ASU and Siemens amplify curriculum for industry-bound students

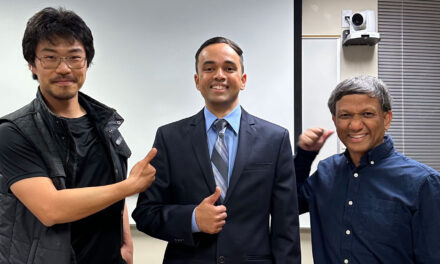

Above: Engineering senior Jean-Francois Enriquez is using Siemens hardware to operate a digital twin machine as part of his senior design capstone project. Photographer: Sona Srinarayana/ASU

Global technology leader Siemens is one of the driving forces behind engineering workforce development in the Phoenix area. The company’s support of Arizona State University’s eProjects program is helping to propel engineering student readiness at The Polytechnic School, one of the six Ira A. Fulton Schools of Engineering at ASU.

For nearly 10 years, the eProjects program at The Polytechnic School has facilitated industry and student collaborations, allowing both groups to work together on real-world projects to develop or improve a product or process to broadly advance engineering capabilities.

Through this mutually beneficial partnership, industry-bound students gain applicable workforce skills and technical knowledge while industry partners gain innovative engineering solutions, intellectual property for operational implementation and opportunities for recruitment.

“This program is successful because industry partners challenge and guide our seniors through tangible engineering demands and share their experience and wisdom along the way,” says Tim Beatty, associate director of the eProjects program. “It helps transition our students into contributing industry professionals — the engineers of tomorrow — and there is nothing more important than that in today’s world.”

Siemens has amplified the eProjects program by offering students an opportunity to become certified in the company’s industry-grade systems.

“Our software and hardware is used by leading companies of various industries all over the world,” says Mia Fujii, a portfolio development executive for Siemens Digital Industries Software. “Certifying ASU students would give them a leg up when applying for jobs in Arizona’s growing manufacturing industry and beyond.”

Senior design group explores digital twin technology

Engineering majors Jean-Francois Enriquez, Dakota Mathews and Kenneth Alarcon Aguirre chose Siemens as their industry partner for their senior design project partly because of Siemens’ leadership in digitalization technology.

The team excelled in their two-semester project, which was focused on assembling and testing a digital duplicate of an existing physical machine, which is known as digital twin technology. This approach can be used to optimize production line components, process flows and improve throughput.

Using the Internet of Things for replication, digital twins are used in various industries to increase efficiency, advance operations and reduce risk, offering a test bed before application in the real world.

Ryan Klenner, a business development manager for Lightworks, a unit of ASU’s Global Institute of Sustainability and Innovation, views the capstone project experience as a way to amplify the strengths of both students and industry experts and looks forward to how Siemens will use the students’ technology to advance the energy industry.

“Digital twin technology enables humans to do things we weren’t able to do before, opening up a whole new world of possibilities,” Klenner says.

Enriquez, who is now a mechanical systems engineering graduate, says he found the project to be a valuable learning experience. He was recently hired by Siemens as an associate consultant for his exceptional work on this project.

“For months prior, I had only been working on the digital version of this machine, so I remember being so surprised and satisfied when the [physical] machine was running almost exactly how it did on the virtual version,” Enriquez says. “It showed the culmination of months of hard work amounting to that moment and it also showed me, in person, what digital twin technology is all about.”

Fujii says she believes that the reason the project was successful was because the ASU student team was committed to learning new skills and receiving mentorship virtually.

“They completely knocked our socks off with how quickly they learned to design and build a full digital twin using Mechatronics Concept Designer in NX software and Siemens TIA Portal,” she says. “This is not simple stuff, it’s a real application and they not only learned it, they learned it fast!”

The senior design team continued to impress at live presentations to both ASU and Siemens, including an executive-level synopsis of the project and a real-time demonstration of their digital twin in action.

Jerry Gintz, an engineering senior lecturer at The Polytechnic School and the team’s faculty advisor, supported the students as they ventured into new territory.

“The digital twin project was the perfect foundation for students to exploit Industry 4.0 technology to establish a platform for learning and optimizing automated manufacturing processes,” Gintz says. “Ultimately, the project will be replicated to augment hands-on learning for the industrial automation sequence of graduate and undergraduate engineering courses. This project couples nicely with our current educational focus on leveraging technology to help reshore American manufacturing.”

A shared vision prepares students for high-demand industries

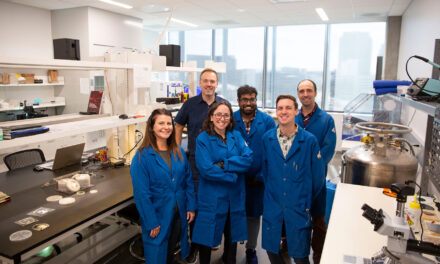

In March, ASU was awarded the One Workforce grant, an $8 million grant from the U.S. Department of Labor to lead an initiative that would train workers for high-paying, high-demand jobs in manufacturing, cybersecurity and information technology.

The One Workforce grant will help restore a critical skills shortage in the U.S. by establishing the Arizona Workforce Training Accelerator Partnership for Next Generation Jobs, or AZNext, a program led by various ASU schools including the Fulton Schools and external partners.

“Siemens was one of the companies that provided a letter of support prior to the submission of this proposal, which aligns with ASU’s vision of offering substantial tools to prepare students for the workforce and expanding the manufacturing presence in Arizona,” says Beatty, who leads the eProjects senior design project program. “Their support bolstered our chances of getting the grant.”

Siemens is a member of the AZNext advanced manufacturing advisory board.

“We will continue to invest in ASU and the next generation of engineers,” says Gerald Deren, executive director for academic enablement at Siemens Digital Industries Software. “We believe that today’s engineers need to be ready to tackle the world’s challenges.”

Similarly, the eProjects program will continue to prioritize student preparedness and the program organizers will ramp up its breadth to benefit both students and the manufacturing industry on a broader scale. Enriquez’s example is just one of the many successful academic-to-industry transitions.

He will begin his journey at Siemens by becoming acquainted with the foundational concepts of customer projects. His intensive training introduction will include how-to topics that range from soft skills and customer-facing projects to implementation.

Looking back, Enriquez says, “I believe that the skills I have gained and presented through this project have helped me attain this great opportunity.”