Innovative aircraft design earns Air Devils top 10 finish

Each year, the American Institute of Aeronautics and Astronautics, or AIAA, hosts a Design/Build/Fly competition, inviting students around the world to design, fabricate and demonstrate the flight capabilities of an unmanned, electric-powered, radio-controlled aircraft that can best meet the specified mission profile.

The Air Devils student organization represents the Ira A. Fulton Schools of Engineering at Arizona State University in the AIAA International Design/Build/Fly competition. Of the 127 schools with teams participating in the competition, ASU’s Air Devils won seventh place overall.

The 2022 competition, hosted in Wichita, Kansas, was the first to be held in person since the start of the COVID-19 pandemic. The AIAA presents a different design challenge to its competitors every year. This year’s challenge was to develop an aircraft that could successfully deliver environmentally sensitive vaccine vial packages.

“Since aerospace engineering major capstone projects are paper studies this club represents a great opportunity for aerospace engineering majors to actually design and construct an airplane for a competitive assessment,” says Timothy Takahashi, the Air Devils’ advisor and an aerospace engineering professor of practice in the School for the Engineering of Matter, Transport and Energy, one of the seven Fulton Schools.

Air Devils members come from a variety of backgrounds, each having their own influence that makes them best suited to work on certain components of the aircraft. But students still often face challenges that require them to learn completely different skills. This year, the aircraft’s payload handling system presented a challenge to the team members, who experimented with new software and techniques to build an effective device.

The Air Devils’ aircraft on a test flight before the competition. Photographer: Timothy Takahashi/ASU

“The competition this past year introduced payload challenges that the team has never encountered,” says Max Stauffer, the outgoing president of Air Devils who recently graduated with a bachelor’s degree in aerospace engineering.

“The rules called for a challenging mission where the aircraft must carry and individually deploy a shock-sensitive box, then take off and fly an entire lap between deployments,” he says. “This requires careful handling of the payload boxes and fine control of how many are deployed at any time. This complexity is why we opted for individual claw mechanisms controlled by an Arduino-based microcontroller.”

This decision was only the beginning of the challenge, however. Each step of development was precluded by thousands of simulations team members used to understand the interaction between specifications like payload weight and takeoff distance or endurance.

“The mission system design was highly mechanical in nature and was one of the most complicated subsystems the team has ever taken on,” Stauffer says.

The system centered on a set of claw arms driven by a small motor through a geared drive train which could carefully drop the shock-sensitive boxes representing environmentally sensitive vaccine vial packages. Each claw arm was controlled by a microcontroller.

“The club had never used a microcontroller in this way,” Stauffer says. “While it was very challenging with many lessons learned, we were able to successfully complete our missions at the competition.”

It is this experience with real-world applications — the malfunctioning, the misfiring, all of the worst-case scenarios — that Stauffer says provided him the greatest learning experience during the competition.

“With our aircraft we originally planned to fly with six shock-sensitive payloads. We traveled to the competition expecting to deploy four, but we successfully deployed two on the flight line,” Stauffer says. “Despite this, we placed in the top 10 teams. While I did my best to account for underperformance early on, there are always more elements you must consider and account for to achieve whatever the desired outcome might be.”

Not every challenge the Air Devils faced was related to the construction of the team’s aircraft.

“Travel to Kansas with a large airplane and an entourage of students was a challenge,” Takahashi says. “We had a caravan of four vehicles from Tempe to Wichita loaded with students, the airplane and spare parts. Stauffer had car trouble on the way, and his car had to be towed into Wichita.”

Next year’s AIAA Design/Build/Fly competition will be in Tucson, so the Air Devils expect both a shorter journey to the competition and another chance to earn flying colors among their peers.

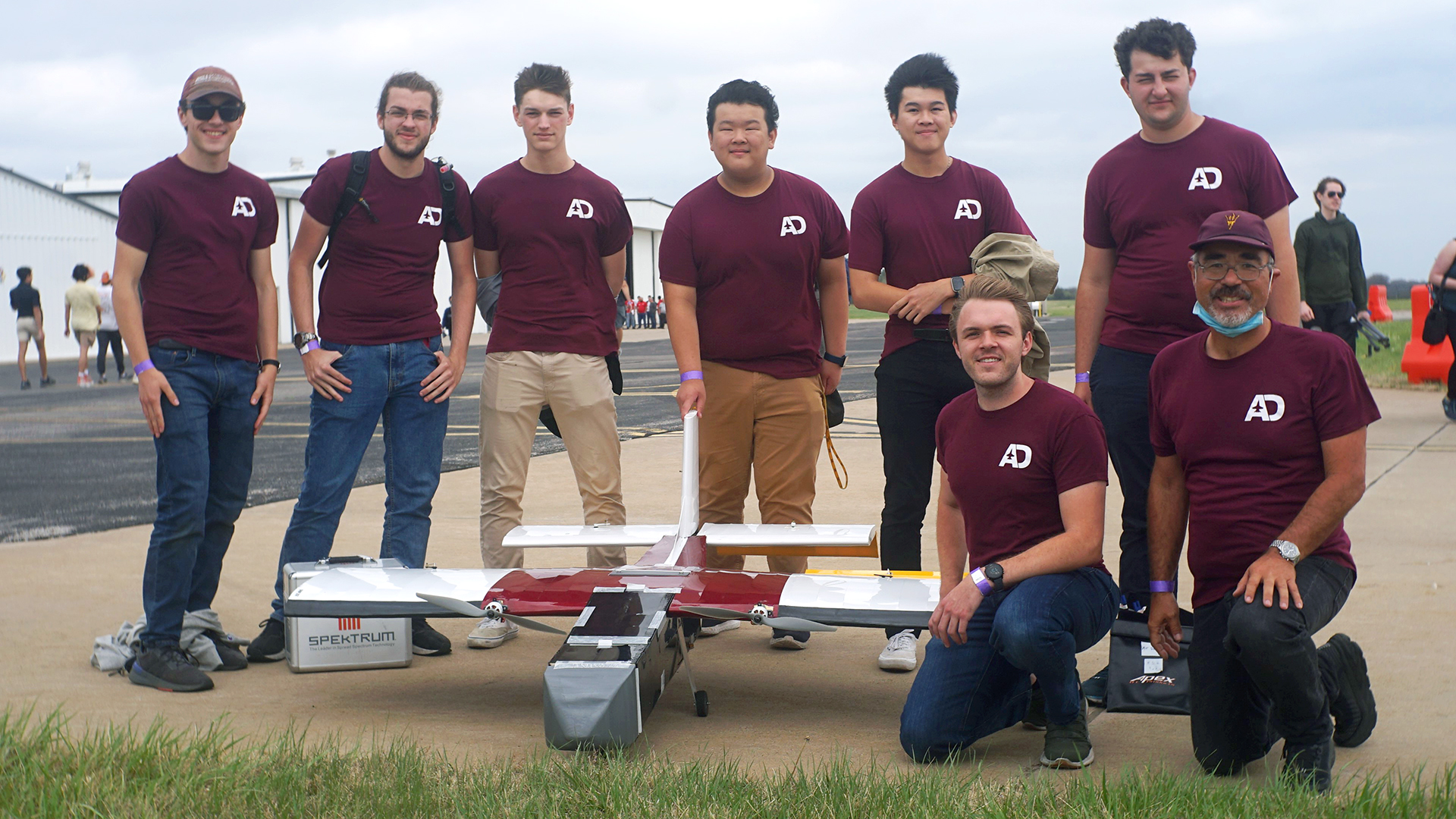

The Air Devils 2022 AIAA Design/Build/Fly team ready for take off. Pictured, from left to right, back row: Zachary Norris (incoming Air Devils president), Jack Griffin, Lucas VanNoord, Curtis Chan, Nicholas Cheng, Lucas Guaglardi. Pictured, from left to right, front row: Max Stauffer (outgoing Air Devils president), Timothy Takahashi (faculty advisor). Photo courtesy of Air Devils.