Fracturing bones and traditional views of civil engineering

Ira A. Fulton Schools of Engineering researchers and graduate students assist Mayo Clinic in studying fracture patterns in human femurs

When most people think of civil engineering, images of construction sites, bridges and tunnels will likely come to mind. However, a recent collaboration between Arizona State University and Mayo Clinic is placing civil engineers in a new light.

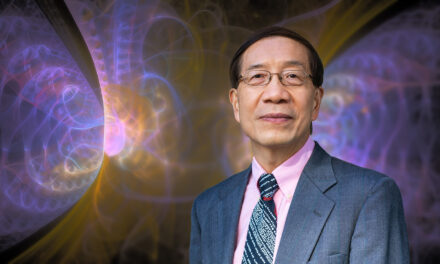

Subramaniam “Subby” Rajan, a civil engineering professor at ASU has conducted a number of material testing studies on items such as jet engines and bulletproof vests. Now he is turning that attention to human bones. Photographer: Monica Williams/ASU

“There is a huge world out there where engineers can use their skills in areas that are traditionally not associated with civil engineering,” says Subramaniam “Subby” Rajan, a civil engineering professor in the Ira A. Fulton Schools of Engineering at ASU.

Putting that concept to the test, Rajan has spearheaded a number of projects in the School of Sustainable Engineering and the Built Environment, part of the Fulton Schools, with private companies such as Honeywell and Raytheon, and government organizations such as the Federal Aviation Administration and NASA. He has aided in the materials testing of everything from jet engines to bulletproof vests — efforts that have not only expanded his knowledge of civil engineering, but also that of his students and research assistants who get to participate in the studies as well.

“If you ask a person on the street or even a practicing civil engineer whether can civil engineering skills be used in answering questions dealing with bone fractures the answer will inevitably be no; there is not a connection between the two. However, there are a lot of connections,” Rajan says.

In his latest research project, Rajan is using his civil engineering expertise to help forensic researchers draw more accurate conclusions about the impact of trauma made on the human body.

Interdisciplinary research

With a long track record of applying civil engineering mechanics to diverse research projects, Rajan was contacted by researchers at Mayo Clinic in Arizona. The team is actively working on a project that could redefine the process for identifying trauma made to human remains. More specifically, the research could allow forensic anthropologists to determine the time at which blunt force trauma may have occurred to a human body with greater precision and, ultimately, if the trauma played a role in a person’s death.

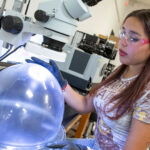

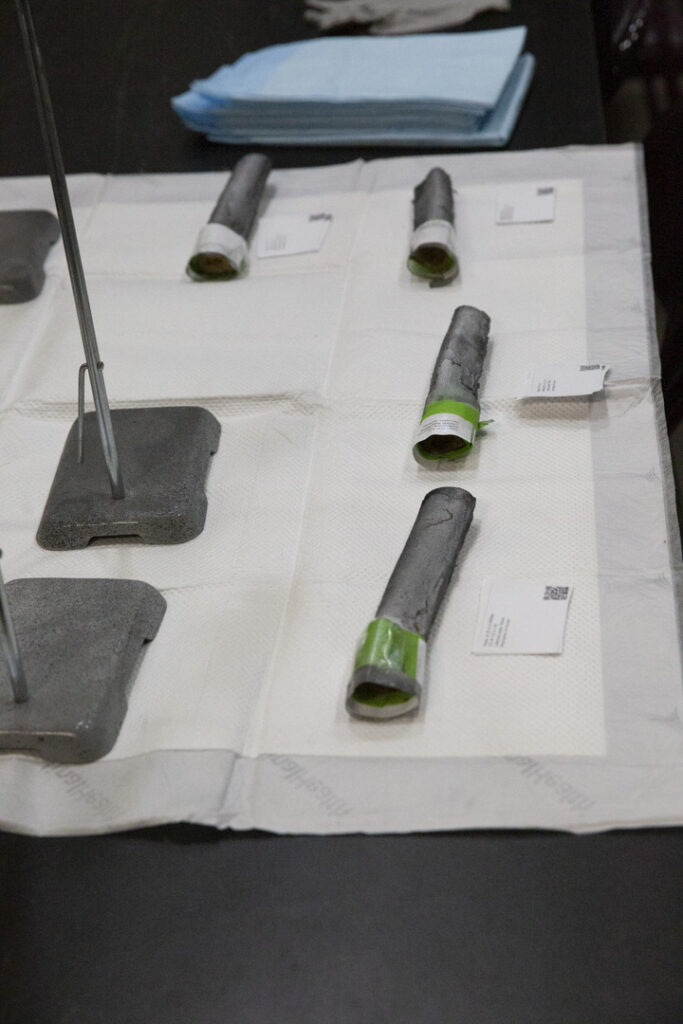

Donated femur bones are coated in a black and white speckled spray paint that allows high-speed cameras to capture the deformations on the surface of the sample during fracture testing. Photographer: Monica Williams/ASU

“This work is important to forensic scientists because knowing whether a fracture occurred perimortem — at or around the time of death — versus postmortem can give us important information about the cause and manner of death with crime scene investigations,” says Natalie Langley, a consultant in the Department of Laboratory Medicine and Pathology at Mayo Clinic in Arizona and president of the American Board of Forensic Anthropology.

The collaborative team at Mayo Clinic also includes researchers from the Center for Regenerative Medicine in Arizona, Biomaterials and Histomorphometry Core Laboratory at Mayo Clinic Rochester, Mayo Clinic postdoctoral research fellow Jessica Skinner, and ASU’s Barrett, The Honors College graduate intern Yuktha Shanavas.

Langley explains in one part of the study femur bones were sourced from males between the ages of 50 and 80 who donated their bodies to scientific research. Those demographic variables were chosen to control for sex and age-related compositional differences in bone. The bones are then heated at controlled temperature and humidity for varying amounts of time to simulate the loss of elasticity bones experienced during the postmortem interval.

“Bone is an elastic material, and it maintains elasticity for some time after death,” Langley says. “By heating the bone, we are able to replicate longer periods of time after death that commonly lead to a bone losing some elasticity, leaving different fracture patterns than if it were broken while still elastic.”

A layer of spray paint is also applied to the surface of the bones so high-speed cameras can detect deformation and surface strain that occur during the impact testing.

Controlling the variables

Langley says her team needed help minimizing the unknowns in their research.

“I contacted ASU initially because we needed an impact tester to induce fractures in a controlled manner,” she says.

Rajan’s team and Mayo researchers created a special apparatus to hold a fragment of femur bone to allow for an impactor to drop at a controlled and monitored rate.

“These are impacts that are strong enough to break a bone, but they are not as high velocity as a gunshot wound,” Langley says. “We even take it one step further and use high-speed photography to measure, or track the movement of the bone during the fracture process.”

This allows her team to consider what forces are being distributed across the bone.

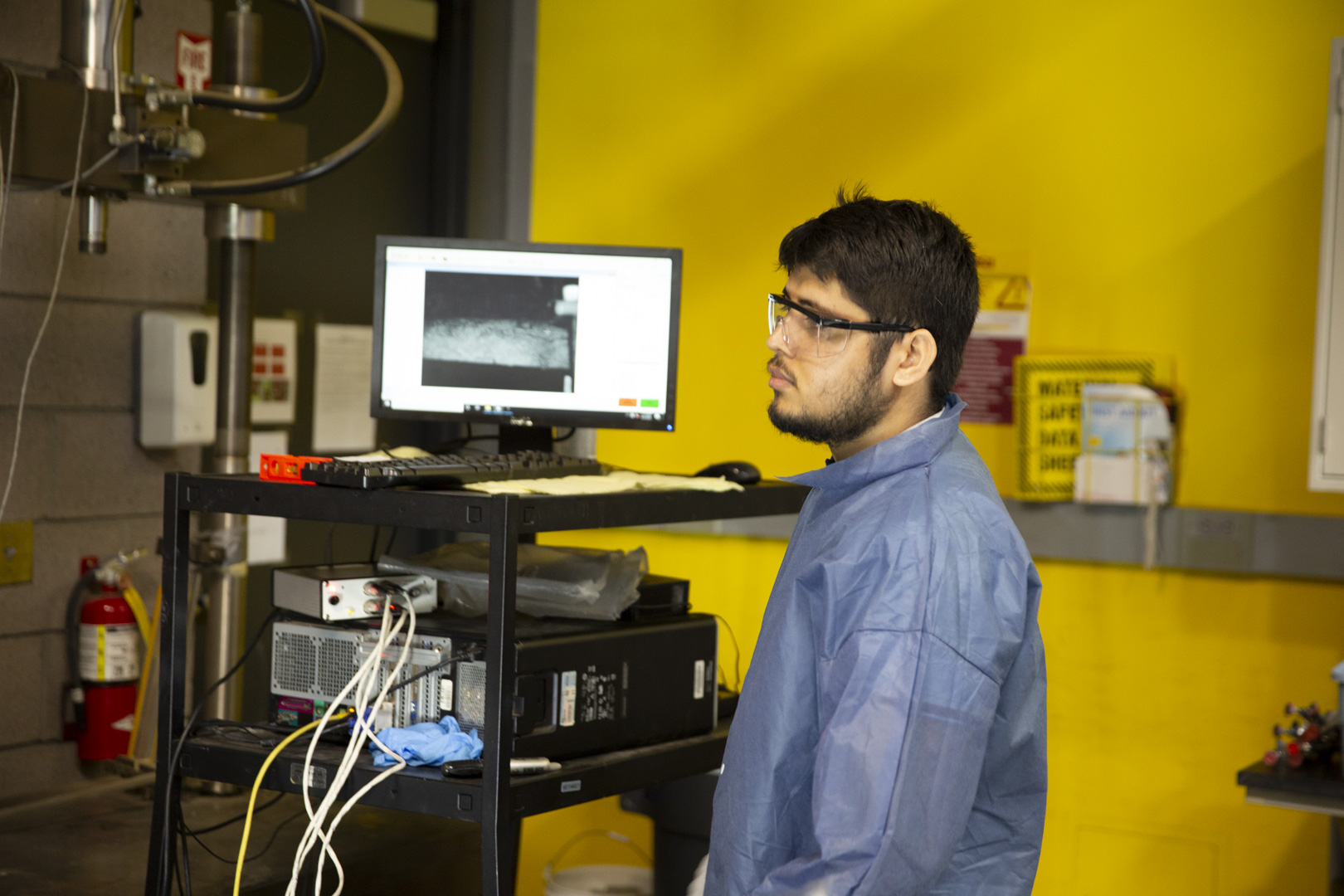

Ashutosh Maurya, a doctoral student of civil, sustainable and environmental engineering, volunteered to participate in the collaboration with Mayo Clinic in hopes of expanding his experience working with individuals in different research fields. Photographer: Monica Williams/ASU

Once the bone is fractured, it is handed back over to Langley and her team for a thorough review and documentation of the fracture characteristics.

“One of the things we look at is the pattern of the fracture,” Langley says. “Fractures that occur at, or around the time of, death have a certain appearance; and those that occur much longer after death, when the bone is not as elastic, have a different appearance.”

“We captured 5,000 frames per second and were able to tell where the weight struck the bone and where the cracks were propagating in the bone,” says Ashutosh Maurya, a graduate research assistant who volunteered to participate in the bone testing.

Maurya is completing his doctorate in civil, sustainable and environmental engineering in the Fulton Schools. Despite the bone testing research having a different focus from his dissertation work, he felt it was a great opportunity to expand his skills as he explores impact dynamics problems connected to aircraft structures.

“If you look at almost any research, you will see people from different areas working together,” Maurya says. “This will definitely help me in my future career as I collaborate with non-engineering background professionals and manage projects across disciplines.”

It is a philosophy Maurya’s mentor Rajan has tried to instill in all of the students that pass through his classroom.

“It’s only when you start looking at the fundamental tools that are used across all these different problems, that you find there are a lot of commonalities,” Rajan says. “For this specific project we are able to make an impact beyond what is commonly expected of civil engineers.”

In the coming months, Langley and her team will be compiling data from the fracture testing, tracking formations and markings left in the bones at different intervals of drying. The results will then be used to create a new standard for determining when trauma was inflicted on a crime victim.

“Working with Rajan and his team allowed us to think outside of the box of our own work,” Langley says. “Their knowledge in controlling the variables with forcefully creating fractures gives validity to our work, ultimately changing the process for solving crimes and giving closure to families.”

Learning by Breaking from ASU News on Vimeo.