AI to connect small and medium manufacturing companies with a larger clientele

ASU researcher Farhad Ameri celebrates one year of working on a complex data network project for the National Science Foundation

In the United States, small and medium-sized manufacturers, or SMMs, form the backbone of the manufacturing industry. These SMMs, which make up more than 75% of manufacturing in the U.S., often struggle with sustaining operations due to limited client visibility and incomplete data sets.

To address these challenges, Farhad Ameri, an associate professor in the School of Manufacturing Systems and Networks, part of the Ira A. Fulton Schools of Engineering at Arizona State University, is spearheading a transformative research initiative aimed at empowering SMMs through artificial intelligence, or AI, in conjunction with data-driven solutions.

Ameri’s work to facilitate resilient manufacturing is a part of a larger initiative funded by the National Science Foundation, or NSF, called the Prototype Open Knowledge Network, or Proto-OKN. The NSF has invested $26.7 million into a broader project, which aims to build a publicly accessible, interconnected set of data repositories and knowledge graphs to enable data-driven, AI-based solutions for a wide array of societal and economic challenges.

“We are the only project focused solely on manufacturing,” Ameri says. “We aim to map the capabilities of small and medium-sized manufacturers and publish that data publicly using a standard language in the form of a knowledge graph.”

Within the broader project, Ameri is leading the development of the Supply and Demand Open Knowledge Network, or SUDOKN, a specialized network designed to enhance the visibility and resilience of SMMs.

Farhad Ameri, an associate professor in the School of Manufacturing Systems and Networks, walks the hallways of the Innovation Hub, the largest academic additive manufacturing research facility in the southwestern United States. Photographer: Aisha Kaddi/ASU

Understanding the research

At its core, Ameri’s research is about enhancing data efficiency for decision-making in manufacturing.

“In simple terms, our goal is to enrich data,” Ameri says. “If we have high-quality data, then software agents and AI-powered tools can better understand and interpret the data to make more informed decisions.”

To achieve this, Ameri and his team are developing a set of reusable manufacturing ontologies, or the language used to describe a system, and deploying tools and methods for data collection, validation, harmonization and ingestion. These efforts will then serve as a resource for supply chain managers and other stakeholders.

“Let’s say you want to find an aerospace industry manufacturer based in Arizona who is an expert in micro-machining of aerospace-grade material,” Ameri says. “While that may seem like a simple task, it’s often too difficult to locate.”

One of the challenges SMMs face is the lack of visibility into their operations and capabilities. Often, information about manufacturers is hidden in proprietary commercial databases or scattered across various platforms, making it difficult for supply chain managers to identify potential partners or suppliers.

The SUDOKN project aims to overcome this inconvenience by providing a publicly accessible, standardized data set that makes it easier to find and assess manufacturing capabilities.

The role of AI and data analytics

AI and data analytics are central to the success of SUDOKN. By developing the AI capabilities of this new system, Ameri’s team will be able to process vast amounts of data and provide real-time insights into the strengths and weaknesses of manufacturing companies.

“I want to help and support the small manufacturers by providing them with data and AI support that will ultimately increase their visibility and resiliency” Ameri says.

A diagram of a knowledge graph displaying a manufacturing company’s resources, including its facilities and certificates. Photo courtesy of Farhad Ameri.

The use of knowledge graphs, a key component of the project, allows for a more intuitive and accurate representation of data at a semantic level. They enable a more dynamic and interconnected understanding of manufacturing capabilities, making it easier for AI systems to process and analyze the data.

“If you want to capture and mimic actual human thinking, it’s counterproductive to put that pattern of thinking into simple tables,” Ameri explains. “It should really go into a complex knowledge graph.”

Illustrating the impact

Consider a small manufacturer in Arizona that specializes in producing precision components for the aerospace industry. Despite its expertise, this company struggles to compete with larger firms due to limited visibility and a lack of sophisticated data management tools.

With SUDOKN, however, the manufacturer’s capabilities would be included in a publicly accessible, standardized data set, making it easier for potential clients and partners to discover and collaborate with them.

The system would not only identify the relevant companies but also provide insights into their production capacities, expertise and potential areas of risk. This level of visibility could significantly enhance the resilience and agility of the supply chain, ensuring that even small manufacturers have the opportunity to contribute to critical projects.

For instance, during the COVID-19 pandemic, the lack of reliable data made it challenging to identify manufacturers capable of producing ventilators at a large scale. Had there been a robust data set like SUDOKN, the system could have quickly connected companies with the necessary capabilities to meet urgent health care demands and potentially save lives.

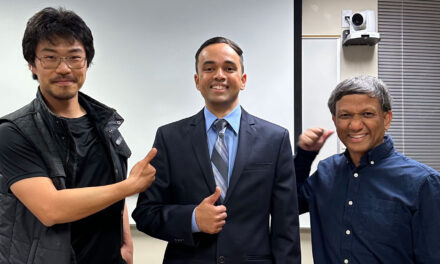

Farhad Ameri, an associate professor in the School of Manufacturing Systems and Networks, conducts research for his Prototype Open Knowledge Network project, Proto-OKN. Photographer: Aisha Kaddi/ASU

The bigger picture: SUDOKN’s role in Proto-OKN

Ameri’s research is just one of 15 projects under the Proto-OKN umbrella, each focused on addressing challenges in various areas, from health sciences to environmental research. However, SUDOKN is unique in its focus on manufacturing, particularly on supporting the often-overlooked SMMs.

The success of SUDOKN will not only benefit manufacturers, but also serve as a model for other sectors to mimic.

As Ameri and his team continue to develop and refine the network, they will collaborate with other Proto-OKN projects and institutions such as Purdue University and the Georgia Institute of Technology, sharing insights and best practices.

“In October, at the conclusion of the project’s first year, we will go to the NSF headquarters in Virginia to demonstrate the current outcomes and deliverables of the project,” Ameri says.

This close collaboration with NSF and other stakeholders underscores the significance of the project and its potential to drive innovation across multiple industries.

Looking ahead: The future of manufacturing

As the SUDOKN project progresses, Ameri hopes to create a comprehensive, user-friendly knowledge graph, supported by intuitive user interfaces, that will enhance how manufacturing capability data is currently accessed and utilized.

“The knowledge graph itself is a major product,” he says. “Right now, we have about 15,000 companies in our data sets. If we can continue to capture additional companies, we will eventually have a complete data set for end users such as the National Institute of Standards and Technology and Manufacturing Extension Partnership centers.”

Farhad Ameri, an associate professor in the School of Manufacturing Systems and Networks, poses in the hallways of the Innovation Hub, the largest additive manufacturing facility in the southwestern United States. Photographer: Aisha Kaddi/ASU

The ultimate goal is to create a system that is intuitive enough for manufacturers with no prior understanding of ontologies, a structured framework for organizing information and categorizing data, and knowledge graphs to navigate and use effectively.

By the end of the three-year project, Ameri and his team aim to have a fully functional AI-powered system that not only enhances the visibility and resilience of SMMs but also serves as a first-line resource for supply chain managers, policymakers and other stakeholders.

“The National Science Foundation remains closely engaged with my team and this project,” Ameri says. “We are all excited to see the outcome and its impact on the manufacturing space.”