Garbage into gold: Circular economy research makes plastic more sustainable

A National Science Foundation Emerging Frontiers in Research and Innovation project seeks to develop a circular economy that diverts plastic waste from landfills

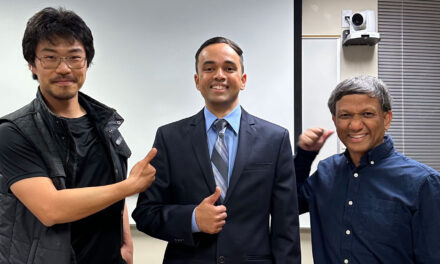

Above: Arizona State University Professor Timothy Long works with students in the ASU Biodesign Center for Sustainable Macromolecular Materials and Manufacturing, which he directs. Long is leading a team of interdisciplinary scientists and engineers from ASU, Virginia Tech, adidas, the National Renewable Energy Laboratory and Oak Ridge National Laboratory to turn waste polyurethane foams into valuable materials and products. Photographer: Andy DeLisle/ASU

Since the 1950s, plastics have changed our lives. But these amazing materials are mostly made of fossil hydrocarbons like oil, gas and coal — and none are biodegradable. So, the vast majority of the 18 trillion pounds of plastic ever produced is now trash in landfills and oceans.

While plastic recycling efforts began in the 1980s in the United States, as of 2018, the overall domestic rate of plastics recycling is only 8.7%.

“Sustainability of plastics remains a huge challenge; it’s a looming national and global crisis,” says Timothy Long, a professor in the Ira A. Fulton Schools of Engineering and the School of Molecular Sciences at Arizona State University. “It’s coming to the forefront now for people to address. There is a sense of urgency now.”

One way to reduce the challenge of plastic waste is to introduce circularity: the notion that everything created is returned to the manufacturing system with nothing sent to the landfill.

“It’s the idea that garbage becomes gold,” Long says, who also directs the Biodesign Center for Sustainable Macromolecular Materials and Manufacturing. “How do we take these waste streams of plastic and spring them back to a feedstock that’s valuable? Right now, that is a really important area for research, not only for universities but for all the leading industries that manufacture plastics.”

Developing a viable plan for a circular plastics economy is the key focus of a National Science Foundation Emerging Frontiers in Research and Innovation, or EFRI, project Long is leading with an interdisciplinary team of researchers. This team includes ASU and Virginia Tech — two early university members of the Ellen MacArthur Foundation, a global hub and leader of advances to circular economies — in addition to National Renewable Energy Laboratory, Oak Ridge National Laboratory and adidas.

EFRI projects are chosen for advancing transformative ideas that can shift knowledge and make long-term impacts on grand challenges or other societal needs.

“The ideas are novel, the engineering is challenging and the team is the right one to solve it. I think that’s a big part of the reason that we were chosen,” Long says. “We’re approaching not only the science and engineering but the humanistic elements of the technology.”

Long and his team of researchers are working to eliminate end-of-life plastics in their $1.89 million EFRI project’s “molecules to manufacturing” approach to optimize and standardize processes to make a circular economy for at least one type of plastic: polyurethane foams, or PUFs.

Graduate Research Assistants Ren Bean (left) and Jose Sintas (right) discuss monomers depicted as chemical structures in the ASU Biodesign Center for Sustainable Macromolecular Materials and Manufacturing. Timothy Long and other researchers will investigate these monomers as part of the National Science Foundation Emerging Frontiers in Research and Innovation project. Combining molecular science and engineering expertise is important to synthesize new monomers that will help improve the functionality and performance of polymers used in many plastics. Photographer: Andy DeLisle/ASU

Bringing new life to foam waste

Long and the other researchers are planning to literally go to the mattresses in the fight against plastic waste. The main polyurethane component in mattress foam represents the sixth largest family of polymers manufactured in the world; mattresses may present easier paths to collection than other foam sources, which include sneakers, seat cushions and insulation.

At ASU, Long is relying on a team of scientists from the ASU Biodesign Institute and the School of Molecular Sciences as well as engineers from the School for Engineering of Matter, Transport and Energy and The Polytechnic School, two of the seven Fulton Schools.

“The interdisciplinary culture that exists at ASU is really critical for this project,” he says.

Long’s research group of chemists and materials scientists and engineers is going back to basics and looking at how PUFs are made and exploring their molecular structure.

While Long and his team are getting down to the molecular level, Kailong Jin, an assistant professor of chemical engineering, and his research group are creating a new solvent-free process that turns PUFs directly into other polymers using enzymatic catalysts.

“If successful, this research will develop a scalable approach to recycle crosslinked polyurethane waste into a library of valuable polymeric products,” Jin says.

Meanwhile, Matthew Green, an associate professor of chemical engineering, and his research team are on what he calls “clean-up duty.”

“Taking a polymer apart does not mean you have created a circular plastic economy. You have to demonstrate that you can get those molecules back, in high purity, and use them again and again,” Green says. “My job is to try to isolate and purify the components of the stream exiting their deconstruction process, and do it in a very energy-efficient manner.”

Kenan Song, an assistant professor of mechanical engineering, is exploring how to use advanced manufacturing techniques to process waste foams, from traditional molding to new additive manufacturing technologies.

“We are developing new manufacturing principles that will innovate the porous microstructure of foams for better performance in recycled products,” Song says about his research team in the Advanced Materials Advanced Manufacturing Laboratory. “Using additive manufacturing means we will save materials and energy consumption compared to conventional subtractive processing.”

The ASU teams’ efforts are backed by two national laboratories, which “bring some of the most cutting-edge research tools that we have in the country and they bring critical national expertise to the equation,” Long says.

Oak Ridge National Laboratory contributes analytical tools to help the researchers understand and measure the fundamental mechanics of how foams can be deconstructed and reutilized.

The National Renewable Energy Laboratory brings expertise in chemical processes, reactor design and purification strategies to help break down the polymers in PUFs in a process called depolymerization.

The economic and social side of recycling technology

This research goes well beyond the science and engineering of polyurethanes. Jennifer Russell, an assistant professor of sustainable biomaterials at Virginia Tech, and her research team are making sure the technologies developed by the ASU researchers can actually be adopted out in the world. This involves considering the economic, social and environmental implications of creating a circular system for PUFs.

Russell’s team will analyze waste PUF materials from industry, commercial, institutional and residential sources — and confirm whether mattresses, versus sneakers or another source, present more significant waste management challenges and the best feedstock for recycling.

The environmental impact at each stage of the PUF life cycle is another important consideration for Russell’s team. They’ll be assessing if diverting PUF products and waste and recycling them leads to the desired environmental impact reductions.

“We don’t want to propose new technologies or new systems that leave us in a worsened environmental situation,” she says.

Techno-economic assessment will help Russell’s team evaluate the economic performance of new technologies developed by ASU researchers, the infrastructure and systems needed to divert and recycle PUFs, and the economic gains companies could see from using recycled PUF materials instead of new.

Russell’s team will also create qualitative and quantitative forecasts of future conditions and material needs with relevant stakeholders that represent management, manufacturing, government and industry “to ensure the infrastructure and systems solutions developed through this project are actually viable, appropriate and have been envisioned collectively.”

adidas, a leading manufacturer of polyurethane-based textiles, including PUFs for use in athletic shoes and other gear, will be a key industry stakeholder in this EFRI project.

“adidas brings external validation of what we’re doing in terms of translational impact,” Long says. “It improves the chances of us taking what we learn here at ASU and moving it into the marketplace.”

The company also provides facilities and testing that will help evaluate the properties of recycled foams to make sure they meet the needs of adidas and other companies.

Working toward a more sustainable future

The entire EFRI team is excited to work together and learn from each other on a project with immense potential impact.

“Polyurethanes are an enormous fraction of the polymers we manufacture and use, and right now we have no viable recycling strategies,” Green says. “If we are able to accomplish what we put into the proposal it will have an immense societal impact.”

Russell says she is excited for the opportunity to recognize that technology solutions must be made alongside sustainable behavioral and economic advances and analyses of unintended consequences — and to demonstrate a model for tackling other problematic but important sustainability challenges.

“If we cannot get people to make use of the innovation we are developing, then even the most perfect technology and innovation breakthroughs will ultimately be useless,” Russell says. “We are aspiring not only to find engineered solutions to the challenges of depolymerization of PUFs, but also to construct a systems view that ensures these solutions will be economically viable, scalable and environmentally preferable. To accomplish this, we needed to build in consideration and engagement with the human dimensions of recycling and a circular economy from the start.”