ASU Air Devils fly high at aircraft design competition

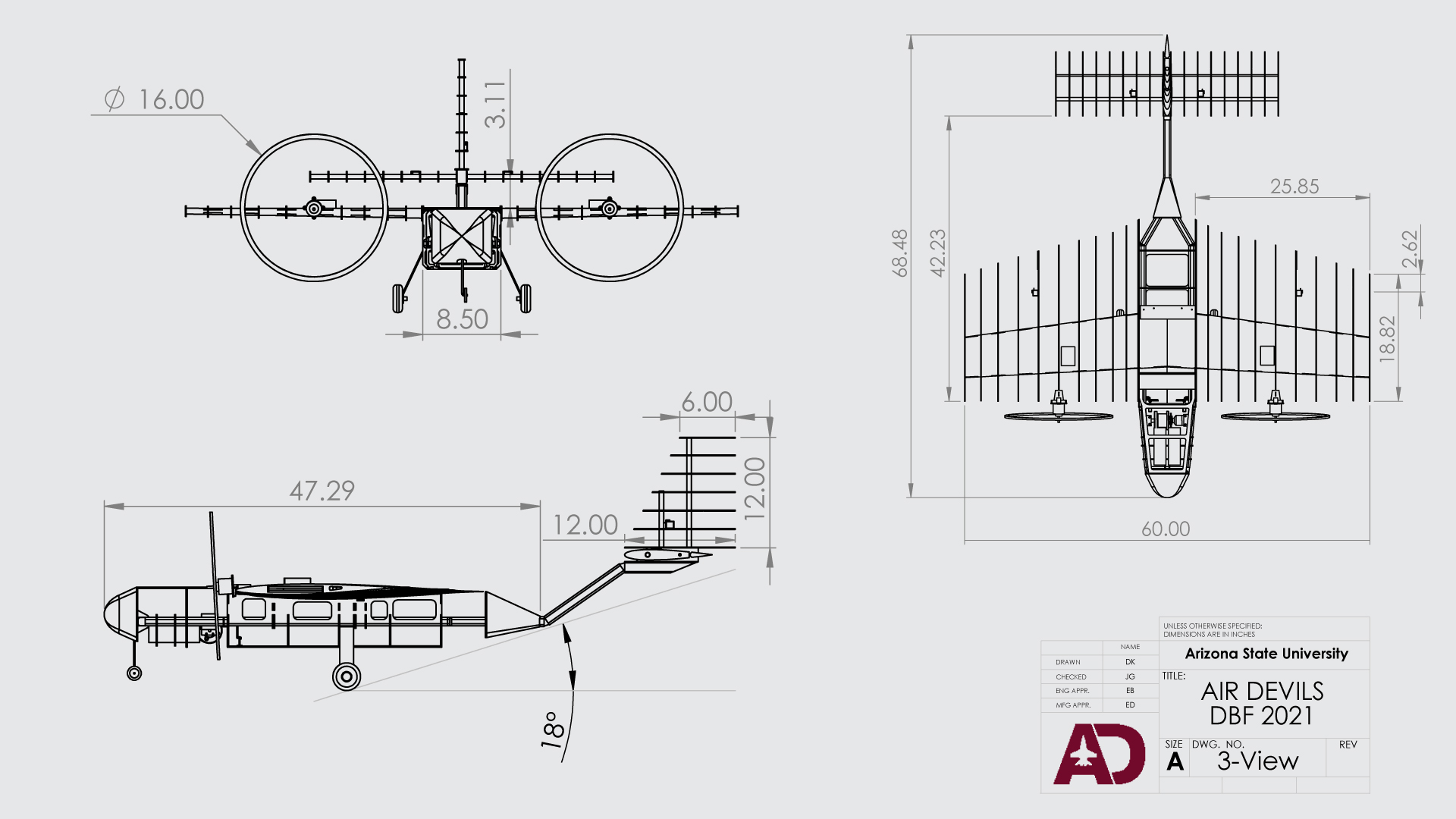

Above: The Air Devils student organization at Arizona State University earned 14th place at the international 2020-2021 American Institute of Aeronautics and Astronautics Design/Build/Fly competition. The team was challenged to design a remote-controlled aircraft that could deploy and retract a towed sensor in flight. Graphics courtesy of Air Devils

Duct tape usually comes into play when something isn’t working as intended. But for Arizona State University engineering students competing in the American Institute of Aeronautics and Astronautics Design/Build/Fly competition, it signifies the team’s well-designed aircraft that flew on the first try.

Duct Tape Overcast — an aircraft that is “built like a steakhouse but handles like a bistro,” according to Air Devils student organization president Daniel Kosednar — flew the team to a career-high 14th place finish during a bumpy 2020-2021 competition year.

AIAA DBF, sponsored by Raytheon Missiles and Defense, challenges undergraduate and graduate students from universities around the world to apply their skills in a real-world aircraft design experience. The Air Devils team from the Ira A. Fulton Schools of Engineering at ASU was one of 115 teams invited to create a small, unmanned, radio-controlled electric aircraft for the competition.

Each aircraft must meet strict requirements and complete flight missions that change from year to year, requiring a new design and build for each competition. This year’s challenge was to design, build and fly an aircraft with a towed sensor that must complete missions to deploy, operate and recover the sensor.

“I’m very happy with Air Devils once again placing deep in the upper quartile of teams,” says Timothy Takahashi, a professor of practice of aerospace engineering in the School for Engineering of Matter, Transport and Energy, one of the six Fulton Schools, who advises the Air Devils student organization. “We were very happy that we placed ahead of a number of historically strong teams, notably our Pac-12 rivals at the University of Southern California.”

Air Devils team members (left to right): Students Zachary Norris, Max Stauffer, Daniel Kosednar, Kevin O’Brian, Jack Griffin, Evan Draganchuk and Professor of Practice Timothy Takashi. The Air Devils team poses with Duct Tape Overcast, the aircraft the team built for the 2020-2021 American Institute of Aeronautics and Astronautics Design/Build/Fly competition. The aircraft’s name is inspired by the World War II B-17 Flying Fortress aircraft named Aluminum Overcast that still flies today. Photo courtesy of Timothy Takahashi

Overcoming challenges

Along with Kosednar, an aerospace engineering senior, the team includes propulsion designer Maxwell Stauffer, an aerospace engineering senior; stability and control designer Kevin O’Brien, an aerospace engineering senior; subsystems designer Jack Griffin, now an aerospace engineering graduate student at ASU; structures designer Ivan Pesqueira, a mechanical engineering senior; and electrical systems designer Nitish Chennjou, a computer science sophomore.

Among the team members who graduated this past spring were pilot and chief builder Evan Draganchuk, who recently completed his bachelor’s degree in aeronautical management technology with a focus on unmanned aerial systems; and wing designers Evan Barker and Derek Stratton, who both graduated with their bachelor’s degrees in aerospace engineering.

All nine of the Air Devils team members had competed before in the Design/Build/Fly competition. However, this year posed new challenges as distancing requirements made the work more difficult throughout the COVID-19 pandemic.

“We had to completely change how we ran meetings and designed the aircraft,” Kosednar says. “Our computer-aided design model was one of those key areas.”

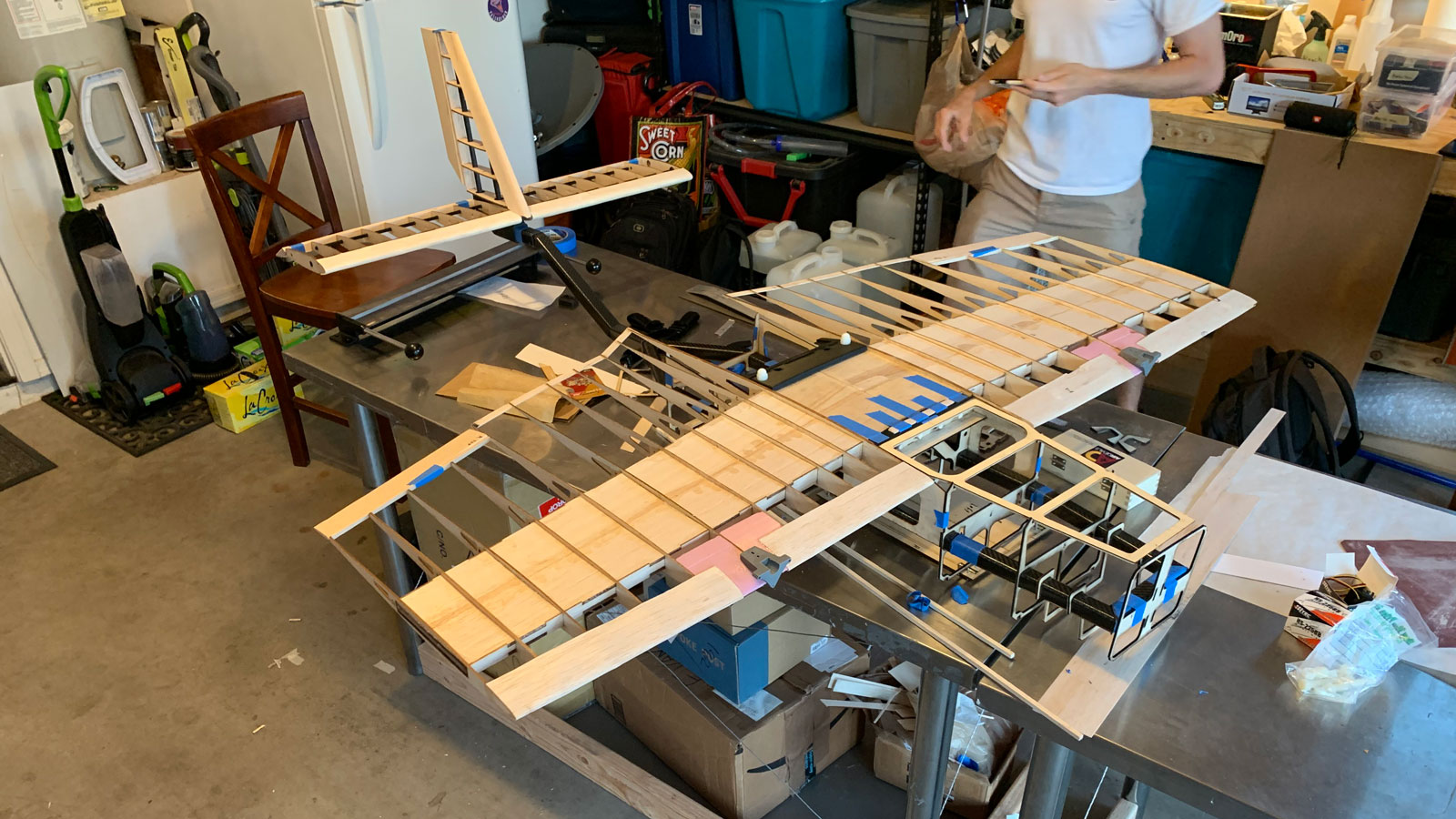

The team used CAD digital models in previous competitions, but relied more on physical prototyping and iterating on the design as they went.

“But this year we only had the time to build one aircraft,” Kosednar says. “So, all the work done virtually was critical to catch errors and clashes before we started construction.”

The Air Devils team members worked together virtually to design and refine Duct Tape Overcast digitally so when they were able to get together and build, it worked on the first try. The team used 3D printing and laser cutting techniques to create the aircraft. Photo courtesy of Daniel Kosednar

The team encountered several design challenges along the way, including space constraints, manufacturing concerns and reliability, especially in the design of the retractable sensor component.

In their most challenging mission, the team had to lower a sensor contained within the body of the aircraft on a tether and tow it for 10 minutes. The team created a winch mechanism to lower and raise the sensor from the “bomb bay” compartment.

“Making sure the sensor deployed, flew with stability and retracted reliably was my number one goal for this aircraft,” Kosednar says. “When we got that system to work in flight, it was one of the highlights of this year’s competition.”

Air Devils also set themselves apart from the other teams with Duct Tape Overcast’s complex wing design.

“What’s unique about our aircraft is that it has a complex custom wing designed for optimal flying qualities and efficiencies,” Kosednar says. “Most other teams use a simple constant airfoil ‘Hershey bar,’” or a standard rectangular wing.

According to Griffin, the team’s well-developed design skills were key to their biggest success.

“In our first test flight, our plane flew perfectly and did so just how the numbers said it should fly,” Griffin says.

Watch the Air Devils’ AIAA DBF video, which earned the top score for the competition, to learn more about the design of the aircraft and the missions it completed. Video by the Air Devils team

Putting their work to the test

AIAA’s in-person flyoff event in Tucson, Arizona, was canceled due to the pandemic, so instead teams flew their aircraft at their home locations and submitted recorded videos of the flights. Typically the in-person event is a highlight of the competition for many participants, but they were still able to see their peers’ work and by connecting virtually.

Each team tackled the design challenges in unique ways — Kosednar particularly liked the Ohio State University’s design for their Maverick aircraft (all video submissions can be viewed on the 2021 AIAA Design/Build/Fly YouTube playlist).

Kosednar says he enjoys the creativity that aerospace engineering allows for solving complex challenges, an aspect that was on display from the teams who participated in AIAA DBF.

“There are dozens of unique solutions to the challenges we were presented, each resulting in a totally different plane, and each formulated by a dedicated team just like us,” Kosednar says.

Griffin adds, “It is always cool to see a design we did not choose or something we never thought of flying. It makes us think, ‘Wow, I can’t believe they made that work,’ or ‘Ah! I wish we thought of that.’”

A 14th place standing means the Air Devils aren’t finished with the competition, and the team members who are still ASU students are eager to participate again.

After a successful flight and executing the missions, the team is on the right track to continue to climb in the ranks. However, they had a middling score for the required design report, so the students will be working to hone their technical writing in addition to their engineering skills.

“There are dozens of small details that make the difference between an aircraft that performs and one that excels,” Kosednar says. “I’m proud of how the team incorporated lessons learned in previous years’ competitions into this year’s aircraft. I can’t wait to see what they do next year.”

Duct Tape Overcast at a scenic spot on the ASU Polytechnic campus. Lessons learned from this year’s design will help Air Devils at the next AIAA Design/Build/Fly competition. Photo courtesy of Daniel Kosednar

Building critical skills

The AIAA DBF competition is a valuable opportunity for students to apply skills they learn in the classroom.

“We’re using both math directly out of the textbook and industry knowledge passed down as well as other important literature not circulated in classes,” Griffin says. “You really can’t get a more accurate facsimile of real aircraft production anywhere else outside of industry.”

These unique, relevant experiences outside of typical school projects are also great resume-builders. Both Griffin and Kosednar secured internships based on the experience they gained in Air Devils and AIAA DBF.

“Being in a club like Air Devils that competes in competitions like the AIAA DBF is how you gain practical engineering experience, whether that be the tools like CAD and manufacturing or non-technical aspects like effective teamwork, public speaking and work ethic,” Kosednar says. “The experiences I gained in the DBF competition helped me gain my dream internship, and, hopefully, a job, with Lockheed Martin in the conceptual design group, where I get to formulate solutions to the same problems, just at a much larger scale.”

A research foundation for club success

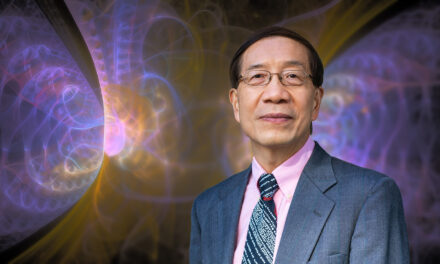

Professor of Practice Timothy Takahashi doesn’t only advise the Air Devils student organization. He also mentors students in flight-related research through the Fulton Undergraduate Research Initiative, known as FURI.

“I augment club activities with specifically targeted FURI projects, which gather fundamental data useful in the execution of any particular design,” he says. “The FURI projects helped train students to do some pretty sophisticated testing and get a good practical database of how off-the-shelf motors and building materials work in the real world.”

In the last few years, five Air Devils team members have worked on FURI projects.

Aerospace engineering senior Max Stauffer studied how to measure the thrust of an engine from in-flight instrumentation.

Another aerospace engineering senior Kevin O’Brien learned how to build an airplane that is stable in smooth and turbulent air by refining aerodynamic configuration.

Ivan Pesqueira, a mechanical engineering senior, conducted an experiment to test the strength of carbon fiber tubes for supporting unmanned aircraft.

Aerospace engineering graduate student Jack Griffin researched computational methods for structural design as a senior undergraduate student.

And Nitish Chennjou, a computer science sophomore, developed a flight instrumentation system.

“With five independent FURI projects working the fundamentals, the team really did a great job putting a design together, harmoniously merging aerodynamics, propulsion and structural design in an absolutely crazy environment,” Takahashi says.

With FURI projects spanning the academic terms in 2020 and the spring of 2021 and facing social distancing conditions, it was a difficult time to be working on research and their competition aircraft.

“Nitish was remote in California and would regularly mail his custom-designed electronics circuits and embedded controllers to and from the teams,” Takahashi says. “Even the Arizona-based team was not physically co-located.”

Past Air Devils president Nikolay Kolesov, an aerospace engineering major who graduated in 2019 and is now pursuing an aerospace engineering master’s degree at the Georgia Institute of Technology, built tools for modeling an aircraft wing structure that was the basis for the 2020-2021 design.

“These FURI projects of the past become footstones to a successful design, allowing us to build on prior arts,” Griffin says.

With this behind-the-scenes work through other Fulton Schools programs, Takahashi says he can run the Air Devils organization “as a coach with a light touch” and credits Daniel Kosednar, the team’s president, for leading the team to success during the pandemic.

Daniel Kosednar (right) — joined by Fulton Schools alumnus and Ira A. Fulton’s grandson Brian Nichols (left) and former Air Devils member and FURI researcher Jack Barker (center) — presents a Spring 2019 Fulton Undergraduate Research Initiative project in which he investigated data-enabled dynamic thrust measurements with Professor of Practice Timothy Takahashi. Takahashi mentors Air Devils team members in research projects that contribute to their aircraft designs for competitions like AIAA Design/Build/Fly. Photographer: Erika Gronek/ASU