Stresses and strains on materials pose dangers

Posted: May 12, 2011

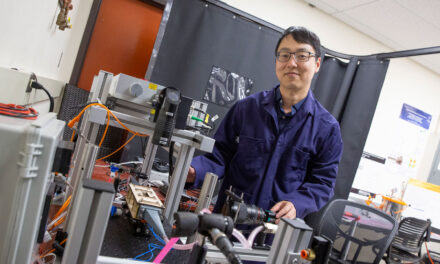

Nik Chawla, professor of materials science and engineering in the School for Engineering of Matter, Transport and Energy

In the wake of recent news about the roof of a Southwest Airlines jet ripping apart during a flight from Phoenix, Arizona State University engineer Nik Chawla talked about the causes of such dramatic incidents.

Often it’s a case of metal fatigue, the result of physical stress that degrades the resiliency of materials, explains Chawla, a professor of materials science and engineering in the School for Engineering of Matter, Transport and Energy, one of ASU’s Ira A. Fulton Schools of Engineering.

Repeated cycles of pressurization and depressurization exerted on aircraft in flight can produce enough strain over time to crack the aluminum alloys that make up the outer shell of many aircraft.

Chawla describes work he and other ASU researchers are doing to better predict the behavior of materials under various conditions. They’re developing advanced methods of detecting indications of materials fatigue, with the goal of preventing potentially catastrophic failures of materials.