Exploring metamaterials for aircraft surface advances

ASU researcher leads interdisciplinary, multi-institution research team to investigate new passive solutions for aircraft performance and defense applications

Airplane wings are typically made of smooth metal surfaces — a design that has worked well for decades on aircraft ranging from commercial airliners to fighter jets. However, materials science and manufacturing advances have created new opportunities to engineer more sophisticated aircraft surfaces that interact with and control airflow in new ways.

Experimental methods of flow control typically use active solutions, such as adding jets or other moving parts. However, active solutions add weight, complexity, cost and require more energy use.

Yulia Peet, an associate professor of aerospace and mechanical engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, is leading a team of researchers to explore passive methods of flow control.

The team aims to gain a new understanding of how turbulent air flows interact with surfaces. The researchers will then design specially engineered metamaterials that influence flows in ways that can achieve high performance gains without the drawbacks of active solutions.

“We will generate a lot of new knowledge about these materials’ interactions with fluids such as airflow,” Peet says. “We’re trying to take it a step further by not only characterizing the fundamental physics but also seeing if we can go all the way through to fabricating those materials and testing them.”

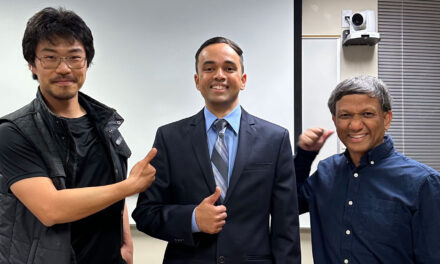

Peet is collaborating with Lorenzo Valdevit, a professor of materials science and engineering and mechanical and aerospace engineering at the University of California, Irvine, and Kenny Breuer, a professor of engineering at Brown University, to study this new use of metamaterials for aerospace applications.

The research team is supported by a three-year, $2.25 million grant from the Air Force Office of Scientific Research National Science Portal Initiative to accelerate multidisciplinary scientific research of critical need to the U.S. Department of Defense, including new solutions for interactions between air and surface materials. The opportunity also focuses on increasing the diversity of people involved in research and the aerospace and defense workforce.

“Every exciting research project that I can think of is interdisciplinary,” Valdevit says. “Working in multi-university teams enriches everyone’s experience, both intellectually and culturally. I very much look forward to working with this great team on this exciting project.”

Disrupting flows for better performance

Peet brings expertise in characterizing and modeling the physics of flows and how they interact with materials. For this project, she was inspired to look more closely at flow separation and how this often-detrimental aspect of aerodynamics can be mitigated for improved performance.

When a plane is flying, it essentially makes the air “stick” to it as the airflow follows along a wing surface. Certain changes in turbulent airflow or the angle of flight can cause the flow to separate from the wing surface. When this happens, an aircraft can lose lift or experience increased drag or other undesirable effects.

One way to influence flow and suppress separation is by harnessing the frequencies present in the airflow. Like sound waves, air motions contain waves of different frequencies that result in different pressure signals on surfaces.

“We can optimize these interactions to make air vehicles move faster or consume less energy or make them quieter,” Peet says.

However, there isn’t a lot of information available about exactly which frequencies to target and how the team can alter them to interact with flow separation in useful ways.

“It’s a very difficult phenomenon to study and characterize all of these interactions between materials and fluids, especially when the fluids are turbulent like during an aircraft flight,” Peet says. “Computers have not been powerful enough and numerical methods haven’t been developed to the point that we need them to be. Now we’re starting to enter an era when this research becomes possible.”

Once Peet and the research team better understand which frequencies lead to separation, they can figure out how to create specially designed resonant metamaterials that can influence these frequencies. This is one of the goals for the team’s research.

New uses for metamaterials

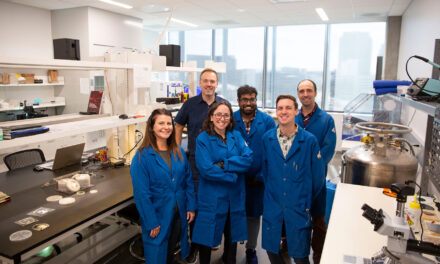

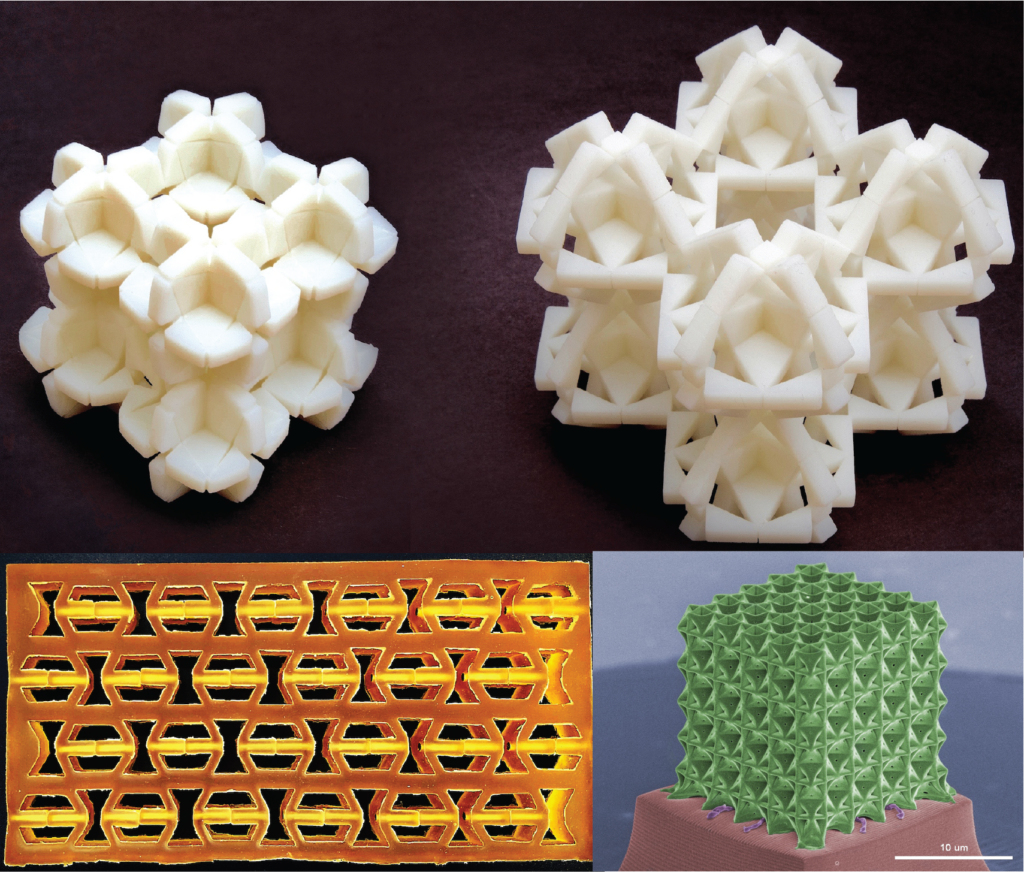

Examples of metamaterial structures developed by Lorenzo Valdevit at the University of California, Irvine. Metamaterials are specially engineered solids with periodic patterns that exhibit properties not found in natural materials. Valdevit is exploring how metamaterials can be designed to interact with airflow frequencies — a new application of the technology. Image courtesy of Lorenzo Valdevit

Peet was excited to connect with Valdevit for this project because he is one of the few researchers studying and manufacturing metamaterials who also understands aerodynamic challenges due to his aerospace and mechanical engineering background.

Metamaterials are engineered solids with repeating patterns, designed to exhibit combinations of properties that don’t exist in natural materials. The intervals and shapes of the precise patterns and the substances a metamaterial is made of can be designed to interact with waves by absorbing, blocking or amplifying certain frequencies.

While metamaterials have been studied and developed for decades, most investigations into interactions between metamaterials and waves have focused on light or electronic applications. The field of acoustic and elastic metamaterials, which can be used to interact with the frequencies found in airflow, is much newer.

Valdevit will explore how to design mechanical metamaterials that influence flow across combinations of frequency ranges never targeted before. The challenges Valdevit sees for this task involve designing metamaterials small enough for use on an aircraft that can also interact with the frequencies the team identifies as good targets for controlling separation.

Using innovative experimental techniques

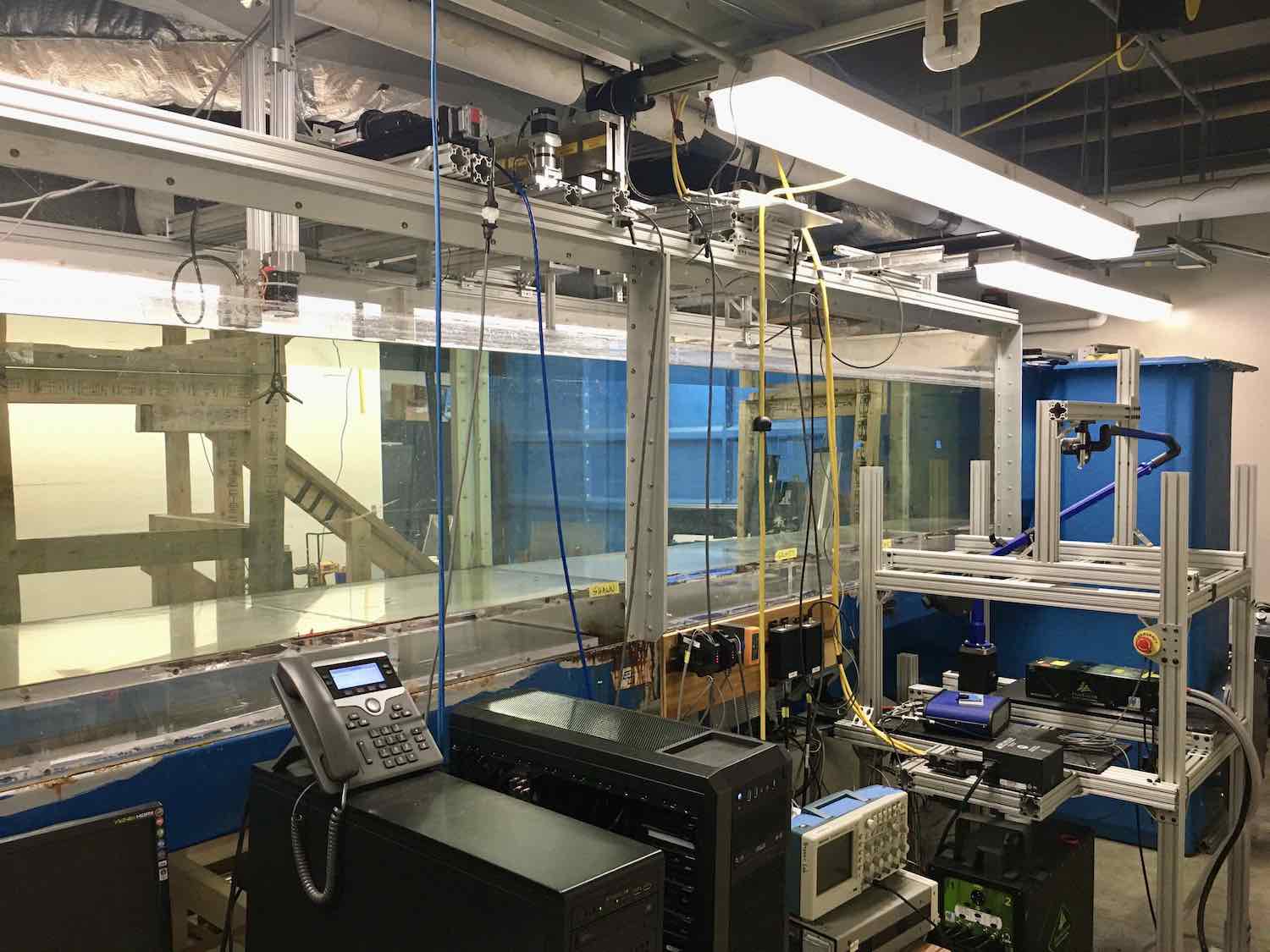

The cyber-physical system at Brown University that will be used by the team for experiments exploring fluid interactions with metamaterials. The system measures characteristics of real water flowing in it while actuators simulate how a metamaterial would interact with the flow. Photo courtesy of Kenny Breuer

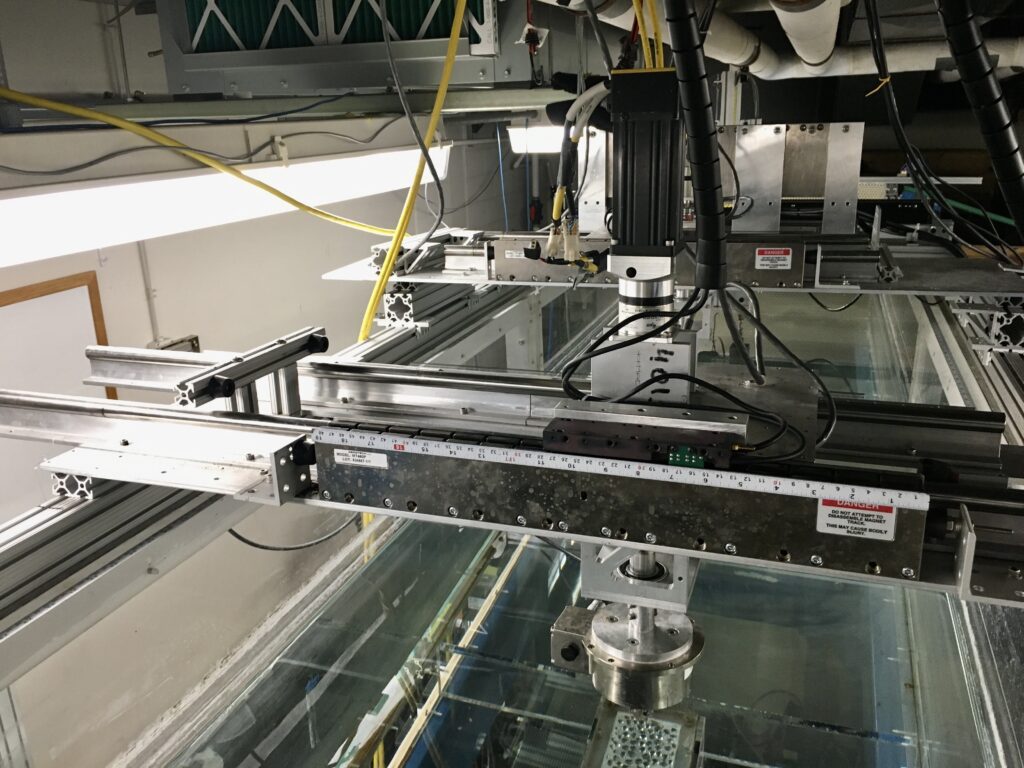

The cyber-physical system at Brown University that will be used by the team for experiments exploring fluid interactions with metamaterials. The system allows the team to test all kinds of metamaterial designs before manufacturing actual metamaterial samples. Photo courtesy of Kenny Breuer

Breuer, an experimental fluid dynamics researcher, is among the first to create and use cyber-physical systems — which integrate real and simulated components — to study interactions between flows and surfaces.

The research team will design experiments using the cyber-physical system to test a range of frequencies and pressure disturbances using water and how they interact with a variety of simulated resonant metamaterial configurations. Using water rather than airflow in early-stage research will give the team more detailed data about the flow to work with.

By first simulating the metamaterial properties with sensors and actuators, the team can evaluate more options faster with lower costs and risks than if they manufactured actual metamaterials at this stage.

When the team finds a promising metamaterial structure, Valdevit will use advanced additive manufacturing and 3D printing capabilities in the Institute for Design and Manufacturing Innovation at UC Irvine to build physical samples that can be tested in a wind tunnel to verify the simulations on computers and in the cyber-physical testing system.

This will be the first time the interactions between flows, surfaces and metamaterials will be shown in full-scale experiments in wind tunnels.

“Our results will help materials designers optimize the development of new materials that, coupled with complex fluid mechanics, will allow for new capabilities to be achieved,” Breuer says.

If successful, a passive, tunable solution for flow separation control could transform many aerospace and defense applications, including aircraft and missile defense systems.

Diversifying the minds solving engineering challenges

In addition to generating new knowledge and solutions, the research team is pursuing strategies to bring a broader mix of people into research, government and industry careers.

“The diversity of minds is strengthened by this call from the National Science Portal Initiative,” Peet says. “We want to make sure we are not losing out by not engaging underrepresented populations because they can provide new ways of looking at things. Educating more people means we have better-qualified personnel to do the work.”

The National Science Portal Initiative funds historically Black colleges and universities, Tribal Colleges and Minority Serving Institutions to build their research capacities. ASU is a Hispanic-Serving Institution, and UC Irvine is designated an Asian American and Native American Pacific Islander-Serving Institution as well as a Hispanic-Serving Institution. Brown University has many programs in place to recruit researchers from diverse backgrounds, including the Leadership Alliance.

“It means a lot that we are now able to receive support to advance this minority population and build up capacity here that otherwise might not have been possible,” Peet says.

The team plans to engage, train and educate underrepresented students, professionals, Air Force Research Laboratory scientists and the wider aerospace and defense industry.

“DOD agencies are constantly looking for talent and are working hard to diversify their workforce,” Valdevit says. “Universities first and foremost produce talent, and ASU and UC Irvine are particularly good at producing a diverse range of talent. Our effort will help with matchmaking.”

Breuer, Peet and Valdevit will use their strengths in engaging diverse learners to offer research opportunities for underrepresented students. They’ll also leverage partnerships with Edwards Air Force Base and General Electric as well as forge new partnerships with Air Force scientists and industry to share their research findings.

Peet says problems like flow separation control require multidisciplinary thinking that is still lacking among students and professionals who focus on one discipline at a time. She says understanding the need to collaborate with other researchers and consider the full breadth of material and fluid problems is something the team hopes to foster in students and professionals as part of this project.