operational processes of buildings.

Robert Wang’s expertise in thermal science includes the applications of thermoelectricity, thermal energy storage and phase change materials and processes.

With those combinations of skills, together they are a formidable force in the quest for well-preserved, quality ice cream.

Their know-how is especially valuable if you have very large facilities filled with vast quantities of food that must be kept frozen under precise technical specifications to maintain its optimal attributes as an edible.

Parrish and Wang, associate professors in Arizona State University’s Ira A. Fulton Schools of Engineering, are working on just such a project with Arizona’s Salt River Project water and power utility and Viking Cold Solutions, the leading thermal energy storage provider to the low-temperature cold-storage market.

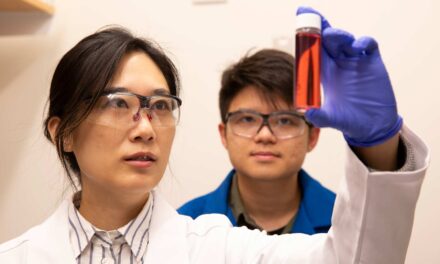

The thermal energy system being tested in a Bashas’ ice cream freezer employs “ice packs” of phase change materials that can transform repeatedly from liquid to solid and back to liquid again. The materials are encased in plastic and placed on the racks of shelving throughout the storage facility. Photo courtesy of Salt River Project

The companies and the ASU researchers are experimenting with Viking Cold Solutions’ novel thermal energy storage and cooling technology in the 10,400-square-foot ice cream freezer in the Bashas’ Family of Stores grocery chain’s 800,000-square-foot distribution center in Chandler, Arizona.

The ice cream freezer uses a good portion of the total power required to operate the entire facility that hums constantly with the running of refrigeration equipment and electrical systems.

“Annually, the facility requires the equivalent amount of energy needed to power almost 1,000 homes for a year,” says Chico Hunter, SRP’s research and development manager.

That includes providing the energy to keep the ice cream storage space at a constant minus 18 degrees Fahrenheit.

Parrish and Wang, along with Nexant, an industrial energy consulting and services company, are monitoring and measuring the performance of the system, which offers the advantage of a low-tech chemical and mechanical cooling technique.

The thermal energy system utilizes proprietary, food-safe phase change material formulas comprised of deionized water and inorganic salts held in individually sealed plastic cells. The cell modules are designed to be installed above the storage racks in the ice cream freezer.

As phase change material transitions from liquid to solid and from solid to liquid, the system absorbs or releases large amounts of energy while maintaining a stable temperature.

“It’s sort of like the ice packs you put in your lunchbox,” Parrish says. “They store the cold. The idea is to get enough cold stored in them that you can run the refrigeration compressors in the freezer for a lot less time during peak hours and still maintain the same cold temperatures throughout the storage space.”

“Keeping a space cold is essentially a process of removing heat,” Wang explains. In this system, as the phase change material encased in the plastic melts, “it absorbs the surrounding heat and keeps the freezer cold.”

An important feature of the method is “it’s a passive energy process,” Wang adds. “No electricity is needed to drive the melting process of the phase change material.”

The benefit SRP and Bashas’ hope to reap from the project is not simply energy efficiency but also significant energy costs savings. The thermal energy process enables Bashas’ to reduce the amount of time it has to run the facility’s conventional electrical refrigeration system during more expensive peak load hours — that’s between 2 p.m. and 7 p.m. each day when customer demand is highest for SRP and when the cost of power is up to three times as high as during nonpeak hours.

Bashas can now run the electrical refrigeration system mostly during nighttime hours when costs are lower.

“The less expensive and more efficient nighttime refrigeration run time refreezes the phase change materials, and those ice packs are then able to maintain stable temperatures in the facility to keep the ice cream adequately frozen during much of the daytime peak load period,” says SRP research engineer Alejandra Mendez.

“We have been able to shed about five hours of running conventional refrigeration off the peak load time and shift it to the nighttime operations,” Mendez says.

Such peak load shifting, especially in large industrial facilities that operate day and night, also saves SRP money in the long run.

ASU engineers (left to right) Robert Wang and Kristen Parrish discuss energy systems operations inside the 10,400-square-foot ice cream freezer with Salt River Project research engineer Alejandra Mendez and senior engineer Catherine O’Brien. Photographer: Marco-Alexis Chaira/ASU

“The more power we have to deliver during peak load times, the more we will have to purchase power elsewhere to meet that demand or eventually have to build more power plants,” Mendez says.

“The thermal energy storage technology also offers the advantage of making the overall system more sustainable and cost-effective,” Mendez adds. “With a non-mechanical, passive energy storage technology you won’t need to make expensive upgrades to an existing refrigeration system.”

The ultimate goal of the project is to determine if users’ electric bills can be adequately reduced to offset much of the installation costs of the thermal energy storage systems.

“If that’s the case,” says SRP research and development manager Hunter, “we hope to develop a customizable thermal energy storage system incentive plan to offer to customers who will implement these measures.”

ASU engineers Parrish and Wang hope to see positive signs for the system’s future capabilities once there is complete data on its performance over this year’s hot and humid summer.

The researchers expect to have sufficient data to present the project’s results to the American Society of Heating, Refrigerating and Air-Conditioning Engineers at the organization’s conference in January.

The phase change material has already allowed Bashas’ to run compressors less often during the hottest hours of the day — the peak load time when electrical power is most expensive — resulting in lower operating costs, Parrish says. She and the other ASU researchers are in the process of determining the overall energy impacts of the phase change material.

Parrish, a civil engineer, has successfully teamed with SRP in the past to improve residential energy efficiency by applying her building operations expertise and research.

The ice cream freezer project is giving Wang an opportunity to apply his varied expertise in chemical, mechanical and materials science and engineering to the energy sector.

The work is also providing a real-world research application opportunity for students. Neda Askari, who is pursuing a doctoral degree in civil, environmental and sustainable engineering — with a focus on the latter field — and Prathamesh Vartak, a materials science and engineering doctoral student, are helping to measure the efficiency of the thermal energy storage system and to model the energy and cost impacts of such systems.

Beyond the value the endeavor may yield for Bashas’ and SRP, Parrish and Wang are hoping it leads to blueprints for successfully replicating the system in a variety of other large-scale industrial freezer operations.

The project extends an almost 30-year partnership between SRP and ASU.

“We communicate about the needs we have and then once a year our staff meets with ASU people to brainstorm new projects,” says SRP engineer Mendez. “Then we match the professors with SRP’s people to tackle specific challenges.”

There are currently more than 45 collaborative research projects involving more than 30 ASU faculty members — most of them within the Fulton Schools.

Says SRP’s Hunter, “It’s great to have a place nearby where we can access all that expertise.”