ASU engineering lab space drives student and industry collaborations

Industrial Automation and Robotic Systems Laboratory fuels the future of manufacturing through hands-on learning opportunities

As a propeller of economic growth, job creation and innovation, manufacturing engineering is part of the backbone of the U.S. workforce.

Expanding manufacturing training has the potential to boost production efficiency, lower employee turnover and create a more competitive workforce by introducing and developing specialized skills. In the long run, the efforts made today will equip future engineers to enter the job market.

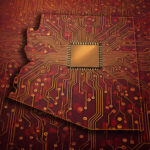

The Polytechnic campus at Arizona State University has been rapidly evolving into a nexus for higher education, investing in learning centers that add value to student life and the community at large.

The Industrial Automation and Robotic Systems Laboratory, or IARS Lab in the Ira A. Fulton Schools of Engineering, is a fundamental resource for ASU students. The lab focuses on fostering collaboration between academia and industry, providing a space where students can gain hands-on experience working with industry-grade equipment and learning more about manufacturing processes.

With the recent growth in median salaries for jobs such as engineering managers, manufacturing plant managers and quality control managers, students have a unique opportunity to set themselves apart as they enter the workforce.

“Industrial robotics and smart automation are cornerstones for the future of manufacturing,” says Professor Binil Starly, director of the School of Manufacturing Systems and Networks. “Beyond classwork, students will participate in project-based learning that can support industry for the next decade.”

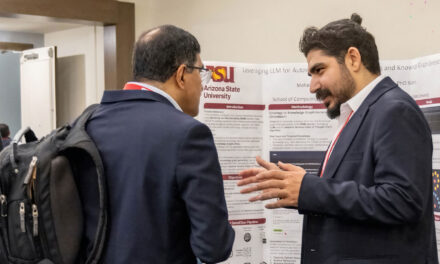

A Fulton Schools senior capstone team discusses the details of their industry-sponsored project in the Industrial Automation and Robotic Systems Laboratory. Photographer: Aisha Kaddi/ASU

Equipped with advanced automation technology, the lab provides an immersive training ground that compliments the School of Manufacturing Systems and Networks workforce development efforts and provides a dynamic learning environment.

The Society of Manufacturing Engineers, or SME, and the Association of Advancing Automation, or A3, are two organizations with student chapters that operate in the lab. Both chapters provide industry-recognized training and certifications to support a focus on integrating industry opportunities with higher education. Students participating in SME and A3 gain insights into the many career opportunities offered by the manufacturing industry.

The work in the IARS Lab is also heavily integrated into the Fulton School’s engineering education curriculum, particularly in courses related to industrial automation. At the undergraduate level, students are provided with a strong foundation in core concepts, preparing them for both professional careers or research at the graduate-student level.

Graduate students can use the foundation they gain in the lab to further their research of advanced manufacturing systems. This layered approach enables students to progress from basic knowledge to advanced applications.

Industry partnerships are another key component of the lab. Companies like FANUC America, Honeywell, Rockwell Automation and APT Manufacturing Solutions have donated equipment and provided support to enhance the student learning experience.

“The overarching objective of this center is to reshape American manufacturing through high-level technical education and collaboration with industry,” says Jerry Gintz, a teaching professor of manufacturing engineering and robotics in the School of Manufacturing Systems and Networks, part of the Fulton Schools.

The lab’s collaboration with Honeywell has been particularly powerful. Industrial equipment utilizes the same technology students will encounter in the field, leading to engineers who are better prepared to tackle the challenges of modern manufacturing.

“This is the most impactful lab in the country, offering students unparalleled insight and foundational knowledge into manufacturing systems,” says Jason Floor, machining technology lead at Honeywell.

One of the lab’s most significant contributions is its focus on practical skills development. Unlike many programs that emphasize theoretical knowledge, the IARS Lab takes a hands-on approach to learning. Students engage directly with industrial automation systems, gaining experience with equipment used in real manufacturing settings. This prepares them to enter the workforce with practical skills that go beyond classroom education.

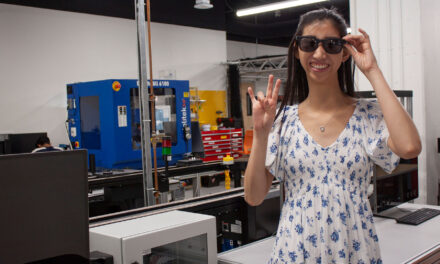

Jason Floor, automation and digital transformation team leader at Honeywell Aerospace, demonstrates specialized technology used in the industry to Fulton Schools students in the Industrial Automation and Robotic Systems Laboratory. Photo courtesy of Honeywell Aerospace

In addition to equipment donations, industry leaders actively participate in the lab’s educational initiatives such as capstone projects and events like Innovation Showcase. Industry members serve as mentors and guest speakers, sharing their valuable expertise with students. This direct interaction bridges the gap between academic learning and professional application, giving students valuable guidance from professionals.

“Getting engaged early in events like Innovation Showcase allows us to anticipate and brainstorm valuable interactions and projects that will accelerate learning and access to our industry,” says Michael Cook, director of global industry-academia engagement at Rockwell Automation.

Through equipment donations and professional guidance from industry experts, Rockwell Automation is bringing real-world automation systems into the university setting, enabling students to learn with tools that reflect current industry practices. This collaboration has been particularly beneficial in preparing students to excel in both design and manufacturing roles. By engaging with industry partners during these projects and showcases, students can explore potential career paths and internships.

Many centers only scratch the surface in their approach to student learning, the Fulton Schools remains dedicated to providing a student experience that emphasizes practical application. While APT Manufacturing Solutions’ interaction with students is limited due to geographical distance, the company’s leaders say they recognize the value in ASU’s approach to education.

“The vision that ASU has for robotics, controls and engineering is spot on to what industry is searching for,” says Tony Nighswander, owner of APT Manufacturing Solutions.

The lab’s integration of robotics and automation technologies ensures that students are not only familiar with these systems but are also proficient in their use. This practical experience is invaluable, as robots and automation controllers are widely used across industries. The lab enables students to work with both hardware and software aspects of these systems, preparing them to successfully manage and maintain industrial automation systems once they enter the workforce.

Industry partners working with the School of Manufacturing Systems and Networks stress the importance of communication, adaptability and collaboration in the modern workforce. The lab encourages students to develop these skills alongside their technical expertise, preparing them to navigate multidisciplinary environments. According to industry leaders, this combination is essential for success in the rapidly evolving manufacturing sector.

“Our organization needs advanced skills in automation, sensing, robotic actuation and navigation. ASU, with its rich history of innovation, is uniquely positioned to supply qualified candidates for these highly desirable skills,” says Rob Anchondo, vice president and chief technology officer at Honeywell.

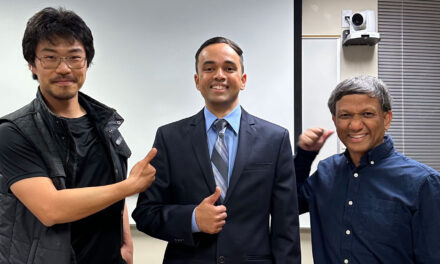

Rahul Pushparajan (at left), a Fulton Schools graduate student, mentors students on the technical application of manufacturing in the Industrial Automation and Robotic Systems Laboratory. Photographer: Aisha Kaddi/ASU

FANUC America has partnered with more than 1,600 schools around the nation. As supporters of academia, the organization offers ASU a significant discount to help expand access to industry-grade automation technology. Instructor training, advanced software, gifts-in-kind and mentorship are additional ways that FANUC contributes to the Fulton Schools community.

“The pathway approach ASU has taken to align students from different backgrounds and educational pursuits is what makes this a great partnership,” says Paul Aiello, executive director of education at FANUC.

“ASU is a regional hub for the workforce development community. This is a school that has established itself as a true center of excellence,” Aiello says.

As the partnership evolves, FANUC hopes to pinpoint where the industry’s technological advancements are heading and help ASU match that progress. With the new Interdisciplinary Science and Technology Building 12 completion on the horizon for next year, FANUC will work with ASU to create a learning hub equipped with the advanced technology needed to master educational development.

Looking ahead, the lab is poised to continue expanding its offerings and partnerships. As the U.S. manufacturing industry continues to grow, the lab will play a crucial role in preparing the next generation of highly skilled engineers.