Novel optimization methods for efficient manufacturing

Above: With support from a National Science Foundation CAREER Award, Giulia Pedrielli, an assistant professor in the Ira A. Fulton Schools of Engineering at Arizona State University, will improve optimization methods for single-use, scalable individualized manufacturing systems to offer increased flexibility and efficiency in pharmaceutical production. Image courtesy of Shutterstock

Nine faculty members in the Ira A. Fulton Schools of Engineering at Arizona State University have received NSF CAREER Awards in 2021.

In applications such as gene therapy, targeted drug delivery and tissue reconstruction products are often produced with a high level of personalization, to the point of individual products.

The process of producing highly personalized pharmaceuticals, however, is extremely expensive, slow and inefficient due to manufacturing constraints.

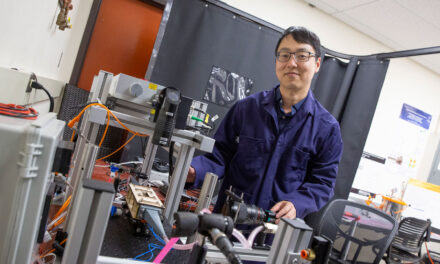

Giulia Pedrielli, an assistant professor of industrial engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, is working to improve optimization methods that can enable single-use scalable individualized manufacturing systems in a five-year, 2021 National Science Foundation Faculty Early Career Development Program (CAREER) Award.

Giulia Pedrielli

Instead of scaling up biopharmaceutical manufacturing systems, Pedrielli’s research focuses on “scaling out” the systems, allowing for a large variety of small-quantity, highly specialized pharmaceuticals to be manufactured simultaneously.

“Efficient biomanufacturing has been traditionally associated with the motto ‘one fits all’ where drugs are produced to work for large populations. This resulted in a low flexibility industry where productions need to be performed in large batches in order to be economically viable and stable,” Pedrielli says. “What we’re trying to create here is the total opposite — a fast, energized system for controlling the production of a high number of small-quantity products.”

The processes to be optimized for large-scale systems of interacting small production units are extremely complex. Nonetheless, data and simulations are available to evaluate them.

New methods are needed to optimally operate this new class of systems, and Pedrielli proposes “gray box” techniques: algorithms that can solve highly nonlinear nonconvex high dimensional problems embedding structural information from the process being optimized.

“Black box optimization is a family of techniques that can solve an optimization problem without knowing the mathematical form of the reward,” Pedrielli says. “The only thing you can do is to test the system and evaluate its response. Achieving high performance in terms of quality of the solution, interpretability, and computational time is a long-standing problem in optimization and control, but we bring new ideas in terms of how can we use black-box optimization using measurements and underlying models to accelerate our learning.”

Because black box models do not contain information on the system dynamics, are very general and can ideally be applied to any problem. But they are inefficient and sometimes difficult to interpret.

“My goal is to bring structure to black-box algorithms and make it more of a grey box, so to speak,” Pedrielli says. “Bringing structure into the box makes the solution and the algorithm itself more interpretable. This is important in all categories learning-based method and becomes crucial when we want to apply these techniques to critical systems.”

Outside of the biopharmaceutical industry, Pedrielli’s work to improve optimization methods gray box optimization can impact other industries, including the semiconductor and aerospace industries, areas where she is already working in the context of other projects.

“My hope is that this kind of framework and these techniques that we are developing can really support this idea that we can produce a large variety of products in very small quantities in a stable manner,” Pedrielli says.

Pedrielli’s research expertise is in algorithm design and analysis, but through her collaboration with colleagues at the Biodesign Institute as well as with Professor Nicholas Dunne at Dublin City University, she was inspired to take on a project that impacts the biopharmaceutical industry.

“When I started as an assistant professor at ASU, I was most passionate about simulation and optimization. I didn’t know anything about biomedical products,” Pedrielli says. “Being able to collaborate with so many different people across different disciplines has really helped me build beyond my algorithmic knowledge. What motivated me to write a good proposal was to have in my hands what I feel is a potentially disruptive application that could positively impact the lives of many.”