ASU engineering begins major industry collaboration

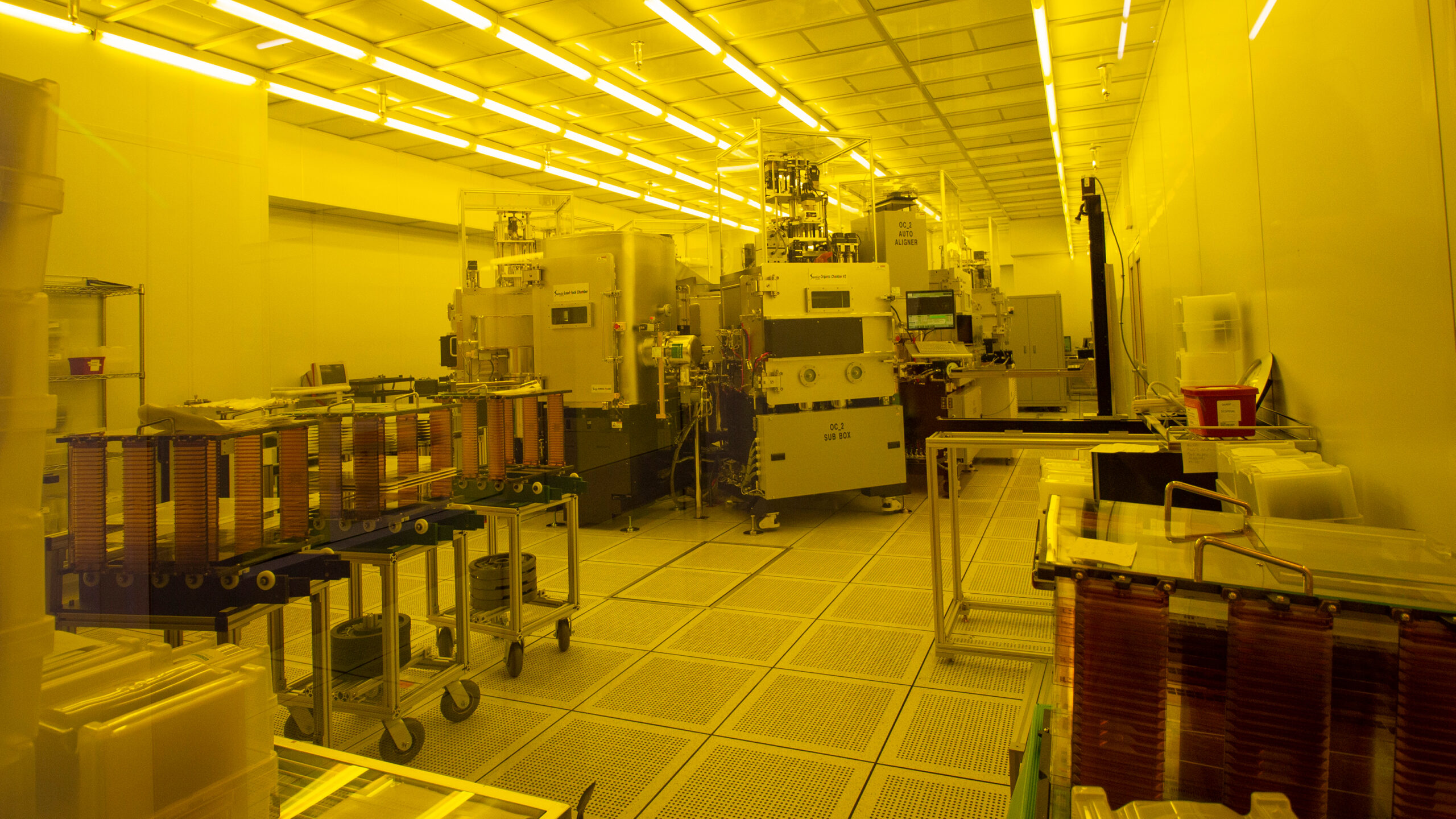

Above: ASU's MacroTechnology Works is a state-of-the-art research center with office space, labs and equipment to support collaboration with commercial partners such as Applied Materials. Photographer: Erika Gronek/ASU

Arizona State University has entered a new collaboration to further advance the Phoenix metropolitan area as an important hub of the global semiconductor industry.

Applied Materials, a California-based materials engineering company, is leasing substantial lab space at ASU’s MacroTechnology Works to support research and development work. Additionally, the company has agreed to fund at least five years of research with faculty members and students in the Ira A. Fulton Schools of Engineering.

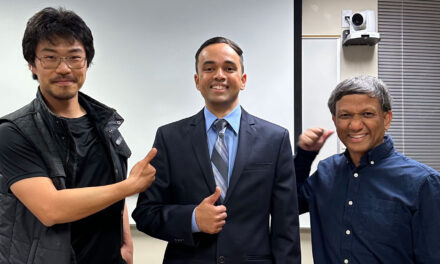

“A key part of our innovation network is engagement with leading universities like ASU, where we are conducting research in materials science and semiconductor technology,” says Mohith Verghese, managing director of engineering management at Applied Materials.

The new collaboration represents a significant validation of ASU’s science and engineering capabilities, since Applied Materials’ manufacturing equipment and solutions are used to produce virtually every new computer chip and advanced display in the world.

According to Zachary Holman, associate professor of electrical engineering in the Fulton Schools and one of the faculty members conducting research for the company, ASU’s facilities play a significant role in this new collaboration.

“There are very few universities with a state-of-the art research center offering ready-to-go office space, labs and equipment for commercial partners,” Holman says. “But our technical expertise also plays a big role. We have dozens of faculty members performing synergistic work on many of the research interests of Applied Materials. We bring a critical mass of skill.”

Holman says another motivation for the company’s decision is excellent student talent. He notes that ASU produces as many or more graduates for the semiconductor industry than any other institution.

Verghese agrees with Holman about the value of the university’s engineering students.

“The high level of talent emerging from ASU every year can help build a pipeline for new college graduates to strengthen our workforce,” he says.

Discussions to establish the collaboration began in 2018 and came to fruition this summer. Applied Materials has agreed to initial contracts with four faculty research groups in the Fulton Schools. Each one outlines objectives, deliverables, a timeline and a budget for graduate student work as well as for materials and supplies. After one year, the company will determine how each research effort is aligning with business needs.

In addition to Holman, selected faculty members include Michael Kozicki, professor of electrical engineering; Sefaattin Tongay, associate professor of materials science; and Heather Emady, assistant professor of chemical engineering.

Kozicki says this opportunity reflects a progressive mindset at Applied Materials. He says the company recognizes that the industry it serves needs constant innovation.

“Customers need fully formed solutions,” Kozicki says, “and the Fulton Schools can add value to the superb products and services that Applied Materials provide.”

Toward that end, Kozicki and his laboratory team will be researching materials for advanced memory devices, an area of focus in which he has 25 years’ experience.

“Developing device technologies is something we can do very well at the university,” he says. “At the same time, Applied Materials can support our efforts to train young engineers in ways that mean something to the marketplace. So, this is a truly symbiotic relationship.”

Tongay adds that the educational benefit extends from students to the Fulton Schools’ engineering programs as a whole.

“Understanding what industry is seeking is a tremendous benefit to all of us here,” he says. “It enables us to identify and explore problems that really need to be solved. Pure scientists and academic engineers can view issues somewhat narrowly. But interacting with major companies like Applied Materials gives us broader perspectives, and that’s very exciting.”

Tongay and his research group will be supporting the development of a new semiconductor base material for advanced transistors.

“In order to develop this material, we need to understand its crystalline structure, its properties, the quality of the material and how this quality influences its performance,” he says. “Our role will be to see how a growth parameter correlates to the material properties and how those properties correlate to the overall platform.”

Emady and her team are also working to explore the inner workings of complex products and processes to a level of depth that companies generally do not pursue in-house.

“Two areas of focus for my team’s research are material flow and heat transfer, and this collaboration involves both of them,” she says. “Right now, we are working alongside Applied Materials to test different models and make sure that new materials flow as they are required. Later during the project, we’ll add complexities including heat transfer to the process.”

Emady shares she is excited to support a project that aligns with what she and her students are already investigating. And like Kozicki and Tongay, she believes direct interaction with industry is invaluable.

“Having an Applied Materials presence locally is an excellent opportunity on many levels,” she says. “Our students, for example, will develop applicable skills through their experiences with the company, and they will become leading candidates for new jobs working with these materials and processes.”

The collaboration is only just beginning, but Fulton Schools faculty and students as well as Applied Materials staff are optimistic about its potential for the future.

Verghese says, “We look forward to working closely with ASU to fast-track the development of new, cutting-edge technologies from ‘lab to fab’” or from laboratory to fabrication.