GOEE alumnus advances career, company

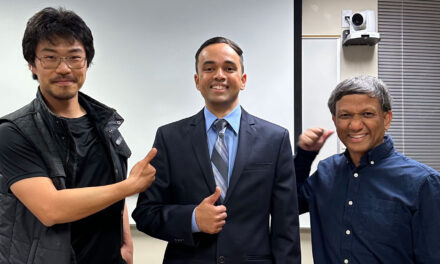

Michael Flatley recently received his master of engineering in quality and reliability engineering, along with Six Sigma Black Belt certification from Arizona State University’s Ira A. Fulton Schools of Engineering.

Flatley is a product application manager for Microsemi, a semiconductor manufacturer specializing in system-engineered integrated circuits and high reliability semiconductors. Microsemi buys wafers, redesigning them to stack 4-5 DRAM into one package, which helps with board space and signal integrity. Flatley works with the sales team, answering technical questions for customers.

The Six Sigma processes are implemented to help realize manufacturing efficiencies and save money.

“Every class I took in this program benefited the company,” says Flatley. “For example, in our reliability class, our group took on a project that Microsemi was going to outsource to a consultant. We saved the company $10-20,000 and have already implemented the processes.”

He says that almost every project had a direct impact on his day-to-day work.

“My capstone project took Lean Six Sigma principles to improve how we develop new processes. In stacking our products, we have implemented an epoxy-based process with silicon spheres which results in a thinner package for our customers. This is a $100,000 savings,” he says.

Flatley is the second Black Belt at Microsemi where Six Sigma is a company-wide initiative.

“We specialize in the military and defense industry where Lean Six Sigma is very important. Having these processes in place makes an enormous difference in our quarterly business reviews, and in how customers view our company,” says Flatley.