Single-use or reusable cups? New project seeks answers

ASU researchers collaborate with Yum! Brands to explore sustainable solutions

Arizona State University researchers are collaborating with Yum! Brands on a joint research project to assess and better understand circular economy strategies that aim to replace single-use cups with reusable ones across the quick-service restaurant, or QSR, industry.

A circular economy focuses on the reuse and regeneration of materials or products as a means of sustainably continuing production. ASU’s commitment to sustainability has led to its No. 1 ranking in the United States and No. 2 in the world for sustainable practices by the Association for the Advancement of Sustainability in Higher Education.

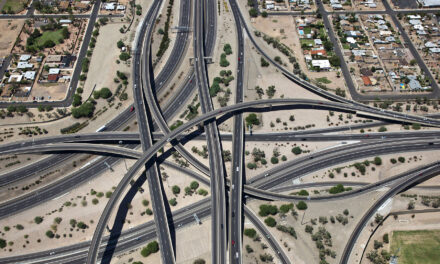

That reputation makes ASU an ideal collaborator for Yum!, a company committed to exploring sustainable packaging solutions for its more than 60,000 system-wide restaurants operating in over 155 countries and territories and serving more than 1 million customers daily.

“We’re proud to collaborate with Arizona State University on research that’s focused on the circular economy,” says Jon Hixson, chief sustainability officer and vice president of government affairs for Yum! Brands. “Partnering with a renowned institution like ASU strengthens our knowledge base and helps us better understand the role reusable packaging could play moving forward.”

Dwarak Ravikumar, an assistant professor of civil, environmental and sustainable engineering in the School of Sustainable Engineering and the Built Environment, part of the Ira A. Fulton Schools of Engineering at ASU, leads and guides this joint research project with Dileep Nakka, an associate research technologist in the Fulton Schools. Ravikumar’s work focuses on designing and implementing circular economy solutions and developing assessment methods to guide and improve the sustainability outcomes of large-scale technology transitions.

“Circular economy solutions have the potential to improve the sustainability of operations for many different stakeholders within QSR’s value chain, including cup manufacturers and distributors, reverse logistics providers and the restaurant teams,” Ravikumar says. “It makes sense that a company like Yum! would want to better understand those impacts.”

The project also highlights similarities in ASU’s and Yum!’s sustainable packaging goals. Both organizations have set goals to improve packaging, find solutions to divert packaging waste from landfills and identify ways of increasing the use of reusable alternatives.

“We are committed to making progress across our global citizenship and sustainability agenda, with sustainable packaging being a priority focus area,” Hixson says. “At Yum!, we know how important it is to collaborate on sustainability solutions which is why I am excited about this new partnership and the future learnings.”

Project focus

The project’s data and findings will help identify key differences between single-use and reusable packaging systems and evaluate the associated implications for factors such as infrastructure.

“We are seeking to understand the conditions under which replacing single-use cups with reusable ones reduces waste and the associated environmental and climate burdens of repeated manufacture and downstream, post-consumer disposal,” Ravikumar says. “This is especially important as the QSR industry continues to see growing customer demand for beverages.”

As part of Yum!’s commitment to sustainability, this study will help inform the company as it continues work to reduce its overall waste footprint through initiatives targeting packaging reduction, increasing recycled content, improving recoverability and supporting recycling systems.

“The collaboration between Yum! Brands and our school exemplifies the transformative power of partnerships in advancing sustainable practices across industries,” says Ram Pendyala, director of the School of Sustainable Engineering and the Built Environment and a Fulton Schools professor of civil, environmental and sustainable engineering. “Tackling critical challenges like reducing single-use plastics and fostering circular economies not only aligns with our school’s mission, but also reflects Yum!’s commitment to global environmental stewardship. Together, we are paving the way for innovative solutions that will shape a more sustainable future for the food industry and beyond.”

Some studies have found no clear environmental benefit to replacing single-use cups with reusable cups, but Ravikumar says this study will have a more holistic approach with assumptions and modeling to quantify and compare the environmental performance of single-use and reusable cups.

“Our project will work to identify the root causes for these inconsistencies in previous studies and resolve them by developing a robust and consistent approach to compare the environmental performance of single-use and reusable cups,” Ravikumar says. “We hope to share the findings from this research through conferences, industry white papers and reports for stakeholders later this year.”

Challenges identified from prior research

“Prior research has identified some of the challenges associated with single-use versus reusable cup systems,” Ravikumar says.

Manufacturing a single-use cup typically has a lower environmental burden than a reusable cup. It does not require post-use washing, eliminating the transportation from the store to the washing center and back after every use or back-of-house washing.

In contrast, a reusable cup offers an environmental benefit every time it is reused by diverting the equivalent single-use cup from landfill. However, reuse comes with the increased cost of manufacturing, transportation and washing, so determining how many times a reusable cup needs to be used is key if reuse is to be considered environmentally preferable. This introduces the logistical challenges associated with customer and restaurant team member education as well as understanding effective strategies to incentivize certain behaviors.

Additionally, the restaurant and beverage industries can work toward adopting industry-wide standards to share data on the manufacturing of single-use cups and reusable cups and use and purchase patterns by customers.

“Sharing data without compromising on the commercially sensitive nature of it is vital for the research and development community, including universities, to conduct robust assessments and will accelerate the development and adoption of industry standards,” Ravikumar says.

What’s next

In collaborating with ASU, Yum! underscores its commitment to resolving the challenges and inconsistencies associated with evaluating the environmental impact of single-use and reusable cups.

“This [research] will lay the foundation for developing robust industry-wide standards for measuring the environmental performance of single-use and reusable cups and identifying the most environmentally effective pathways to pursue a circular economy,” Ravikumar says.