Flexible hybrid electronics bend the rules of computing architectures

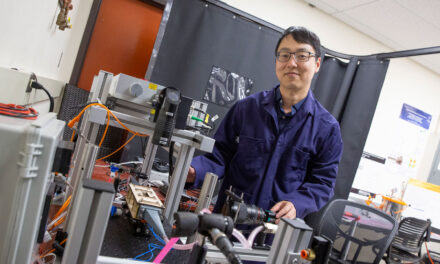

Umit Ogras

Typical computing platforms don’t bend, twist and flex the ways we humans do. Powerful silicon architectures in use today require rigidity, but the wearable, assistive and medical computing applications of the future would be most beneficial if they were flexible.

Umit Ogras, an assistant professor of electrical and computer engineering in Arizona State University’s Ira A. Fulton Schools of Engineering, is developing an innovative methodology and tools to optimize the design of flexible hybrid electronics — architectures that combine flexible elements and rigid silicon to overcome the performance limitations of purely flexible electronics. The work is supported by a $500,000, five-year National Science Foundation CAREER Award project.

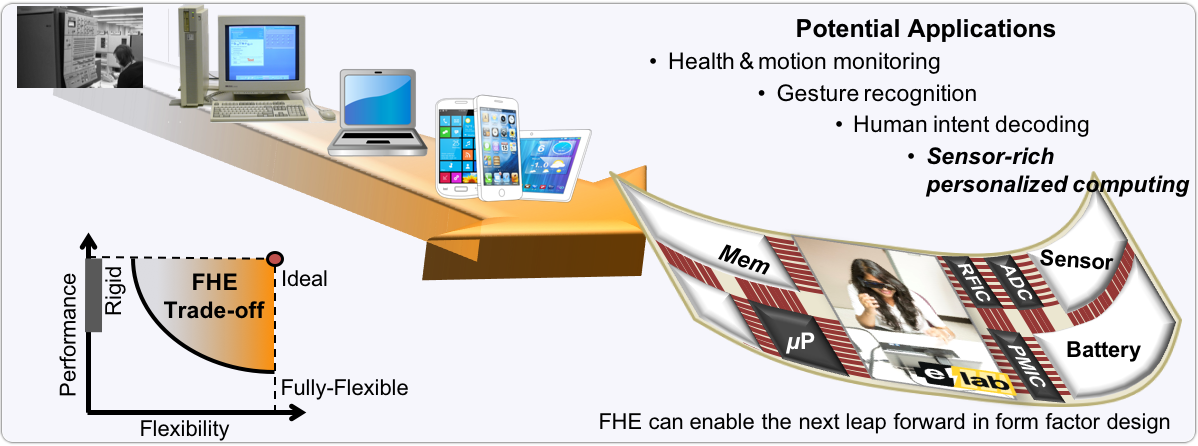

“Physical flexibility and stretchability expands the design space into an uncharted dimension,” Ogras says, “which introduces intricate trade-offs with the traditional power, performance and area metrics, but can also drive the next big leap forward in form factor design, similar to the shift from desktop and laptop computers to handheld devices.”

Purely rigid electronics like our smartphones boast high computing power, but lack the flexibility required for wearables. However, flexible thin-film transistors fall short on processing power.

It’s up to electronic systems designers to figure out how to combine silicon and flexible printed electronics for better-performing, mostly flexible systems.

“However, there are no proposed solutions for the systematic modeling and design of flexible hybrid electronic systems,” Ogras says.

Ogras is taking a new approach to the problem. He is constructing new tools that quantify flexibility as a metric in the design process.

“This will enable designers to find the optimal set of rigid integrated circuits, such as state-of-the-art silicon microprocessors, and flexible/stretchable devices such as sensors, antenna and displays, that implement the target functionality,” Ogras says. “Then, the rigid ICs will be integrated onto flexible or stretchable substrates using emerging interface techniques such as those developed at NextFlex.”

Flexible hybrid electronics have great potential for wearable computing, assistive technologies, the internet of things, body sensors and medical applications.

Flexible hybrid electronics display the next step in form factor evolution. This figure shows a system-on-polymer (SoP) proposal with flexible circuits, display and battery, and rigid integrated circuits, demonstrating an optimization of flexible and rigid parts to optimize performance. Graphic courtesy of Umit Ogras

“For example, flexible hybrid electronics can enable electronic patches equipped with motion, physiological and biochemical sensors, and wireless transceivers,” Ogras says. “These patches can be used to examine movement disorders at any time and anywhere, in stark contrast to the current practice, where a patient has to stay in a clinical environment.”

He hopes in the long term, flexible hybrid electronics can “deliver the functionality of current state-of-the-art mobile platforms and more in a truly pervasive form factor.”

Ogras says ASU is one of the leading institutions in the flexible electronics area, and collaborations with the Power One IC Research Center and Flexible Electronics and Display Center have greatly helped his NSF CAREER Award project development.