Extended reality class prepares students for semiconductor industry

ASU researcher Umberto Celano delivers valuable engineering experiences using immersive technology

Semiconductor manufacturing is a complex and fast-changing field, driven by innovation and investment to meet growing societal demands.

For engineering students interested in joining this industry, access to hands-on experience is vital in developing skill sets and determining career pathways.

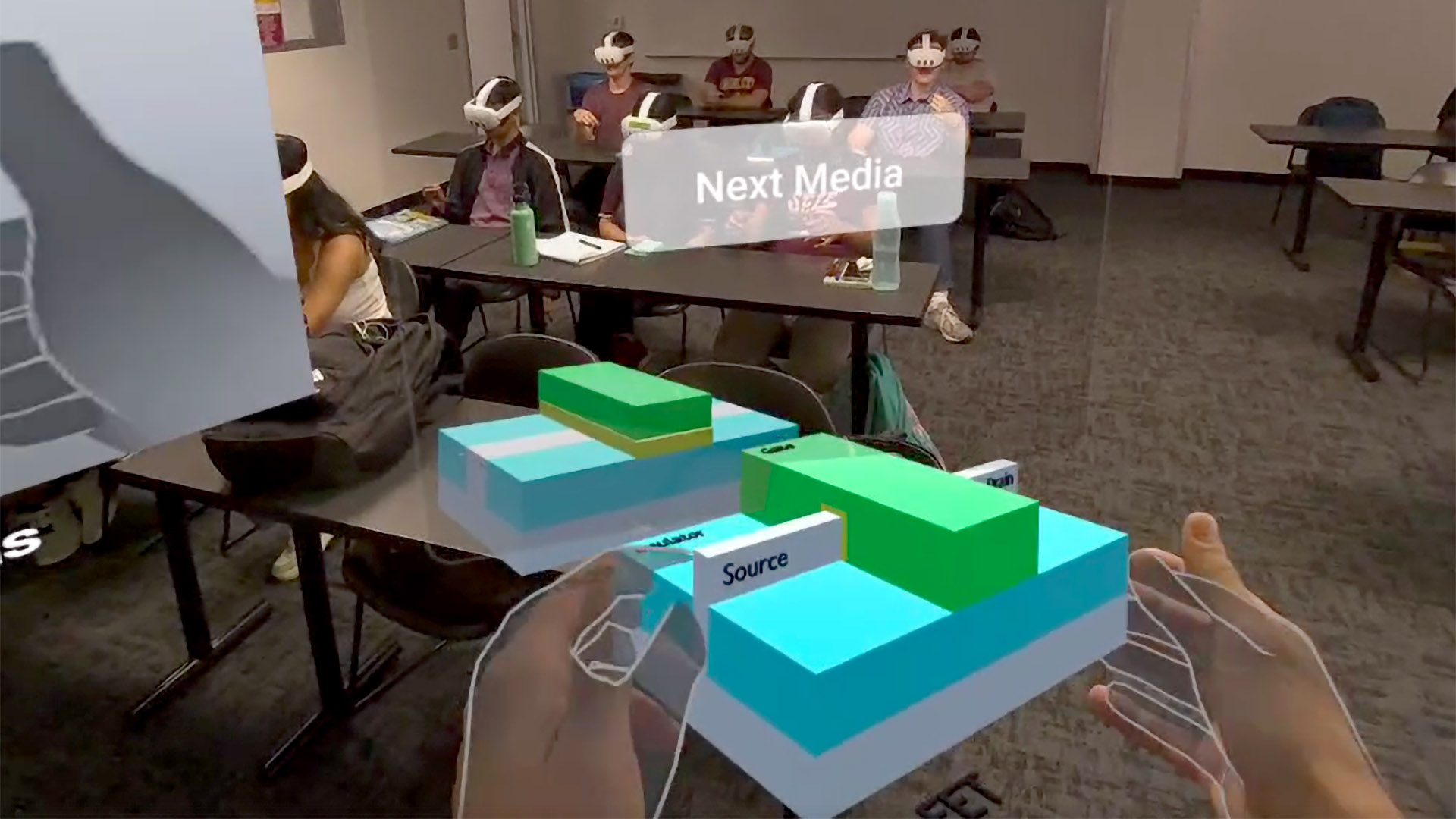

Graduate students in the Ira A. Fulton Schools of Engineering at Arizona State University interested in a semiconductor career now have an opportunity to gain new understanding of microchip production through a new extended reality, or XR, assisted course.

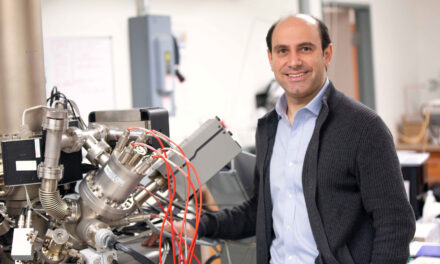

Umberto Celano, an associate professor in the School of Electrical, Computer and Energy Engineering, part of the Fulton Schools, is bridging the gap between classroom instruction and semiconductor manufacturing environments that otherwise are not easily or regularly accessible to students.

Celano’s inspiration to incorporate XR started as a passion project stemming from a need to educate students about fundamental analysis techniques used in high-volume integrated circuit, or IC, manufacturing. XR also presented an opportunity for learners across various engineering disciplines to deepen their knowledge of advanced semiconductor fabrication techniques.

“Previously, the only way to gain this experience would be to bring multiple students into a semiconductor cleanroom, and this is not always feasible,” Celano says. “An immersive experience enables us to bring realistic models of tools and large, expensive machinery into the classroom for students to examine and interact with at different scales.”

Celano began collaborating with Fulton Schools professors Robert LiKamWa and Binil Starly in 2023 to determine the best method of deployment, defining the overall narrative for the course and designing digital assets for students to ultimately interact with.

LiKamWa, an associate professor of computer engineering with a joint appointment in the School of Arts, Media and Engineering, part of the Herberger Institute for Design and the Arts, was pivotal in bringing interactive experiences to life for the course. He also directs the Meteor Studio, which explores the research and design of software and hardware for XR systems to enhance storytelling.

LiKamWa supported development of the immersive media player system, or IMPS, which serves as the platform where digital assets are uploaded for students to then explore in class.

In addition, a team of students worked with Celano to develop the concept and course deliverables. Graduate teaching assistant and doctoral student Krutik Pandya is excited to see the result of the team’s efforts and the impact it will have on engineering students.

“With the growing emphasis on the future of semiconductor fabrication, training a skilled workforce has become a top priority,” Pandya says. “Contributing to this remarkable project with an amazing team and utilizing extended reality technologies to create an immersive learning experience in semiconductor metrology reinforces my confidence that we are shaping the future.”

Metrology is the scientific study of measurement and critical to the measurement-intensive semiconductor manufacturing industry.

Beyond the novel teaching experience for students, this work supports the Southwest Advanced Prototyping Hub, or SWAP Hub, workforce development mission to accelerate the lab-to-fab transition.

Extending engineering environments into the classroom

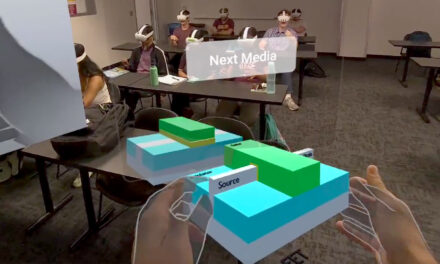

Extended reality serves as a collective term for immersive technologies, including augmented reality, or AR, and virtual reality, or VR.

Unlike a fully immersive VR experience where users are completely removed from their environment visually, the course deploys AR where learners can examine objects and models while maintaining view of their desk and even the professor. With the use of a headset, AR adds layers of virtual objects to the space that students can interact with.

The course EEE 598 Metrology for Semiconductor Devices introduces students to the key principles behind measurement methods and their underlying physics. The class covers modern techniques used in high-volume manufacturing, exploring their limits and practical applications. Additionally, students learn to apply statistical methods to analyze semiconductor materials and optimize chip production processes.

Ultimately, the course aims to provide ASU engineering students with an innovative, immersive learning experience focused on metrology and analysis for semiconductor manufacturing.

The goal of the XR technology is to help students grasp the methods and instruments used in semiconductor metrology. It also emphasizes the physics behind inspection tools used during and after semiconductor processing.

“Engineering students wanting to join this industry will benefit massively because whether they focus on a career in metrology, quality control, failure analysis or device design for example, you are getting a great overview,” Celano says. “Even if a student pivots in their career path, they will have gained a lot of foundational knowledge and common understanding critical to other teams.”

Celano hopes more students consider the course given the impactful investments and resources allocated to expanding the semiconductor manufacturing and packaging footprint in Arizona.

From challenges to opportunities

The rapid evolution of semiconductor manufacturing tools and techniques, combined with frequent updates to consumer XR headsets, presents a unique challenge for maintaining the course. With the foundation now established, the next step to ensuring a high-quality student experience is to continuously update the material to keep pace with these advancements.

“The course is a living thing because numerous mechanisms of the industry are changing quickly so we want to ensure the material is in alignment,” Celano says. “As new tools for semiconductor manufacturing are created, our task will be to prepare new assets to upload and make adjustments to improve the immersive experience.”

With the ability to showcase initial results of what is capable for instruction, Celano hopes to engage additional university partners and semiconductor companies in curriculum development to enhance the learning experience outcomes.

This new course will benefit from both student feedback and supplemental data points as it is offered more and evolves.

He envisions it as a springboard for other classes to integrate immersive teaching methods that will help prepare them for roles in the semiconductor industry.

“There are a lot of classes that can benefit from these dynamic experiences,” Celano says. “Coursework in emerging solid-state electronics, semiconductors and circuit design are courses that would be beneficial for students. However, the possibilities extend to any engineering course where you want students to interact with three-dimensional objects and environments that are not consistently accessible.”