ASU driving advances in metal additive manufacturing

3D printing technology is taking the world by storm. The ability to print virtually any item with diverse materials is driving the creation of houses, prosthetic limbs, dental implants and more.

A growing area of interest within the field is metal additive manufacturing, the industrial version of 3D printing applied to metals. The technique involves building up successive thin layers of metal on each other to produce high-value critical parts.

America Makes, the national accelerator for additive manufacturing, recently chose Arizona State University to lead a $1 million directed project opportunity to advance additive manufacturing post-processing techniques. The Air Force Research Laboratory will fund the project with supplemental matching funds from the university and its three research collaborators.

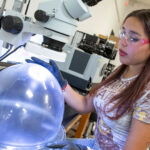

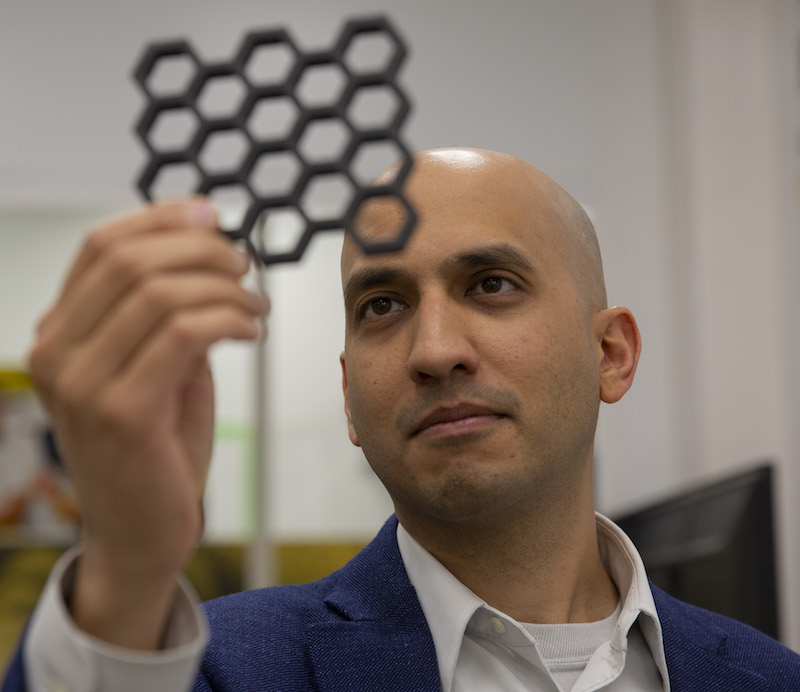

Dhruv Bhate, an associate professor of manufacturing engineering in The Polytechnic School and principal investigator on the America Makes grant, examines a continuous carbon fiber composite honeycomb. Photographer: Erika Gronek/ASU

The project evolved out of the thriving collaboration between the Ira A. Fulton Schools of Engineering and Phoenix Analysis and Design Technologies, Inc., a globally recognized provider of numerical simulation, product development and 3D printing. A group of ASU engineering faculty members and leaders of the Tempe-based company joined forces to apply for the America Makes grant.

Dhruv Bhate, an associate professor of manufacturing engineering in the Fulton Schools who led the proposal effort, will serve as principal investigator for the project. Phoenix Heat Treating, Inc. and Quintus Technologies round out the research team.

“This directed project opportunity places us in a leadership position in metal additive manufacturing,” says Ann McKenna, director of The Polytechnic School, one of the Fulton Schools. “Our school has the largest additive manufacturing academic research facility in the Southwest, which makes us uniquely qualified for the project.”

Cutting-edge capabilities in metal additive manufacturing

Bhate attributes winning the award to the university’s investment to launch the 15,000-square-foot Manufacturing Research and Innovation Hub located on the Polytechnic campus. The space boasts $2 million in cutting-edge polymer, composite and metal 3D printing equipment along with advanced processing, design and analysis capabilities to enable students, faculty and industry partners to help accelerate the growth of additive manufacturing.

This project is the first time ASU is leading an America Makes project since the additive manufacturing accelerator was established in 2012. America Makes is the flagship institute for Manufacturing USA, a network of U.S. research institutions focusing on the development of manufacturing technologies through public-private partnerships.

“Achieving this award through America Makes not only recognizes ASU’s expertise in advanced manufacturing,” says Malcolm Green, associate director of corporate engagement in the Fulton Schools, “but tangibly demonstrates the value and benefit of the university’s industry partnership model.”

Metal additive manufacturing has caught the eye of the Air Force Research Laboratory as a capability that enables rapid innovation. Its specific interest has centered around the use of selective laser melting, a technique designed to use a high power-density laser to melt and then fuse metallic powders. However, a better understanding of structural properties and the impact of post-processing techniques are needed to ensure the laser melting technique can be reliably used to produce qualified parts and certified processes.

The current lack of consensus about best practices for material handling and post-processing leads to higher costs to adopt and employ these technologies.

The main issue the research team will tackle is gaining a deeper understanding of how mechanical properties — such as stiffness, strength and fatigue life — of additive manufactured metal structures change as a function of size. Smaller parts are especially important to the Air Force Research Laboratory because of its interest in fabricating high-temperature nickel superalloys with thin walls and narrow flow channels suitable for aerospace applications.

“Additive manufacturing gives us the capability to design more complex parts with complicated geometries mimicking biological structures like honeycombs and bone,” says Bhate, the principal investigator for the project. “The industry is gradually pushing boundaries to make parts at a range of scales and reduce weight while improving performance.”

A deeper understanding of how 3d-printed structures behave

In particular, the project team will be looking at mechanical properties of as-built metal structures — meaning the parts pulled straight out of the printer without any machining or polishing.

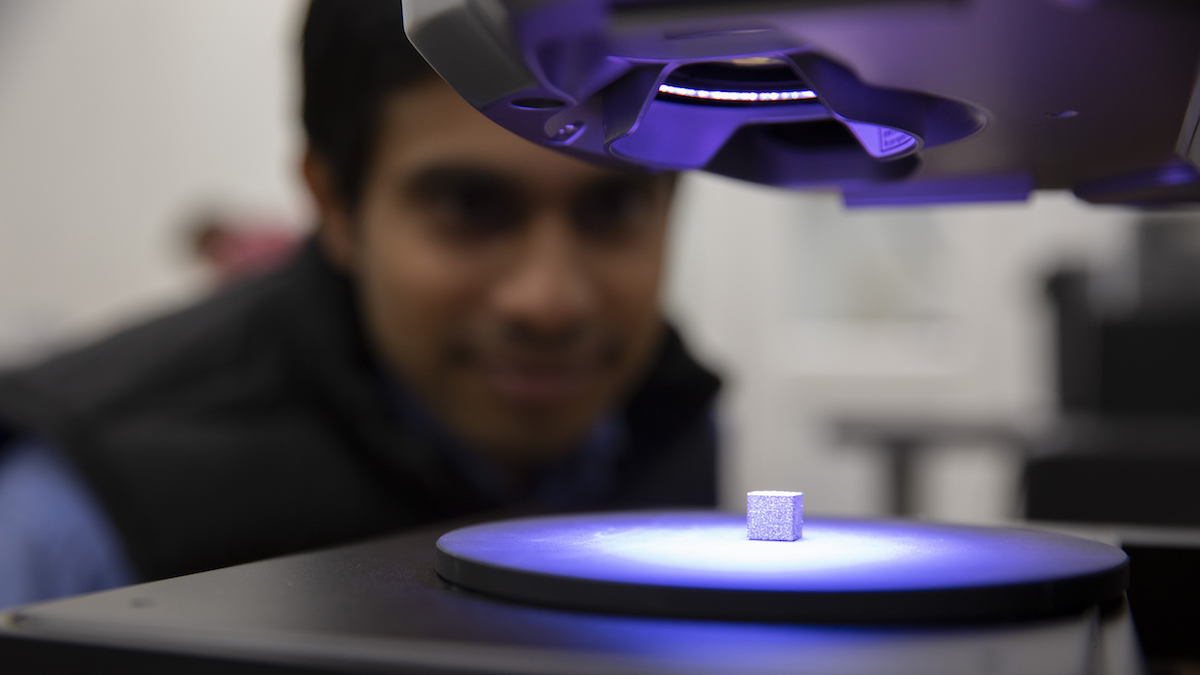

Cameron Noe, a graduate student in systems engineering and engineering associate at The Polytechnic School, prepares the metal 3D printer for a new build. Photographer: Erika Gronek/ASU

When metal parts come out of the printer, the surface is not shiny and smooth like one might expect from traditional metal machining. As-built structures are rough, which introduces many challenges. When loads are applied for some period of time, taken off or reversed and then applied again — a concept known as fatigue — cracks can initiate on the rough surfaces and significantly reduce the component’s lifespan.

“Just like our bones, aircraft components are subjected to all kinds of loads, albeit at much higher magnitudes. For example, every time an aircraft lands on the runway, it applies enormous force to the landing gear,” says Bhate. “If we are to reach the full potential of metal additive manufacturing, we need to understand and be able to predict how 3D-printed structures behave under these loads.”

There are some examples of 3D-printed parts accepted by the Federal Aviation Administration and approved for implementation in aerospace applications, says Bhate, but the vast majority are not as-built structures. They’ve gone through significant post-processing techniques, which can be expensive, especially when dealing with very small, very complex designs.

The project team will also explore the fundamental reasons for how mechanical properties change during post-processing techniques, such as hot isostatic pressing. This thermal processing technique applies high temperature and pressure to rid the metal structure of voids, or little pockets of gas trapped in the part. The team will conduct a controlled study in which some parts will undergo hot isostatic pressing to determine the effectiveness of the technique and how it varies as a function of size.

The Polytechnic School researchers will be responsible for the additive manufacturing of parts and mechanical testing. Two of Bhate’s students have begun the planning and preparation needed to make the project successful, which is set to start in late February.

Paul Paradise and Mandar Shinde, who are pursuing doctoral degrees in materials science and engineering and mechanical engineering, respectively, have started a review of research literature to better understand additive manufacturing characterization techniques.

Paradise worked for several years at a local engineering consulting and contracting firm mostly focused on clients in the aerospace sector, and he has experience with the characterization of shape memory alloys and part design.

Shinde worked in computer-aided crash engineering at a research center of Tata Motors Limited, the largest automobile manufacturer in India.

“After working a few years in the aerospace industry, I have already seen so many amazing ways additive manufacturing is starting to change the design process,” says Paradise. “I want to be along for the ride as it continues to progress.”

Industry partnerships set the stage for greater impact

As for the team’s other collaborators, Phoenix Heat Treating and Quintus Technologies will be responsible for heat treatment and hot isostatic pressing, respectively, to determine the outcome of subjecting thin parts of varying sizes to different thermal conditions.

Phoenix Analysis & Design Technologies will prepare digital 3D scans so researchers can examine surface defects, roughness and the size of parts printed.

“We hope the data and insight generated will help industries design critical parts with a greater degree of confidence,” says Bhate. “Among other things, if we can move toward utilizing more additively manufactured parts in aircraft, we can make planes lighter, they’ll consume less fuel and we’ll make for a better planet.”

The team’s research has the potential to impact a range of industries, including commercial aviation, defense, health care, space exploration and the wider transportation sector. Whether designing critical parts for automobiles, prosthetics or spacecraft, metal additive manufacturing is at the forefront of innovation.

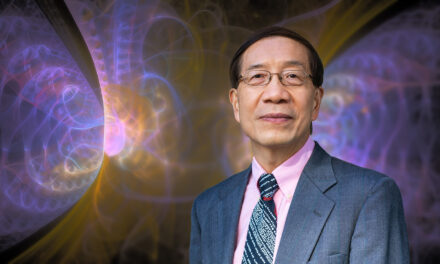

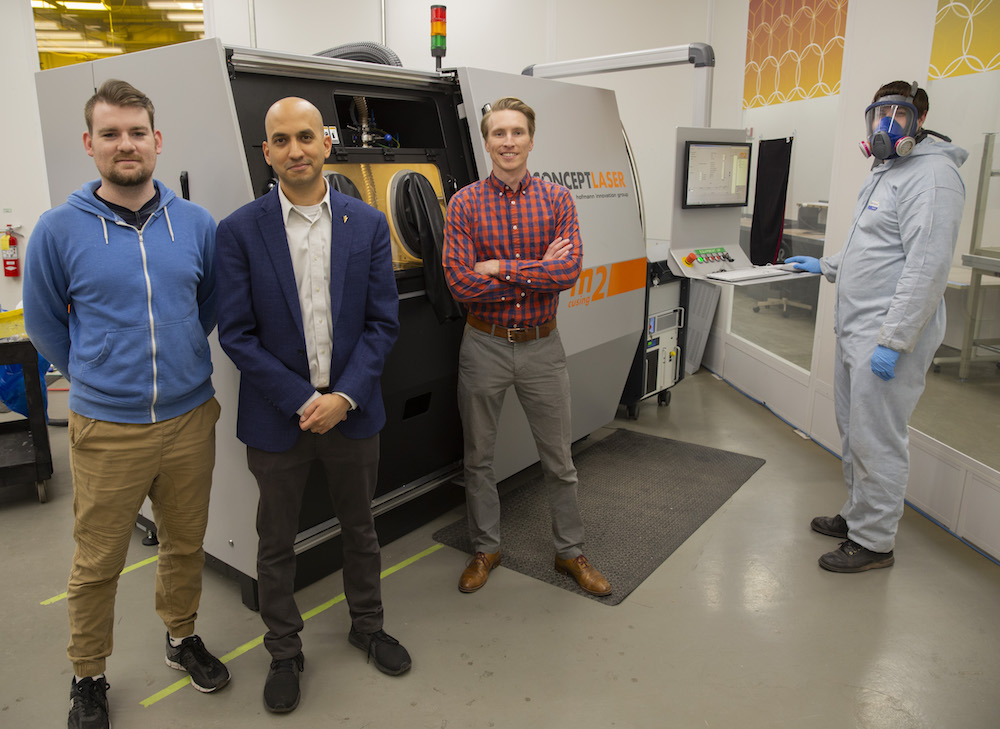

Arizona State University will lead a $1 million directed project opportunity for advancing additive manufacturing post-processing techniques. Project team members (left to right) Philip “Nate” Faint, Dhruv Bhate, Paul Paradise and Cameron Noe stand next to the Concept Laser M2 3D Metal Printer that will be used in their research. Photographer: Erika Gronek/ASU