Taking steps toward ankle rehabilitation using soft robotics

Student team wins top spot for their innovative device at wearable robotics conference

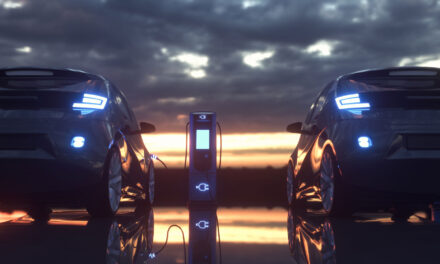

Above: A soft robotics exosuit designed to assist with rehabilitation of the foot and ankle. The project, led by Fulton Schools students Marielle Debeurre, Tiffany Hertzell and Carly Thalman along with Assistant Professor Hyunglae Lee, was awarded the top prize at the WearRA Innovation Challenge earlier this year. Photographer: Erika Gronek/ASU

Moving your foot requires flexing the muscles in your calf, ankle and the foot itself. But these seemingly simple actions can be difficult for people who develop muscle weakness or partial paralysis in their legs following a stroke (hemiparesis). The same is true for those with chronic ankle instability, often the result of a sports-related injury or neuromuscular diseases like multiple sclerosis, muscular dystrophy and amyotrophic lateral sclerosis.

To support people in recovery, three student researchers have been working to create a soft robotic ankle-foot orthosis, or SR-AFO, exosuit that assists with lower-limb gait rehabilitation. The students’ research is guided by Hyunglae Lee, an assistant professor of mechanical and aerospace engineering in the Ira A. Fulton Schools of Engineering at Arizona State University. Their project is funded by the Global Sport Institute at ASU.

Most foot braces are stiff and uncomfortable, so the team wondered if they could create a dynamic brace that constantly adjusts itself with each step. Their prototype uses two groups of soft inflatable actuators that actively adapt to the user while they are using the device. One set of actuators braces the leg while the other assists with leg push-off during motion.

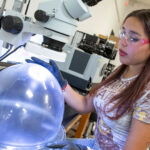

Systems engineering doctoral student Carly Thalman demonstrates the soft robotic ankle-foot orthosis exosuit during ASU Open Door 2020. Photographer: Erika Gronek/ASU

The unique design earned the top prize in the WearRA Innovation Challenge at the Wearable Robotics Association Conference 2020. Team members Marielle Debeurre, Tiffany Hertzell and Carly Thalman, as well as their advisor Lee, received $2,000 and free entry to the next WearRAcon. The win was a welcome recognition of the multidisciplinary team of students pursuing different degrees and bringing a range of experience levels to the project.

Thalman, a National Science Foundation Graduate Research Fellow, started the project during her first year as a systems engineering doctoral student in Spring 2018.

“I was introduced to the field of soft robotics in my undergraduate studies at ASU and became fascinated with the idea that robots could be designed and configured in such non-conventional methodologies,” says Thalman. “The concept that a robot could mimic features and characteristics of biological structures, or be integrated seamlessly like clothing caught my eye right away, and I have been conducting research in the field ever since.”

She began the exosuit project by developing, modeling and creating the fabric-based contracting actuator. The design was originally developed to help individuals with a condition called drop foot, an inability to lift the front part of the foot. Her fabric actuator design helped users achieve multiple degrees of freedom for ankle mobility. She went on to improve supportive actuators for lateral buckling prevention.

“After being exposed to more of the wearable robotics community and seeing ways that robotics are addressing issues with human mobility, I found motivation to see how my efforts could be dedicated to improving the quality of life for others,” says Thalman, who has family members and close friends who have had strokes or overcome major ankle injuries and impairments. “Seeing their struggles and challenges during and after recovery showed me just how much work still needs to be done in this field to address ongoing issues for those in rehabilitation and recovery from ankle and gait impairments.”

Hertzell, a recent mechanical engineering graduate, worked on the project as part of the Fulton Undergraduate Research Initiative. She says that she learned from Thalman how versatile and effective soft robotic solutions are.

“Traditional rigid robotic solutions can achieve the necessary motions to assist humans, but soft robotics can achieve the same motions in a more innovative way,” says Hertzell. “Soft robotics are more innovative because they are lighter weight, comfortable for the user, inexpensive and can still achieve the motions and force outputs of rigid robotics.”

Debeurre joined Thalman on the project in Spring 2020 while pursuing a master’s degree in mechanical engineering. She brought with her the experience she’d gained as an undergraduate researcher, for which she was named a Spring 2019 Fulton Schools Outstanding Graduate.

“It became a passion of mine to develop something that assists people in particular,” says Debeurre, who is now a doctoral student at École Nationale Supérieure d’Arts et Métiers in France. “Engineers are always talking about solving the world’s problems, and, while that is undoubtedly just in itself, work tends to feel the most rewarding when you see the improvement of the people you’ve helped.”

Future directions for this project involve investigating more advanced methods of gait detection to allow the SR-AFO to easily adapt to the needs of the user. Examples include assisting the ankle in various directions for increased support and encouraging fast, more fluid walking patterns. The idea is the SR-AFO can easily adapt to any type of impairment with little adjustment, and can be comfortably worn during rehabilitation similar to a piece of clothing.

“It only takes a short time for someone to realize just how extraordinary the field of soft robotics is,” says Debeurre. “Scientists, mathematicians and engineers spent all of human history trying to make technology more complex, but soft robotics prove that you can achieve comparable functionality with greater simplicity. The ingenuity and the technological achievements are still there, and due to the materials and simplicity of soft robots, we are able to design and manufacture the SR-AFO for a fraction of the cost of some rigid exoskeletons, and still see benefits for the user.”

Thalman was a finalist in the WearRAcon Innovation Challenge in 2019 and says this year’s competition was an amazing opportunity to return and get additional first-hand experience working with others in the wearable robotics field.

“Participating this year has allowed us to connect more with the wearable robotics community and get valuable feedback on how to proceed,” she says. “It also has provided us with much-needed funding for equipment, materials and supplies.”

Thalman credits much of the team’s success to Lee, her doctoral advisor.

“It has been such an inspiration for me to work with him, seeing how he is able to motivate and ignite passion in the students in his lab, and create a culture of respect, integrity and collaboration,” she says.

The team — comprised of an undergraduate, a master’s-level and a doctoral student — pooled their talent and experience to learn from each other, exhibit excellent teamwork and achieve great things, like winning first place in a global competition in a very short time.

“All of the team members are really smart, very creative, extremely hardworking and I really enjoyed every moment of mentoring,” says Lee. “The way they work together and help each other has also become a very good example for others in our lab.”