Mastering quality and process improvement with Six Sigma

Businesses are always striving to be better, faster and more efficient. The ultimate goal is achieving Six Sigma — or less than 3.4 defects out of a million iterations of a process, or as close to perfect as is reasonably possible. The leaders responsible for making this happen require a mastery of statistics, technology and management.

Master Black Belts are the keystone members of an organization who play critical roles as change agents, thought leaders, trainers, mentors and project leaders of Six Sigma implementation.

Arizona State University’s Ira A. Fulton Schools of Engineering holds a semi-annual Master Black Belt certification program that helps provide experienced Black Belts with the additional technical and business leadership skills they need to be successful in today’s challenging organizational landscape.

The ASU Master Black Belt Program is one of many ways the Fulton Schools connects with industry leaders and provides continuing education for engineers and innovators.

“We remain committed to supporting the learning and development needs of industry professionals by providing programs that provide impact, promote their professional journey and deliver value to their sponsor organizations,” says Octavio Heredia, director of the Fulton Schools Global Outreach and Extended Education office.

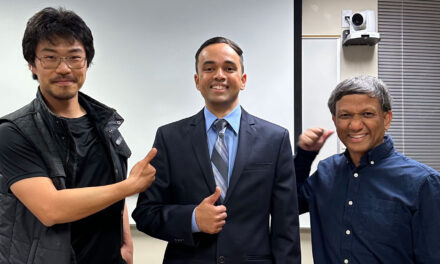

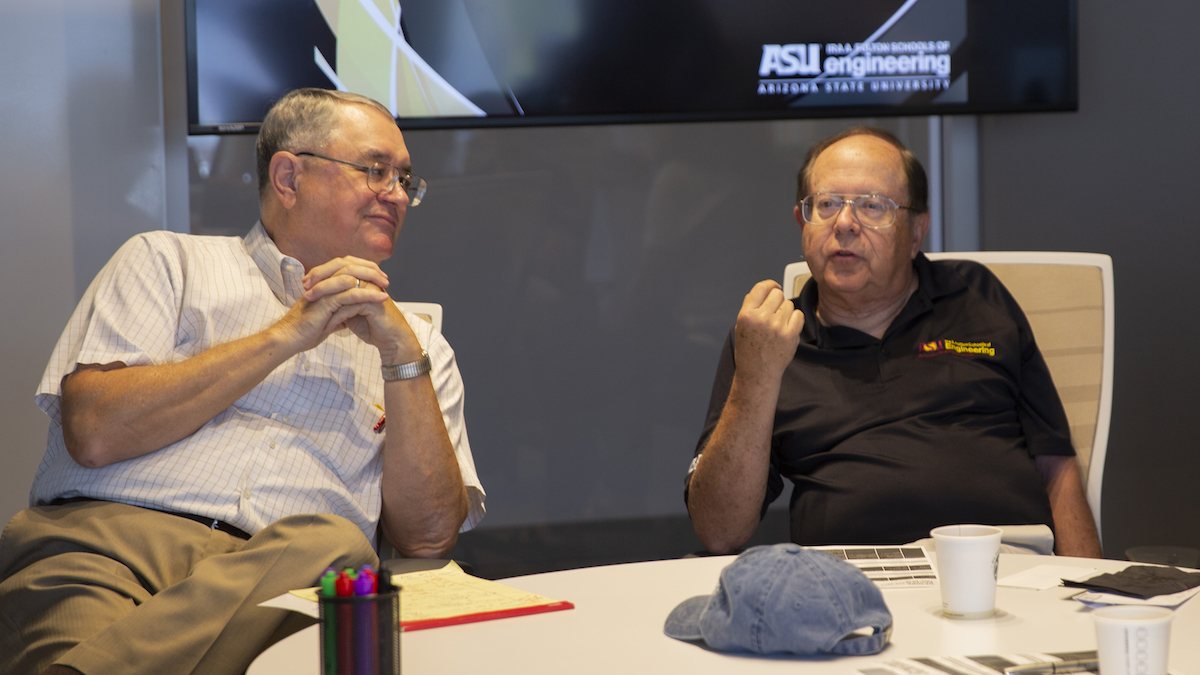

Arizona State University Professor Dan Shunk and ASU Regents’ Professor Douglas Montgomery share their perspectives on opening day of the Ira A. Fulton Schools of Engineering Master Black Belt certification program. Learning from leaders in the fields of industrial engineering and statistics is the highlight of many past participants’ experience in the program. Photo courtesy of the Global Outreach and Extended Education office

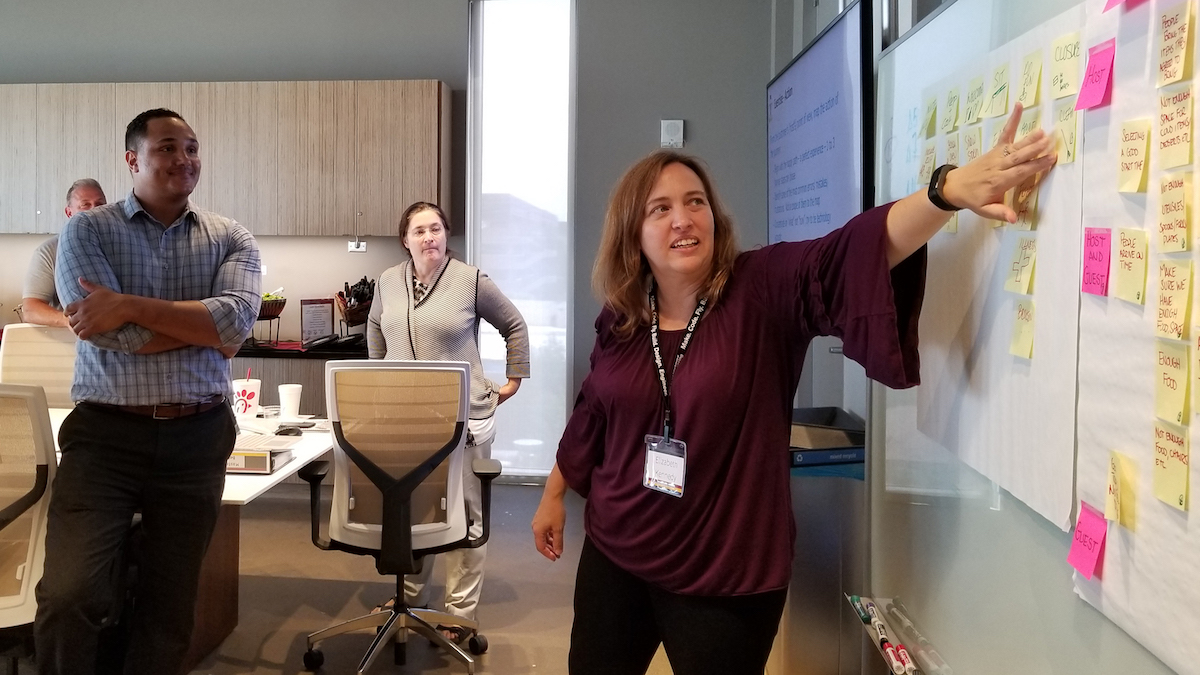

Together with their peers and expert faculty, Black Belts can build power thinking skills to generate new solutions by balancing innovation and the limitations of practical deployment in their own organizations.

The largest draw of the Fulton Schools program is the caliber of faculty who teach the Master Black Belt courses. Many have decades of experience in engineering management and implementing and teaching Six Sigma concepts. Others are expert researchers in industrial engineering and statistics.

“Students in the program have the opportunity to learn and interact with world-renowned faculty and industry professionals, giving them a great opportunity to not only learn from the best, but consult with them and address their specific challenges,” Heredia says.

ASU alumnus Garry L. Lewicki, an associate technical fellow and senior quality engineer at the Boeing Co. in Mesa, Arizona, has worked with ASU to coordinate Six Sigma training for his team. In 2018, he sought out the ASU Master Black Belt program to take his Black Belt training to the next level. He knew exactly where he wanted to get his certification and who he wanted to learn from.

“I know the quality of these individuals [teaching the courses], and when you have the opportunity to learn from the likes of Doug Montgomery and Dan Shunk, why would you consider anywhere else?” Lewicki says.

Shunk, a professor of industrial engineering, has spearheaded systems engineering continuing education efforts for companies such as General Dynamics and has decades of experience researching and teaching the concepts behind successful Six Sigma implementation.

Montgomery, a Regents’ Professor of industrial engineering and statistics and ASU Foundation Professor of industrial engineering, has an extensive history working in the industrial engineering sector and is a research leader in industrial statistics.

Jim Boblett, director of operational excellence at Viant Medical who completed the 2018 Master Black Belt certification program at ASU, says he learned many new opportunities to incorporate Six Sigma practices in his organization’s Operational Excellence rollout.

“Dr. Shunk taught us his VSAT [value-based strategic assessment tool] methodology and it will bring a change that I had not previously thought about and will be extremely beneficial in our OpEx deployment; Dr. [Lisa] Custer’s Master Black Belt deployment strategy is perfect for a new deployment or even a redo of a previous rollout,” Boblett says. “The opportunity to receive instruction from Dr. Montgomery is worth taking the program by itself, but with Dr. [Michelle] Mancenido assisting, the coverage of statistics is very well done!”

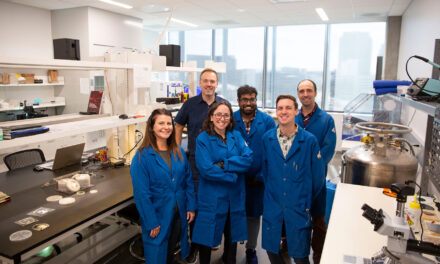

Master Black Belt certification program participants work together to master the advanced technical, leadership and Operational Excellence skills needed to be effective change makers. Photo courtesy of the Global Outreach and Extended Education office

Along with faculty, working with other motivated Black Belts enrolled in the program can help gain new perspectives on how to apply Six Sigma tools.

“Students are able to learn from their peers and explore how other organizations have successfully solved similar challenges, thus the professional network students are able to form during their program is highly unique,” Heredia says.

As Black Belts are already very involved members of their organizations working to implement Six Sigma projects, the Fulton Schools program helps them balance certification in their current role in an intensive, five-day on-campus program that involves lecture, discussion, activities and presentations.

The Master Black Belt program then builds on the Fulton Schools’ strengths as a top 10 online engineering graduate program by providing additional online courses. Master Black Belts-in-training can use these courses, which cover additional topics than the core courses, to customize the knowledge they need to best help their organizations. Participants can choose from one or all courses in Lean Great Belt, design of experiments, response surface methodology, design for Six Sigma and forecasting time series analysis.

Finally, after completing the on-campus experience and online training, participants complete a white paper instead of an additional project. The white paper is a high-level report on how to deploy Six Sigma specifically within their organization. Participants identify a problem statement, define a tactical approach and demonstrate technical tools and methods, and how they will be used to implement the plan.

Montgomery calls it the 20-page version of an elevator speech.

“It’s a paper that is, in a sense, a diagnostic study of what’s going on in your business, what the gaps are, what the opportunities are and what needs to be done to accelerate Lean Six Sigma or other Operational Excellence tools within your business,” he says.

Overall, participants get a variety of experiences and tools to help them lead organizational improvements and further their careers.

“The knowledge imparted during this program will have the ability to improve your current understanding of Six Sigma methodologies and Operational Excellence,” Boblett says. “No matter your role — current or desired — there is something for everyone to take the next steps in their career.”