Forging path for plant-based sustainable source of rubber and fuel

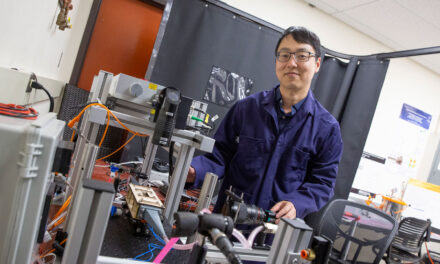

ASU engineer Amy Landis (right) will lead projects to promote the use of biomaterials as sustainable sources of rubber and fuels. Photo: Jessica Slater/ASU

Posted April 22, 2013

Arizona State University engineer Amy Landis has a pivotal role in a new potentially far-reaching effort to use biomaterial to produce rubber in a more environmentally and economically sustainable way.

She will lead the sustainability assessment for a four-year project teaming Cooper Tire & Rubber Company, Yulex Corporation, ASU and the U.S. Department of Agriculture (USDA).

The project has been awarded a $6.9 million grant through the Biomass Research and Development Initiative of the USDA and the U.S. Department of Energy.

The endeavor focuses on the guayule plant (pronounced why-you-lee), from which latex can be extracted and turned into rubber. It holds promise for being a feasible alternative to petroleum-based synthetics that are now the predominant form of rubber in tires and many other products using rubber.

In addition to producing rubber, guayule material could be used to make industrial, medical, consumer and energy products, as well as biofuels. Substantial use of the plant could reduce the United States’ dependence on producers in other countries for the nation’s supply of rubber.

Exploring full array of impacts

Landis is an associate professor in the School of Sustainable Engineering and the Built Environment, one of ASU’s Ira A. Fulton Schools of Engineering. She is also a senior sustainability scientist in the university’s Global Institute of Sustainability.

Her role in the guayule project is to help ensure its use will, in fact, be sustainable in multiple ways.

“Just because you are using a biomaterial does not guarantee what you do will be a ‘green’ venture,” Landis says. “I will be looking at the entire process of creating rubber products, from the agricultural process of growing and harvesting guayule, extracting and processing natural latex, and manufacturing natural rubber tires. The sustainability assessment will evaluate factors such as local impact on the land where guayule is grown and the how cultivation of the crop changes the landscape for the neighboring farmers.”

Her sustainability analysis will also take into consideration “human elements” and community impacts. “This involves looking at things like the potential for job creation and who will be employed throughout the process” of growing and processing guayule to make rubber on a large scale, as well as the implications for communities’ quality of life, she says.

“Our contribution to the sustainability assessment includes a complete life cycle assessment of natural rubber tires” she says. “We don’t want to ignore or overlook any short-term or long-term impact.”

Potentially far-reaching endeavor

Increased use of guayule could eventually offer a particular benefit for Arizona’s economy. The state is the center of operations for the project partner corporation Yulex, which is already producing some products using guayule, including mattresses and pillows.

The Yulex corporate headquarters is close to Phoenix Sky Harbor International Airport. Its manufacturing facility is in Chandler, and the company gets its supply of the plant from some of the eight or more commercial farmers growing the crop in Arizona.

The reach of the project promises to extend much further through lead project partner Cooper Tire and Rubber Company, which is the parent company of a family of companies in 11 countries that specialize in the design, manufacture, marketing and sales of passenger car and light truck tires. The Ohio-based company also has joint ventures, affiliates and subsidiaries that specialize in medium truck, motorcycle and racing tires.

Both Yulex and Cooper have developed company initiatives aimed at operating their enterprises in socially and ecologically responsible ways.

As part of the project, Landis will also explore the impacts of ramping up the use of nonlatex portions of the guayule plant to produce biofuel, bioenergy and fertilizers.

Boosting biobased energy and products

In a separate project, Landis will team with University of Pittsburgh chemical engineer Vikas Khanna on a sustainability research project being supported by a recent $350,000 grant to ASU from the USDA.

The project’s main thrust is to provide data to guide alignment of varying local, state and national policies to set consistent parameters for development and production of biofuels.

It’s part of a larger federal program aimed at spurring the production of bioenergy and biobased products, while at the same time ensuring the environmental and socioeconomic sustainability of such ventures.

Another of the program’s goals in promoting further development of biomaterials to produce fuel and energy is to create new markets for the nation’s agricultural products.

ASU is among universities selected to receive grants from the program through a competitive process. Applicants for the grant awarded to ASU included some of the top university sustainability research programs in the country, Landis says.

Media Contact:

Joe Kullman, [email protected]

(480) 965-8122

Ira A. Fulton Schools of Engineering