Unlocking the recipe for corrosion-resistant alloys

Above: Stainless steel resists corrosion such as rust much better than other metals like iron, as with this rusty bolt. Corrosion resistance is a rare property for most alloys as they’re usually designed for other mechanical properties, but Arizona State University Professor Karl Sieradzki and a multidisciplinary, multi-university team developed a theory to help materials scientists design better alloys that can resist corrosion. Image courtesy of Shutterstock

Almost all metals and alloys eventually corrode. For common things such as cars and metal gates, corrosion is just part of normal wear and tear. But on the other end of the spectrum, corroding metallic parts in aircraft, biomedical implants or nuclear power plant components could have serious consequences.

Karl Sieradzki, a professor of materials science and engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, worked with a multidisciplinary, multi-university team to develop the first guide for creating new alloys, or combinations of metals, with corrosion-resistant properties. Results of this research have been published in the journal Nature Materials.

“Alloys are typically never designed for their corrosion-resistant properties, mainly because we haven’t had a good way of adding corrosion properties into the design criteria,” Sieradzki says. “So, this may be a good first step in providing new design criteria for corrosion that fits into a general scheme for designing new alloys for both mechanical property behavior and corrosion resistance.”

The research paper titled “A percolation theory for designing corrosion-resistant alloys” describes Sieradzki’s work with researchers from the University of Toronto, Argonne National Laboratory, Johns Hopkins University and Drexel University to unravel the physics necessary to potentially unlock the recipes for next-generation, corrosion-resistant alloys. The work was funded in part by the National Science Foundation and an Office of Naval Research Multi University Research Initiative, or MURI, grant.

Stainless steel is an iron, chromium and nickel alloy that is resistant to corrosion. This unique property is provided by a film that forms as the result of a high enough concentration of chromium atoms on the surface that chemically bond to oxygen to “percolate,” or form a continuous chromium-oxide layer of protection. This passivation layer can “self-heal” when scratched, which means corrosion such as rust doesn’t get a chance to take hold.

But stainless steel’s corrosion-resistant property is rare. Other components such as silicon can, in principle, also be used for passivation, but they’re difficult to integrate effectively and have been used for corrosion-protection purposes only in alloys created in laboratories.

Even though stainless steel was developed more than 100 years ago, little has been known about why a certain concentration of chromium in the alloy leads to the development of a passive film.

Industry and government agencies want new alloys that use less chromium, which will improve cost savings and achieve better sustainability. For those reasons, new alloys that use three to five or more elements — known as multi-principal element alloys — are seen as the next big thing in materials science. A combination of more elements means additional desirable properties could be achieved in the alloys including corrosion resistance while using less chromium.

So far, materials scientists have had no way to specifically design corrosion-resistant forms of these new alloys with different metals.

“There have been a number of theories that explain why you need a certain amount of chromium in stainless steel to make it behave in the way it does,” Sieradzki says, “but they contained nothing quantitative and can’t be used to design new alloys.”

Instead of analyzing the passivation layer itself, as others have done, Sieradzki and his collaborators have looked at the properties of the underlying alloy to understand what drives the process. More recently, he and the research team developed a theory to predict how much of a certain element, like chromium, is needed to achieve passivation in a number of alloys, including stainless steel and other experimental alloys.

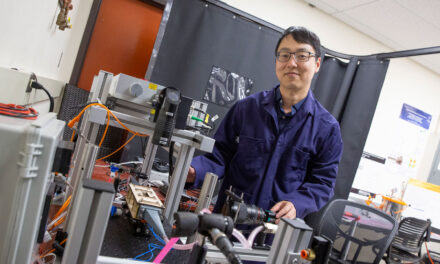

“That’s why we’ve had success in our modeling where others have failed,” says Sieradzki, who also collaborated with ASU Assistant Professor Houlong Zhuang and ASU graduate students Yusi Xie, Ashlee Aiello and Duo Wang, in addition to researchers Dorota M. Artymowicz and Roger C. Newman at the University of Toronto, Pietro P. Lopes at the Argonne National Laboratory, James L. Hart and Mitra L. Taheri at Johns Hopkins University and Elaf Anber at Drexel University.

Prior to this theory, understanding passivation was like experimenting with cooking without an exact recipe, Sieradzki says. You know a new kind of cookie you want to bake needs flour and sugar, and you know a certain amount of sugar makes the cookie sweet. When making an alloy, materials scientists know a certain amount of chromium causes corrosion resistance, but they don’t always know specifically how much would make an effective recipe.

In stainless steel, layers of iron atoms in the material’s crystal lattice structure must be removed so that there remains a high enough surface concentration of chromium atoms close enough to each other to achieve passivation. The theory Sieradzki and the research team came up with helps to determine how many layers need to be removed by corrosion to achieve the correct concentration of corrosion-resistant elements at the surface of the alloy.

“If we have enough information with respect to the detailed crystal structure of the lattice, we can make predictions for how much [of an element] to put into the alloy to get good passivation behavior,” says Sieradzki, adding that the next steps of this research involve designing new alloys and detailed X-ray analysis of their atomic structures.

For two-element alloys, like iron-chromium, the recipe can’t be changed much at all. But multi-principal element alloys consist of several elements that can be present in different amounts, so the range in the recipe is much greater. As with a cookie recipe, you can have the correct ratio of flour to sugar, and also add in extras like chocolate chips and nuts to enhance its flavor.

“By changing the number of those elements, you can change the separation between chromium atoms in the alloy [and achieve passivation] with possibly less total chromium,” Sieradzki says.

So, if materials scientists are looking to create an alloy with certain strength and ductility (flexibility) characteristics, they may be able to achieve it with multi-principal element alloys, while at the same time produce good corrosion resistance.

This is a promising development for applications in which both mechanical properties and corrosion resistance are vital. The biomedical implant, aircraft and nuclear power generation and nuclear waste storage industries could all see great benefits from new corrosion-resistant alloys.

“The design of lightweight alloys would also be a huge plus,” Sieradzki says. “Magnesium is a metal that is very lightweight and there’s plenty of it around. The problem is that it corrodes, big time. If a ‘stainless magnesium’ alloy could be created, we could create lighter cars and start to think about using it as an alloy for structural components.”