Quest for microscopy advances aims to boost high-tech capabilities

ASU researcher creating new opportunities for a new era of discovery through accessible imaging methods

To discover or create something never before seen, researchers often require technology that doesn’t yet exist. An idea is only an idea until researchers can chart the path to achieve it along with the tools to test it.

While there are countless established methods and tools, innovation can emerge by adding new functionalities, optimizing design or bringing existing methods into a new context. The field of microscopy is the pinnacle of generating new context by providing images that have never been visible to the human eye.

One method for seeing beyond the capabilities of the human eye is polarimetric imaging, which analyzes how an object interacts with light at various angles and geometric planes. Contrary to how polarized sunglasses protect our eyes by restricting certain angles of light, polarimetric imaging detects light at each angle to gather as much detail as possible.

The method provides enhanced image contrast and detail to reveal structural features invisible to the human eye by analyzing the polarization state change of light interacting with objects to develop a more detailed image, making it valuable in any industry that needs to confirm or discover microscopic details. However, the standard design of polarimetric microscopes is bulky, large and hard to use outside of a laboratory setting.

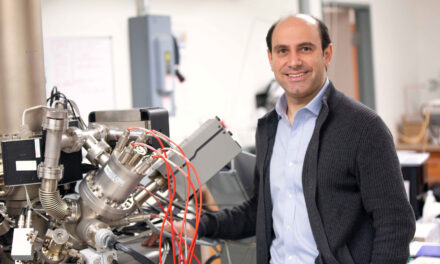

Yu Yao, an associate professor of electrical engineering in the School of Electrical, Computer and Energy Engineering, part of the Ira A. Fulton Schools of Engineering at Arizona State University, is reducing the size and complexity of polarimetric microscopes so they can be used by more industries and in other work environments beyond research laboratories.

Yao’s progress in improving microscopy has the potential to launch countless additional advancements to enable its expanded use in medicine, material and structure characterization, industrial inspection, biological study and many other fields.

Yao is now seeking collaborators from other disciplines to help incorporate her technology to find, and ultimately surpass, any prospective limitations.

“There is so much we can do,” Yao says. “We just need to prove it.”

The standard polarimetric microscope. Image courtesy of axometrics.com

Zooming in on pain points

Between designing innovative nanoscale optoelectronics and inventing chip-integrated metasurface devices, Yao’s research history demonstrates an acute understanding of optimizing function while condensing size and cost.

These advancements in polarimetric microscopy were supported by her 2021 National Science Foundation Faculty Early Career Development Program (CAREER) Award, where she

“Anyone interested in detecting the minute details of a structure has the potential to benefit from this technology,” Yao says.

The only thing standing in the way of polarimetric microscopes and their boundless applications is physically getting them out the door. The current microscopes are bulky, slow and complicated to operate due to rotating elements that rely on precise rotations and positioning for proper alignment.

“Relying on multiple moving components makes it more challenging to operate,” Yao says, “so we remade this device with the user in mind.”

To apply this method out of the lab and in new industries, Yao and her team focused on improving the system’s scalability, performance and reliability.

The filter of the sensor requires a certain level of thickness to test and analyze polarization; however, this filter is not compatible with the light and thin structures often used to integrate into cameras.

A recent paper published in the scientific journal Advanced Functional Materials titled “Metasurface-Based Mueller Matrix Microscope” revealed the findings of Yao’s team.

(Left) Yao has designed a smaller and simpler device to perform polarimetric microscopy. (Right) The polarization state analyzer, which is approximately the size of a quarter, contains the imaging sensor. Images courtesy of Yu Yao.

Yao uses nanophotonics principles by restructuring the filter into an array of microscale filters to produce an artificial high selection ratio for polarized light. The arrangement produces a strong polarization property from a thin layer of a few hundred nanometers and can be adjusted to select different types of polarization.

The researchers have circumvented the need for thick filters while inhibiting interference between adjacent areas to enhance compactness, speed and accuracy.

“We chose simple strategies to innovate the structure on a nanoscale to overcome the limitation of bulk optics, but kept it scalable and compatible with platforms used in industry,” Yao says.

Discoveries during development

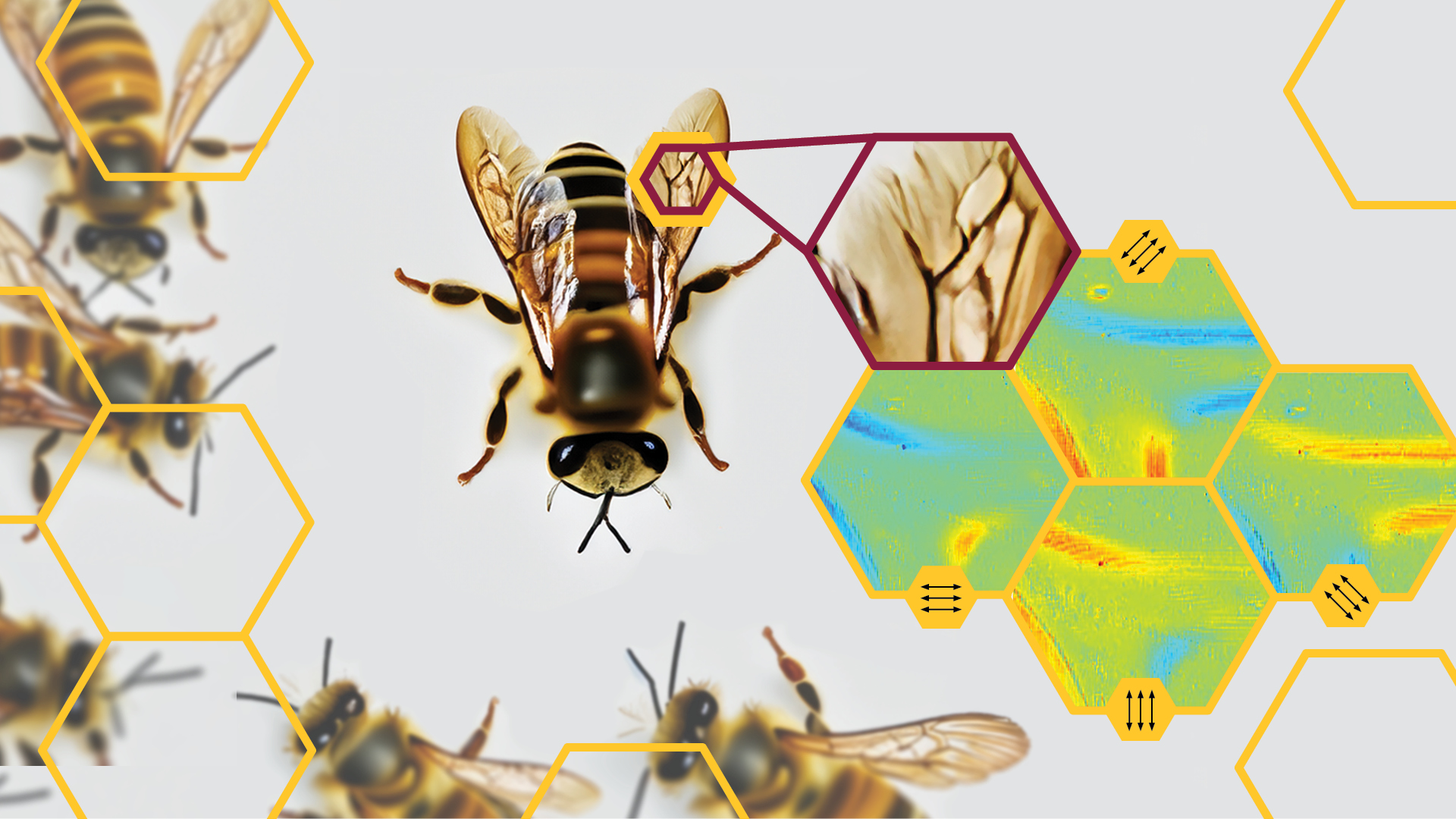

Yao and her team began testing this approach with materials they thought could work for potential future uses: honeybee wings for anatomy, silver dendritic particles for manufacturing and nanofilms for nanomaterial development.

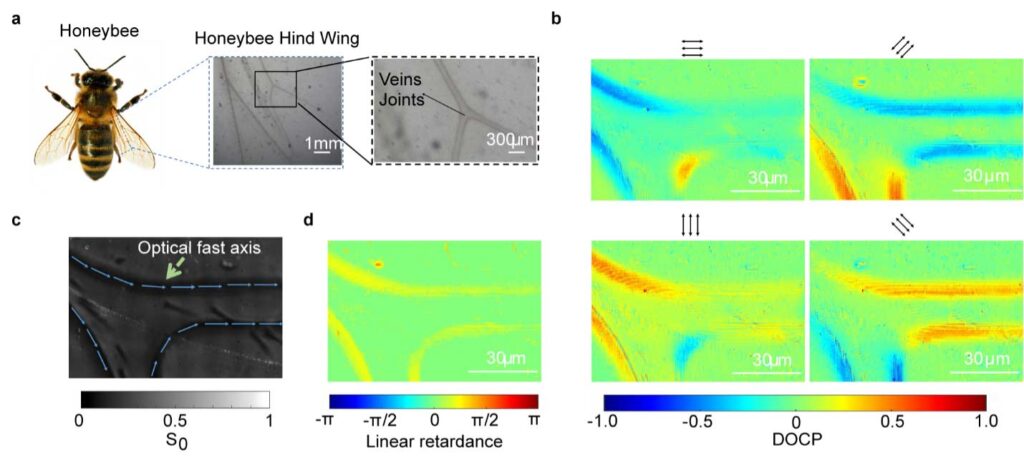

Honeybees detect the polarization of light in place of optical vision, known as polarization vision, and scientists have extensively studied how bees share information through social activities. While studying honeybee wings, Yao discovered a trait in the tissue of wing joints called linear birefringence, an optical property that manipulates the polarization state of light. This novel discovery, albeit accidental, suggests that bees might have a polarization appearance.

Full Stokes polarimetric images and Mueller matrix microscopic images of honeybee hind wings. a) Microscopic image of honeybee hind wing vein joints. b) DOCP images of honeybee vein joints with input polarized along 0°,45°,90°,135°respectively, polarization images were taken under red light illumination (wavelength range from 630 to 670 nm). c) Illustration of the optical fast axis of the honeybee wing joints. d) Linear retardance extracted from MM of honeybee wing joints under red light illumination. Images courtesy of Yu Yao.

Yao says the unexpected discovery is a testament to the microscope’s potential.

“We hadn’t planned to make a discovery in biology,” Yao admits. “But it demonstrates that we have so much to learn from examining nanostructures in any context.”

Jiawei Zuo, a senior metasurface research and development engineer at Lumotive who graduated as an electrical engineering doctoral student from Yao’s lab, says that working with Yao on metasurface optics deepened and strengthened his perspective on the revolutionary potential of metasurface optics.

“There is a burgeoning demand for the development and commercialization of compact and advanced metasurface optics for sophisticated optical solutions,” Zuo says.

She is optimistic that the method can be applied to commercial products for various procedures and is now confronting the next big question: What can’t it do?

A tool seeking a task

Yao is now on the hunt for collaborators in all areas of engineering and science to incorporate her technology into their work to meet the needs of various communities.

The team anticipates applications for semiconductor wafer manufacturing and inspection for defects in the technology. The team’s breakthrough in anatomy is matched by its potential to diagnose cancer and other diseases through tissue samples. The microscope also has agricultural implications for food and safety regulations, as well as off-world applications in telescopes, satellites and spectral object identification.

Yao says the microscope may be helpful for researchers who want to learn more about the surface morphology of the substance they’re handling.

“We found that our method picks up details for surface morphology that other researchers are looking for and I want more people to be aware of this,” she says. “What we need now is feedback on applications so we can tailor the technology to serve potential purposes better.”

The team is already working with the U.S. Department of Energy and the National Science Foundation to explore applications.

“We wanted to look forward to see what we can do in the future, and how that could help people in different application fields,” Yao says.

She foresees the technology as the vital tool that many researchers have been waiting for as technology developers race to catch up to researchers’ ideas for the new devices they need.

“We will develop this tool further to make it as accessible in any environment,” Yao says. “From monitoring production lines in a factory to examining cells in surgical rooms, polarimetric microscopy can make so many tasks easier and the application can be much broader than its current uses.”